Method for liquefying a hydrocarbon-rich flow

A hydrocarbon flow and mixed refrigerant technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of high cost and high equipment, and achieve the effect of low unit energy consumption and compact equipment or process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

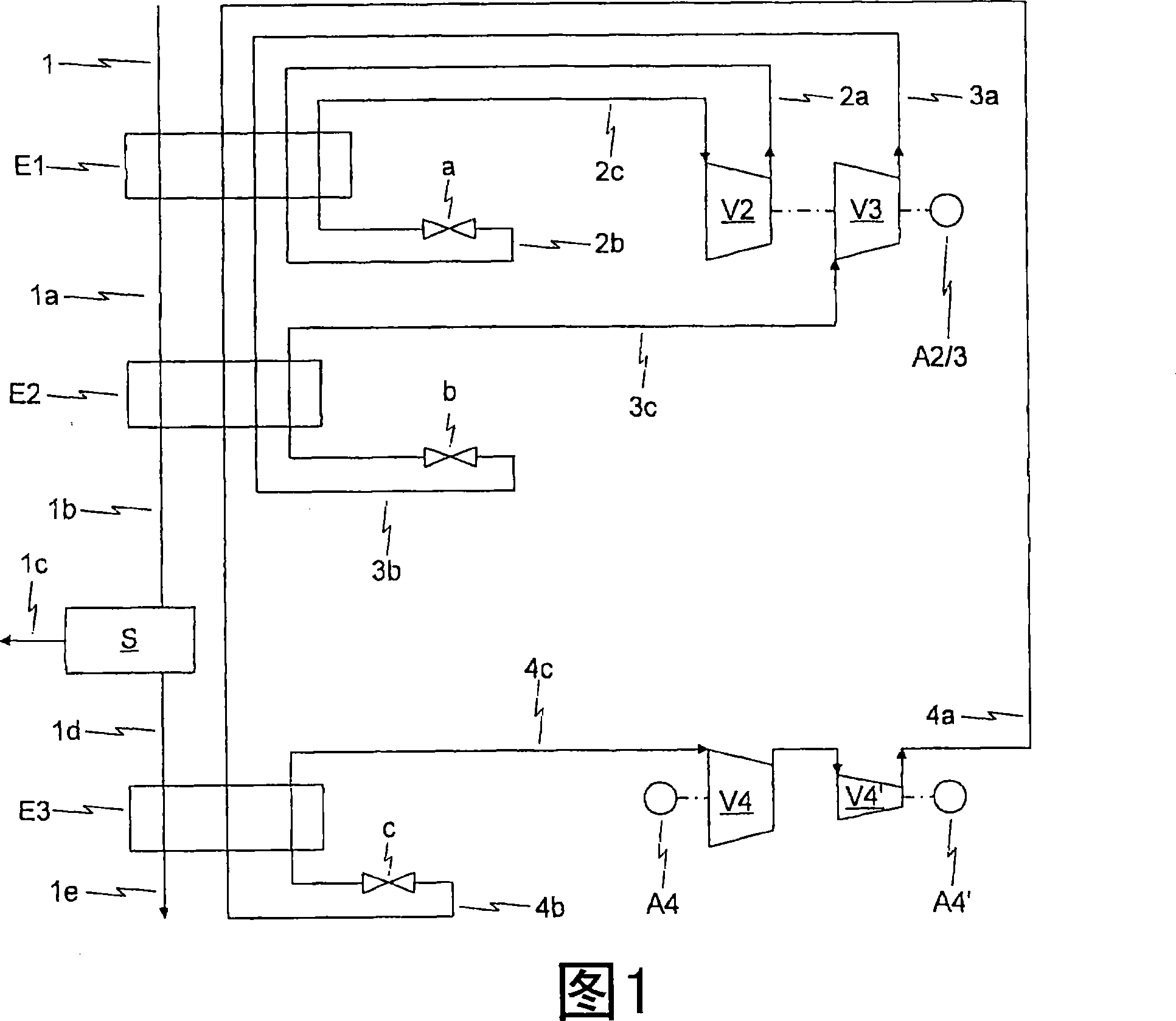

[0025] The hydrocarbon-rich stream to be liquefied is cooled in heat exchanger E1 against the vaporized mixed refrigerant stream 2b of the first mixture cycle 2a-2c. Next, the hydrocarbon-rich stream is sent through line 1a to heat exchanger E2 and in this heat exchanger is further cooled against the evaporated mixed refrigerant stream 3b of the second mixture cycle 3a-3c.

[0026] At the outlet of heat exchanger E2, the temperature of the cooled hydrocarbon-rich stream is -30°C to -70°C, preferably -40°C to -60°C. It is now conveyed via line 1b to a separation unit S, shown only as a black box.

[0027] In this separation unit S the above-mentioned C 3+ Separation, in which the components separated from the hydrocarbon-rich stream to be liquefied are discharged from the separation unit S through line 1c.

[0028] The hydrocarbon-rich stream to be liquefied is then sent via line 1d to the third heat exchanger E3 and is liquefied and subcooled in this heat exchanger against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com