A kind of flame-retardant nanocellulose containing phosphazene group, preparation method and flame-retardant polylactic acid thereof

A technology of nanocellulose and nitrile group, applied in the field of flame retardant nanocellulose, preparation, and flame retardant polylactic acid, can solve the problems of low thermal stability, high raw material cost, low flame retardant efficiency, etc., and achieve flame retardant efficiency High, initial decomposition temperature, the effect of improving carbon formation rate and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

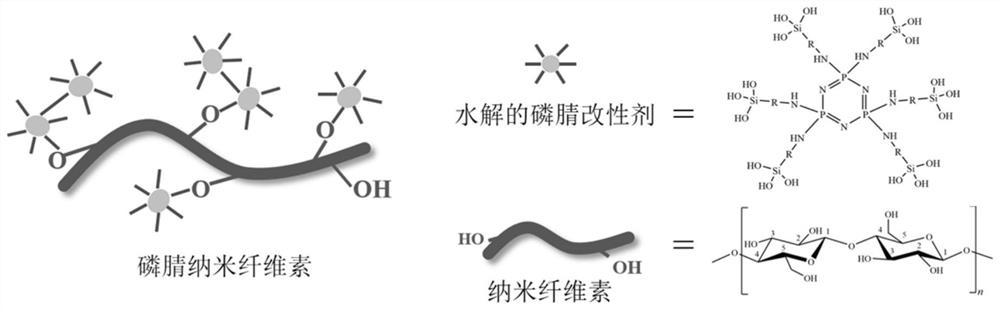

[0032] Step (1): adding 9.40 g of phosphazene modifier to a mixed solution of 50 ml of water and 50 ml of absolute ethanol, and ultrasonicating for 30 minutes at 10° C. to obtain a hydrolyzed phosphazene modifier;

[0033] Step (2): slowly drop the hydrolyzed phosphazene modifier obtained in step (1) into a mixture of 9.40g of cellulose nanofibers (CNF) and 90ml of cyclohexane;

[0034] Step (3): after the dropwise addition is completed, the temperature is heated to 40° C., and the reaction is stirred and refluxed for 10 hours;

[0035] Step (4): the mixture obtained in step (3) is allowed to stand for cooling, after the solid is completely separated out, suction filtration, and vacuum drying to obtain flame-retardant nanocellulose containing phosphazene groups;

[0036] Step (5): premix the above-mentioned flame retardant nanocellulose and piperazine pyrophosphate (PPAP) in a mass ratio of 1:10 to prepare a compound flame retardant, and then take 5 parts of the compound flame...

Embodiment 2

[0039] Step (1): adding 44.5 g of phosphazene modifier to a mixed solution of 10 ml of water and 100 ml of absolute ethanol, and ultrasonicating for 5 minutes at 40° C. to obtain a hydrolyzed phosphazene modifier;

[0040] Step (2): slowly add the hydrolyzed phosphazene modifier obtained in step (1) dropwise to a mixture of 8.9 g of cellulose nanocrystals (CNC) and 50 ml of toluene;

[0041] Step (3): after the dropwise addition is completed, the temperature is heated to 20° C., and the reaction is stirred and refluxed for 18 hours;

[0042] Step (4): the mixture obtained in step (3) is allowed to stand for cooling, after the solid is completely separated out, suction filtration, and vacuum drying to obtain flame-retardant nanocellulose containing phosphazene groups;

[0043] Step (5): premix the above flame retardant nanocellulose and melamine polyphosphate (MPP) in a mass ratio of 10:1 to prepare a compound flame retardant, and then take 20 parts of the compound flame retard...

Embodiment 3

[0046] Step (1): adding 20.5 g of phosphazene modifier to a mixed solution of 15 ml of water and 75 ml of absolute ethanol, and ultrasonicating for 15 minutes at 20° C. to obtain a hydrolyzed phosphazene modifier;

[0047] Step (2): slowly drop the hydrolyzed phosphazene modifier obtained in step (1) into a mixture of 8.2 g of cellulose nanocrystals (CNC) and 100 ml of absolute ethanol;

[0048] Step (3): after the dropwise addition is completed, the temperature is heated to 80° C., and the reaction is stirred and refluxed for 12 hours;

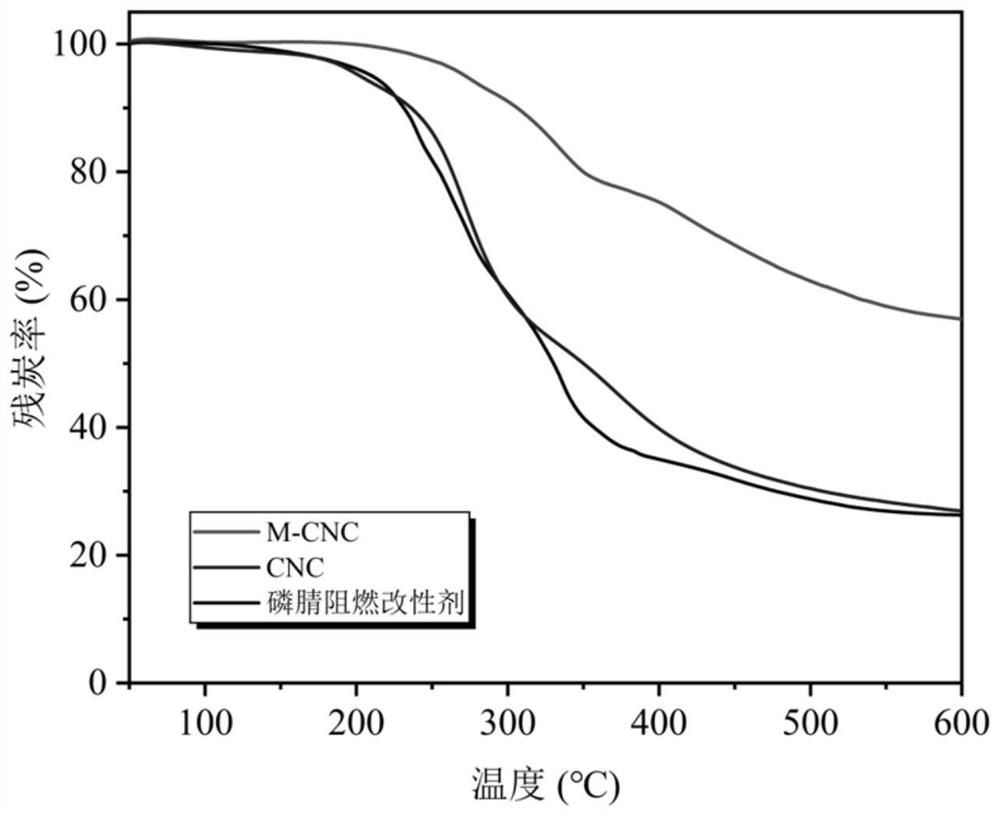

[0049]Step (4): the mixture obtained in step (7) is allowed to stand for cooling, and after the solid is completely separated out, suction filtration, and vacuum drying to obtain flame-retardant nanocellulose (M-CNC) containing phosphazene groups;

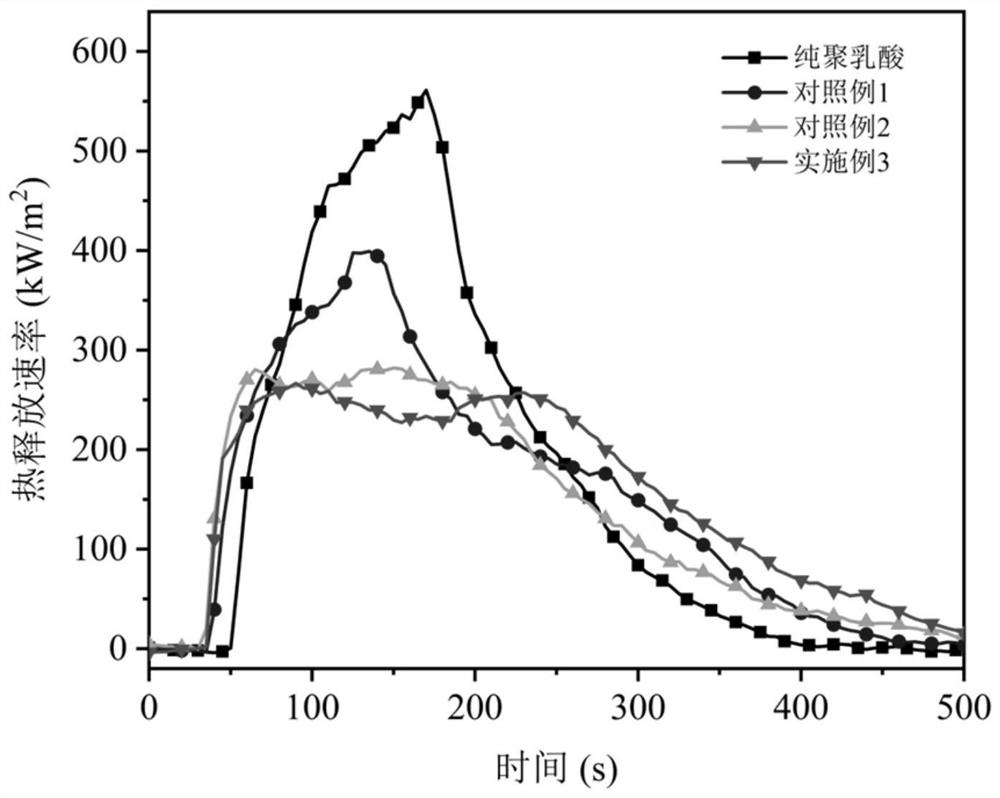

[0050] Step (5): M-CNC and ammonium polyphosphate (APP) are pre-mixed in a mass ratio of 3:7 to make a compound flame retardant, and then 10 parts of the compound flame retardant and 90 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com