A flame-retardant heat-resistant reinforced polylactic acid composition and its preparation method

A technology of enhanced heat resistance and polylactic acid, which is applied in the field of polylactic acid materials, can solve problems such as mechanical property degradation and heat resistance effects, and achieve the effects of less damage to the environment and human body, high flame retardant effect, and small production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

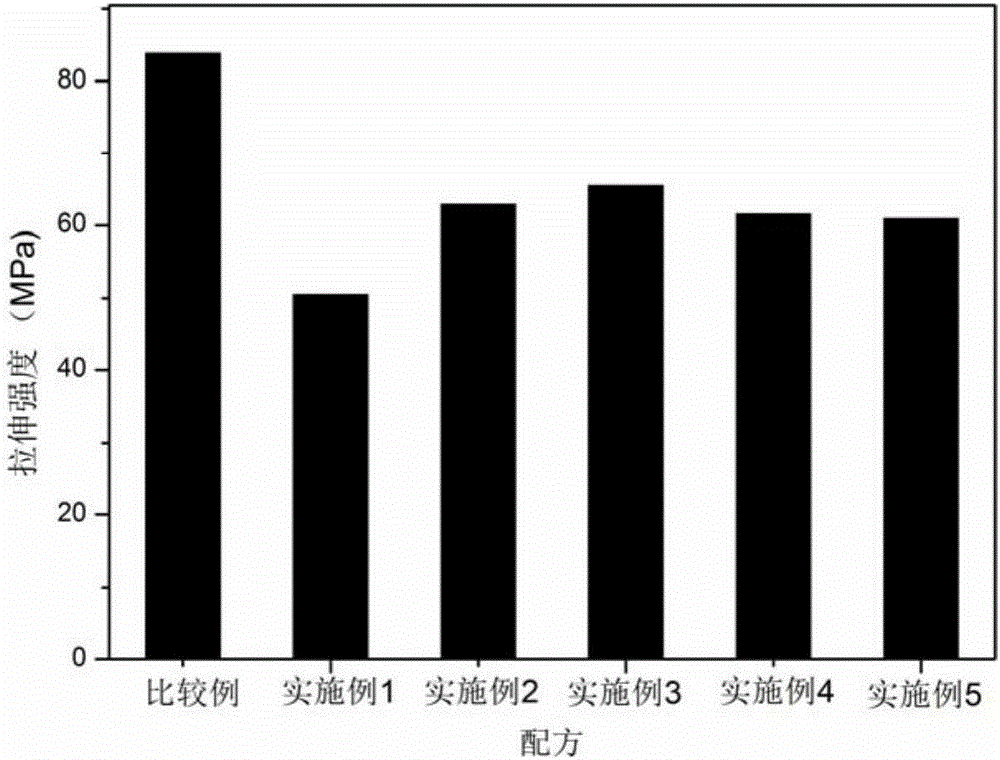

[0029] Example 1: Weigh 34g of polylactic acid pellets, 6g of oligomeric aryl phosphate (PX-220), at the extrusion temperature of 175°C in the first zone, 176°C in the second zone, 177°C in the third zone, and 177°C in the fourth zone Under the conditions, the polylactic acid composition is obtained by adding a conical twin-screw extruder, extruding and cooling. Measured according to GB / T2406-1993 standard test method, the limiting oxygen index is 33%. Define the temperature when the mass loss is 5wt% as the initial decomposition temperature, the initial decomposition temperature of the material is 334 ° C, see the tensile strength figure 2 .

Embodiment 2

[0030] Example 2: Weigh 34g of polylactic acid pellets, 4.8g of oligomeric aryl phosphate (PX-220) and 1.2g of vinyl silicone resin, and the extrusion temperature is 175°C in the first zone, 176°C in the second zone, and 176°C in the third zone Under the conditions of 177°C and 177°C in the fourth zone, feed into a conical twin-screw extruder, extrude and cool to obtain a polylactic acid composition. Measured according to GB / T2406-1993 standard test method, the limiting oxygen index is 32.2%. Define the temperature when the mass loss is 5wt% as the initial decomposition temperature, the initial decomposition temperature of the material is 342 ° C, see the tensile strength figure 2 .

Embodiment 3

[0031] Example 3: Weigh 34g of polylactic acid pellets, 3.6g of oligomeric aryl phosphate (PX-220) and 2.4g of vinyl silicone resin, and the extrusion temperature is 175°C in the first zone, 176°C in the second zone, and 176°C in the third zone Under the conditions of 177°C and 177°C in the fourth zone, feed into a conical twin-screw extruder, extrude and cool to obtain a polylactic acid composition. Measured according to GB / T2406-1993 standard test method, the limiting oxygen index is 30.5%. Define the temperature when the mass loss is 5wt% as the initial decomposition temperature, the initial decomposition temperature of the material is 342 ° C, see the tensile strength figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

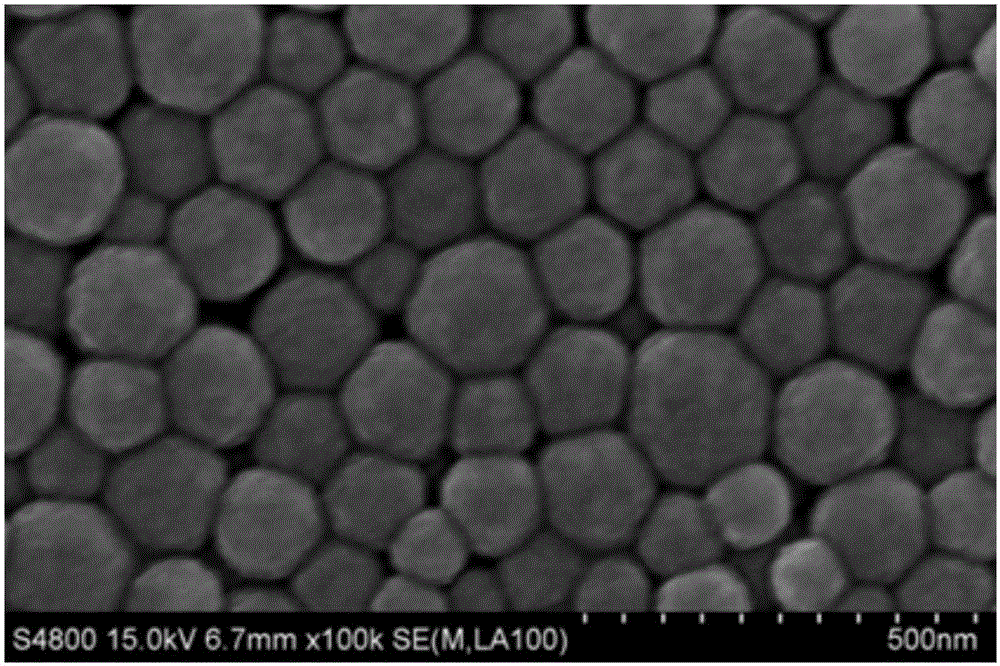

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com