Hall thruster with novel buffer cavity

A technology of Hall thruster and buffer cavity, which is applied in the direction of thrust reverser, machine/engine, and utilization of plasma, which can solve the problems of low gas density and homogenization degree, and achieve the problem of alleviating the problem of gas unevenness and high magnetic energy. The effect of accumulation and homogenization is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

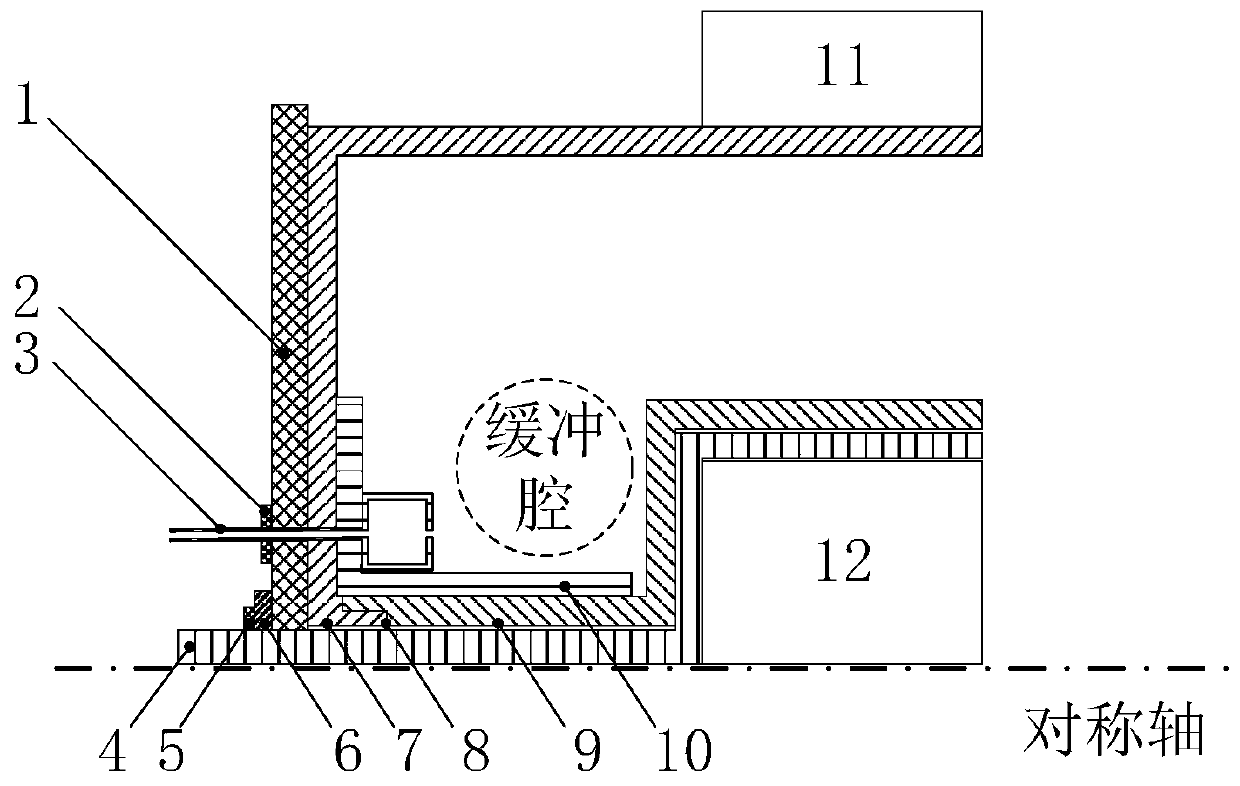

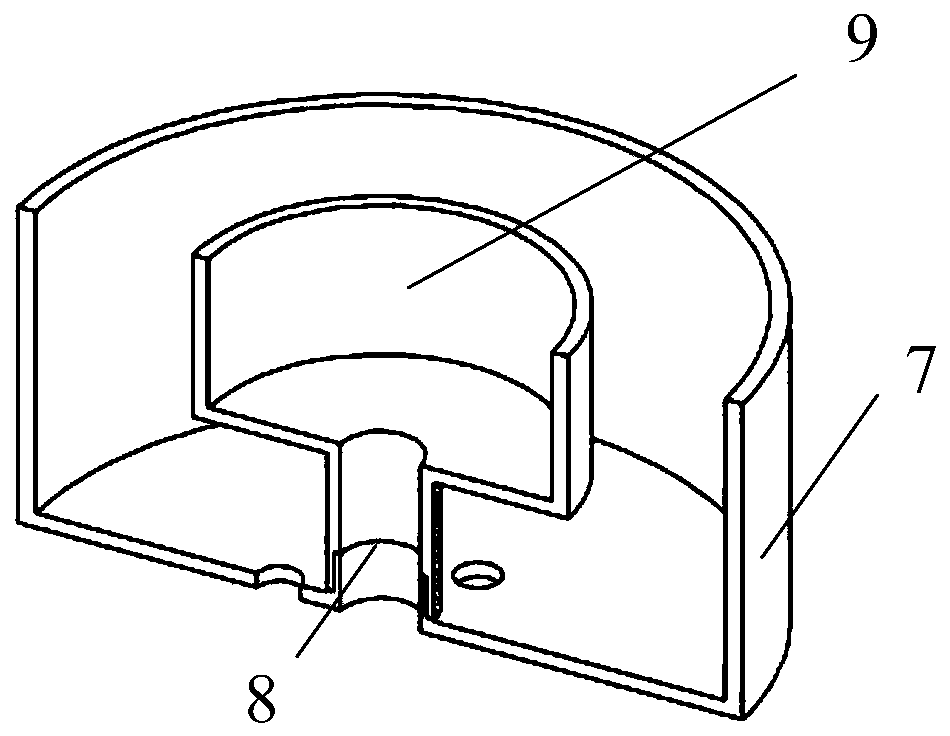

[0018] combined with Figure 1 to Figure 2 Describe the specific embodiment of the present invention: the present invention is a Hall thruster with a novel buffer cavity, such as figure 1 As shown, it includes bottom plate 1, nut 2, gas distributor 3, permanent magnet support 4, fixing nut 5, outer ceramic screen 7, inner ceramic screen 9, anode 10, outer permanent magnet 11 and inner permanent magnet 12; outer ceramic screen 7 and the inner ceramic screen 9 are cylindrical structures nested inside and outside, and there are radial gaps and axial gaps between the outer ceramic screen 7 and the inner ceramic screen 9, forming a buffer cavity between the outer ceramic screen 7 and the inner ceramic screen 9. Structure; the anode 10 and the inner ceramic screen 9 are fixedly installed on the base plate 1 through the gas distributor 3 and the nut 2; the inner permanent magnet 12 is fixedly installed in the outer ceramic screen 7 through the permanent magnet bracket 4, and the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com