Preparation method of high-compression-resistance fire-resistant composite epoxy foam

A fire-resistant, composite ring technology, applied in the field of epoxy foam, can solve the problems of reducing the cell size, strengthening the cell wall, reducing the activity of benzyl hydroxyl, etc., to increase the initial decomposition temperature, improve flame resistance, and shorten the gel the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

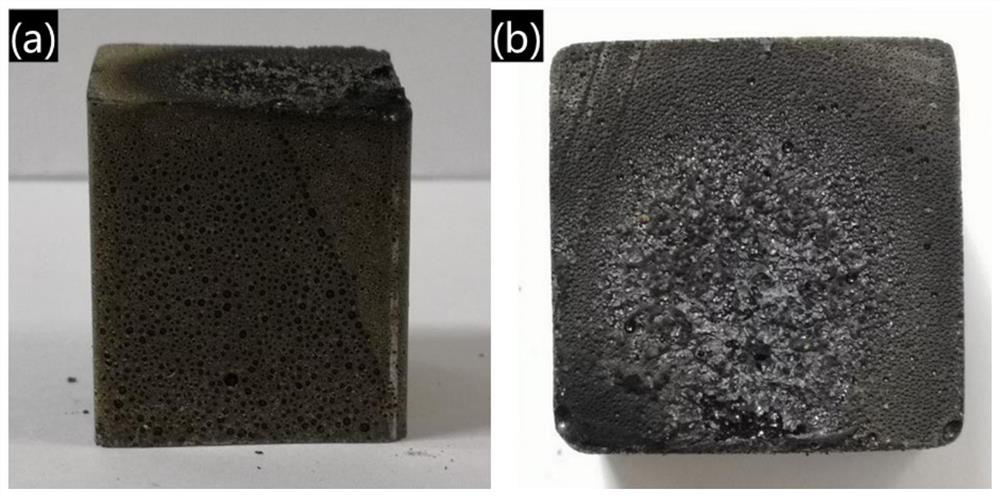

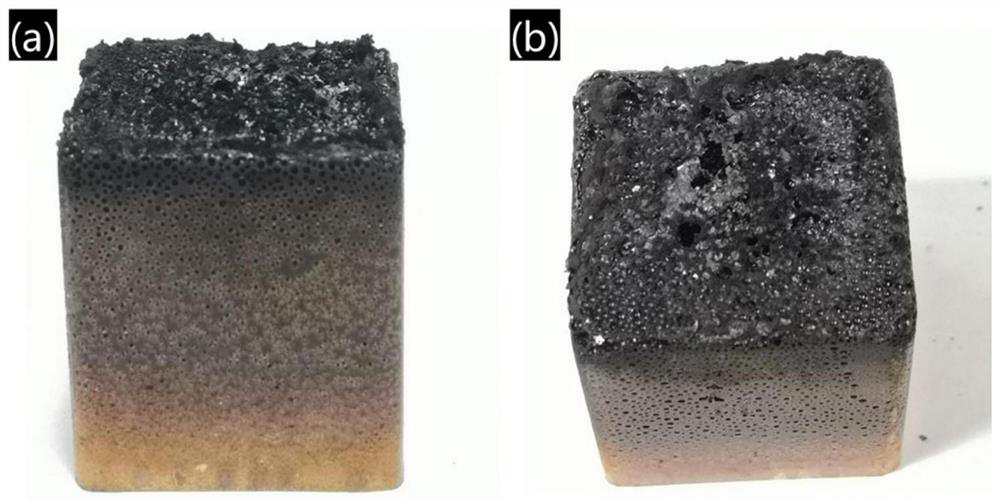

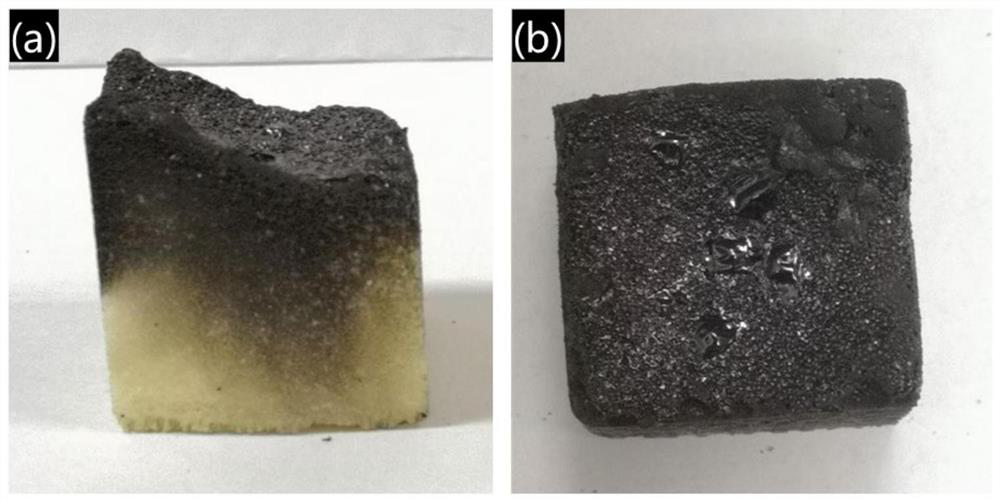

Image

Examples

Embodiment 1

[0022] The organic solvent selects n-butanol for use, the mol ratio of bisphenol A diglycidyl ether and formaldehyde is 1:1.2, the mass ratio of ammonia water and bisphenol A diglycidyl ether is 1:50; the mass ratio of boric acid and bisphenol A diglycidyl ether is 1:50; The molar ratio is 1:5; N,N-dimethylformamide is selected as the organic dispersant, sodium hydroxide is selected as the basic catalyst, diethyltoluene diamine is selected as the amine curing agent, and nonylphenol polyoxygen is selected as the surfactant. Vinyl ether and carboxyl-terminated nitrile rubber are selected as the toughening agent. The specific operation steps are as follows:

[0023] (1) the synthesis process of boron novolac epoxy resin: 1) addition reaction: bisphenol A diglycidyl ether and formaldehyde are dissolved in n-butanol, mechanically stirred for 10min, then add the catalyst ammonia water that concentration is 28wt%, heat up The reaction was carried out at 80 °C for 2.5 h; after the rea...

Embodiment 2

[0047] The organic solvent is selected from toluene, the mol ratio of bisphenol A diglycidyl ether and formaldehyde is 1:1.0, the mass ratio of ammonia water and bisphenol A diglycidyl ether is 1:20; the mol ratio of boric acid and bisphenol A diglycidyl ether is 1:20. It is 1:2; n-butanol is selected as organic dispersant, potassium hydroxide is selected as basic catalyst, m-xylylenediamine is selected as amine curing agent, octylphenol polyoxyethylene ether is selected as surfactant, and carboxyl terminal is selected as toughening agent Nitrile rubber, the specific operation steps are as follows:

[0048] (1) Synthesis process of boron novolac epoxy resin: 1) Addition reaction: bisphenol A diglycidyl ether and formaldehyde are dissolved in toluene, mechanically stirred for 5min, then add the catalyst ammonia water with a concentration of 28wt%, be warming up to 90 ℃ reaction for 2h; after the reaction is completed, the temperature is cooled to 50 ℃, and the solution is disti...

Embodiment 3

[0057] The organic solvent selects xylene, the mol ratio of bisphenol A diglycidyl ether and formaldehyde is 1:1.5, the mass ratio of ammonia water and bisphenol A diglycidyl ether is 1:100; the mol of boric acid and bisphenol A diglycidyl ether is 1:100; The ratio is 1:10; the organic dispersant is selected from toluene, the basic catalyst is selected from barium hydroxide, the amine curing agent is selected from diaminodiphenylmethane, the surfactant is selected from sorbitan ester, and the toughening agent is selected from epoxy nitrile rubber , the specific operation steps are as follows:

[0058] (1) Synthesis process of boron novolac epoxy resin: 1) Addition reaction: dissolving bisphenol A diglycidyl ether and formaldehyde in xylene, mechanically stirring for 10min, then adding catalyst ammonia water with a concentration of 28wt%, warming up to Reaction at 85°C for 3h; after the reaction was completed, the temperature was cooled to 55°C, and the solution was distilled u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com