Three-source intumescent flame retardant, hybrid intumescent flame retardant grafted therewith, and their preparation and application

An intumescent flame retardant, an integrated technology, applied in the field of intumescent flame retardants, can solve the problems of the influence of polymer mechanical properties, high water solubility, poor polymer compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

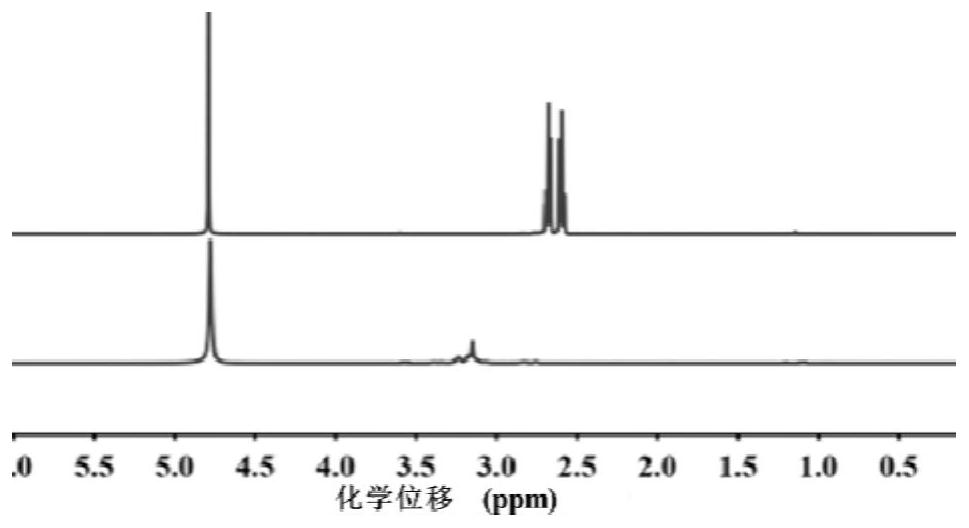

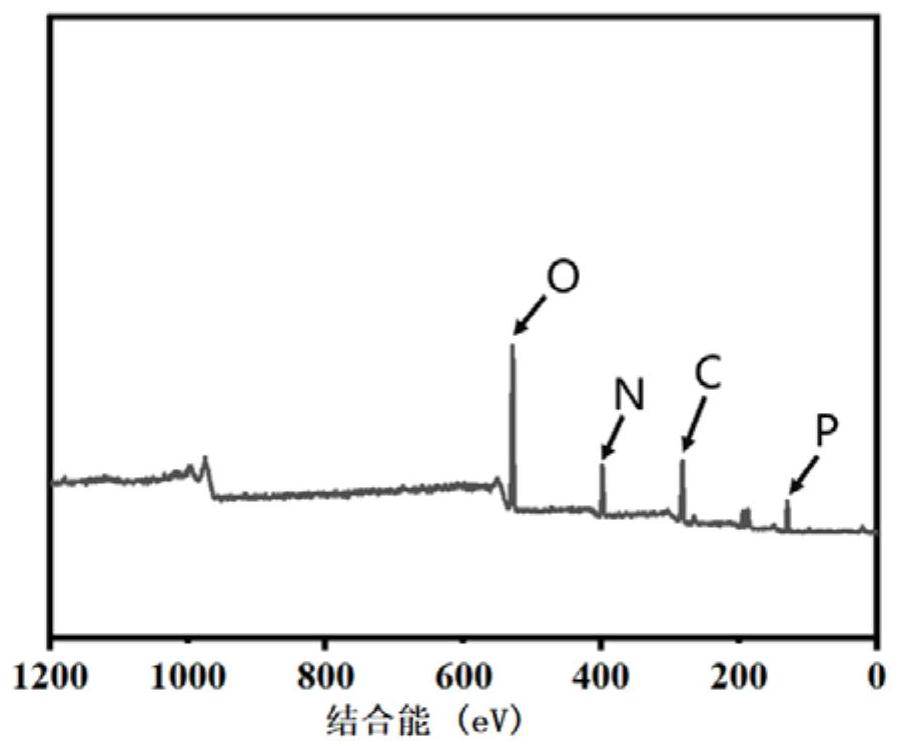

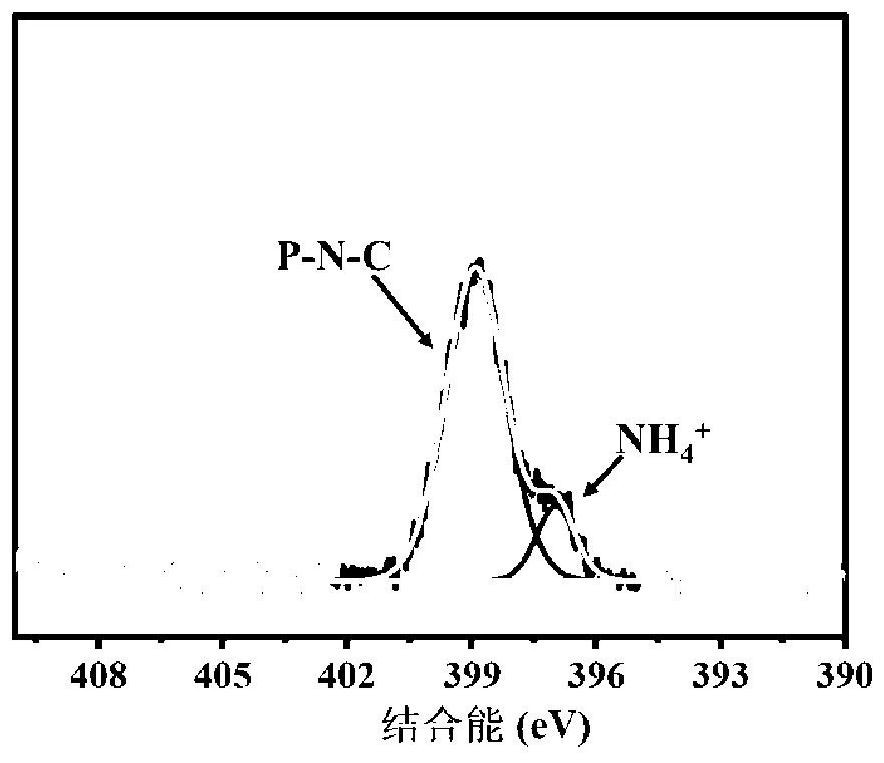

[0058] Add 1 mol of ethylenediamine and 2 mol of triethylamine into toluene and mix well, then add 1 mol of phosphorus oxychloride dropwise at 0°C with stirring, and heat to 70°C to continue the reaction for 6 hours; after the toluene is removed by rotary evaporation, Then add an aqueous solution containing 2 mol of pyridine, react at 100°C for 6 hours, cool down to 5°C to remove water by suction filtration, and wash with ethanol three times to obtain the three-source intumescent flame retardant FR-1.

Embodiment 2

[0060] Add 1 mol of ethylenediamine and 2 mol of triethylamine into acetonitrile and mix well, then add 1 mol of phosphorus oxychloride dropwise at 3°C with stirring, and heat to 70°C to continue the reaction for 7 hours; after the acetonitrile is removed by rotary evaporation, add Ammonia solution containing 2 mol of ammonia reacted at 90°C for 12 hours, cooled to 5°C to remove water by suction filtration, and washed with ethanol three times to obtain the three-source intumescent flame retardant FR-2.

Embodiment 3

[0062] Add 1 mol of propylenediamine and 2 mol of triethylamine into toluene and mix well, then add 1 mol of phosphorus oxychloride dropwise at 2°C with stirring, and heat to 70°C to continue the reaction for 6 hours; after the toluene is removed by rotary evaporation, Then add ammonia solution containing 2 mol of ammonia, react at 90°C for 10h, cool down to 5°C to remove water by suction filtration, wash with ethanol three times to obtain the three-source intumescent flame retardant FR-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com