LCP/HBN composite material and preparation method thereof

A technology of composite materials and polymer materials, which is applied in the field of LCP/HBN composite materials and its preparation, can solve the problems of long thermal history of composite materials, easy degradation of polymers, poor dispersion of thermally conductive fillers, etc., to improve thermal stability, Improve the bulk density, improve the effect of dispersion and mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

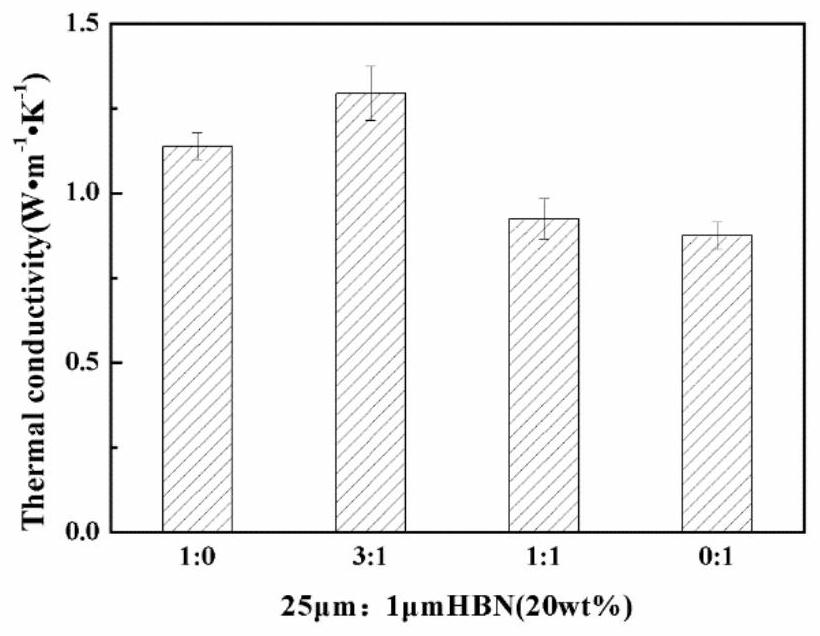

[0033] This example provides four preparation methods for LCP / HBN composite materials.

[0034] According to the formula of Sample 1 and Comparative Samples 1 to 3 shown in Table 1, the ingredients were mixed and mixed in a high-speed mixer of 35000 r / min for 5 minutes, and then melt-blended using a polymer material plasticization and transportation equipment based on extensional rheology. , the temperature of each section is 230-300-310-310 ° C, the rotor speed is 45 rpm, extrusion molding, cooling, drying, that is, four kinds of LCP / HBN composite materials are obtained.

[0035] The above materials were dried in a vacuum drying oven at 130° C. for 6 hours, and the dried LCP / HBN composite sheets were arranged in a fixed direction, which was consistent with the melt flow direction during extrusion. The samples were prepared by hot pressing with a flat vulcanizer, the temperature was 300 °C, the preheating time was 15 min, the hot pressing was 3 min, and the cold pressing was 5...

Embodiment 2

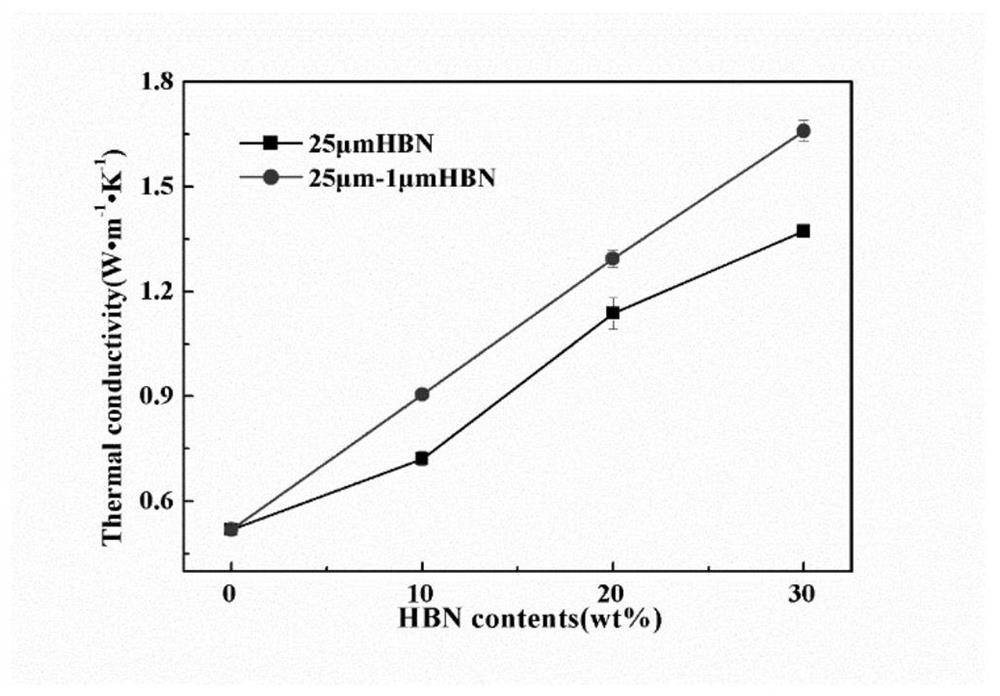

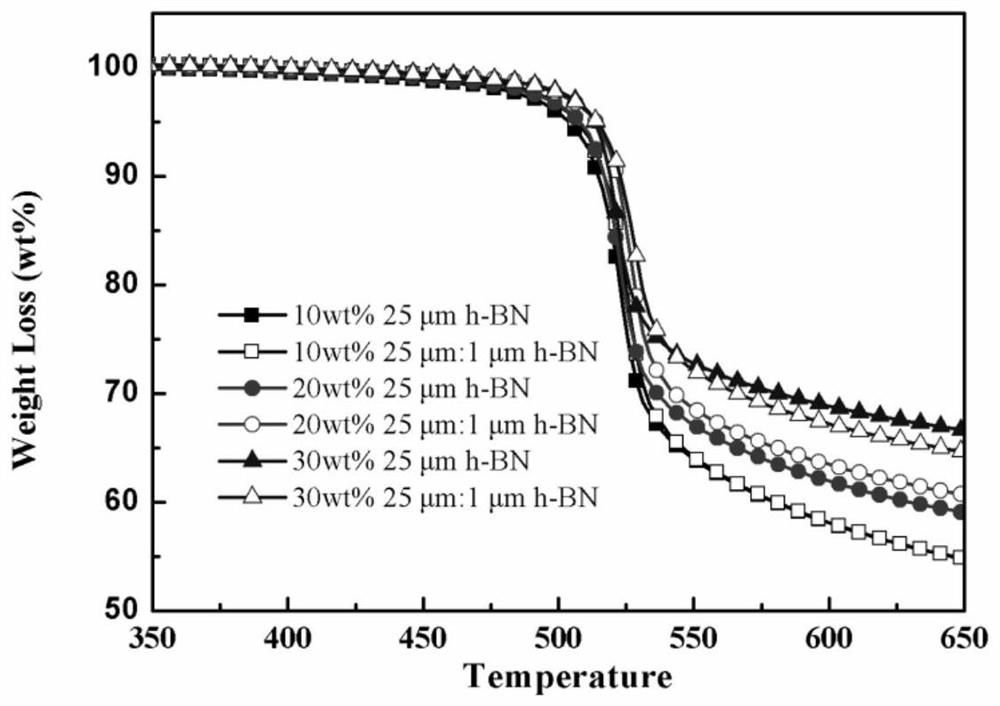

[0039] This embodiment provides 6 kinds of LCP / HBN composite materials and preparation methods thereof.

[0040] According to the formulas of samples 1 to 3 and comparative samples 1, 4 and 5 shown in Table 2, the ingredients were mixed, mixed in a 35000r / min high-speed mixer for 5 minutes, and then plasticized and transported using an extensional rheology-based polymer material. The equipment is melt-blended, the temperature of each section is 230-300-310-310°C, the rotor speed is 45 rpm, extrusion molding, cooling and drying, that is, 6 kinds of LCP / HBN composite materials are obtained.

[0041] The above materials were dried in a vacuum drying oven at 130° C. for 6 hours, and the dried LCP / HBN composite sheets were arranged in a fixed direction, which was consistent with the melt flow direction during extrusion. The samples were prepared by hot pressing with a flat vulcanizer, the temperature was 300 °C, the preheating time was 15 min, the hot pressing was 3 min, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com