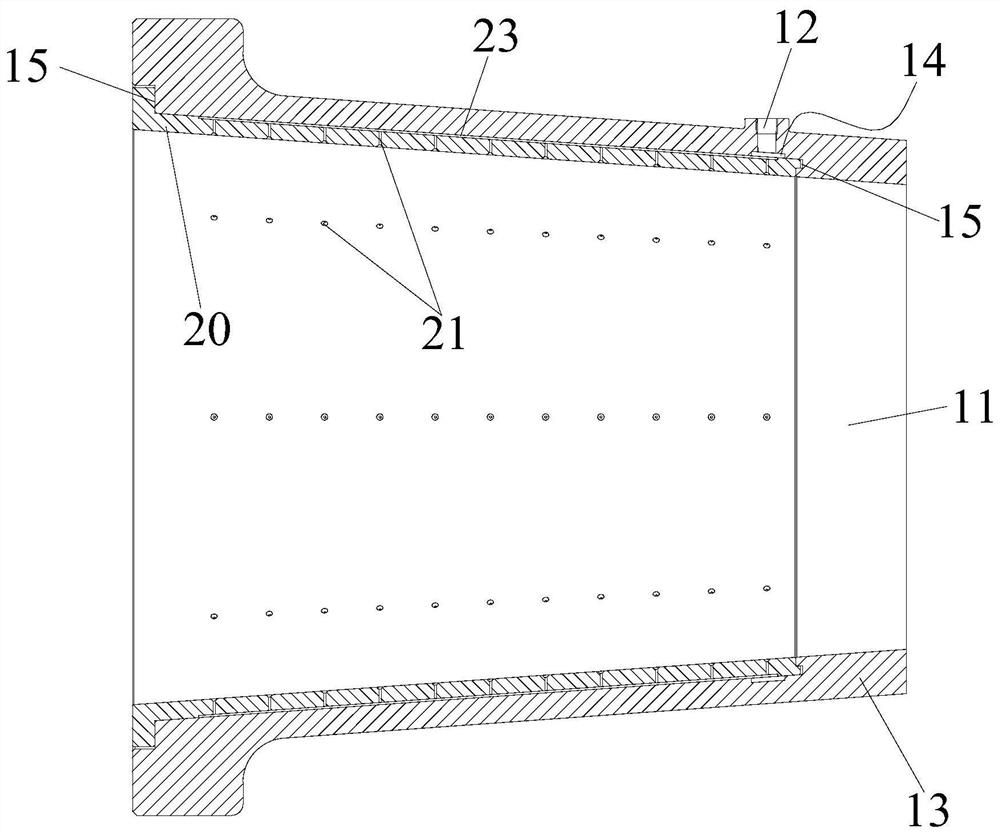

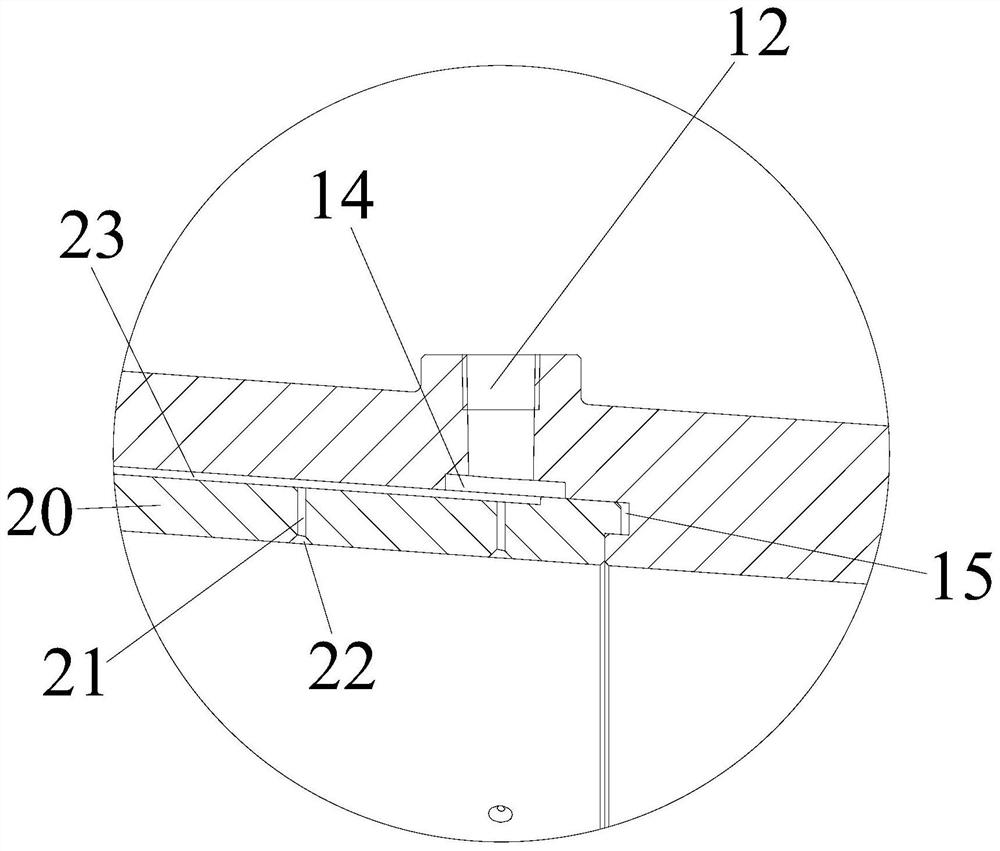

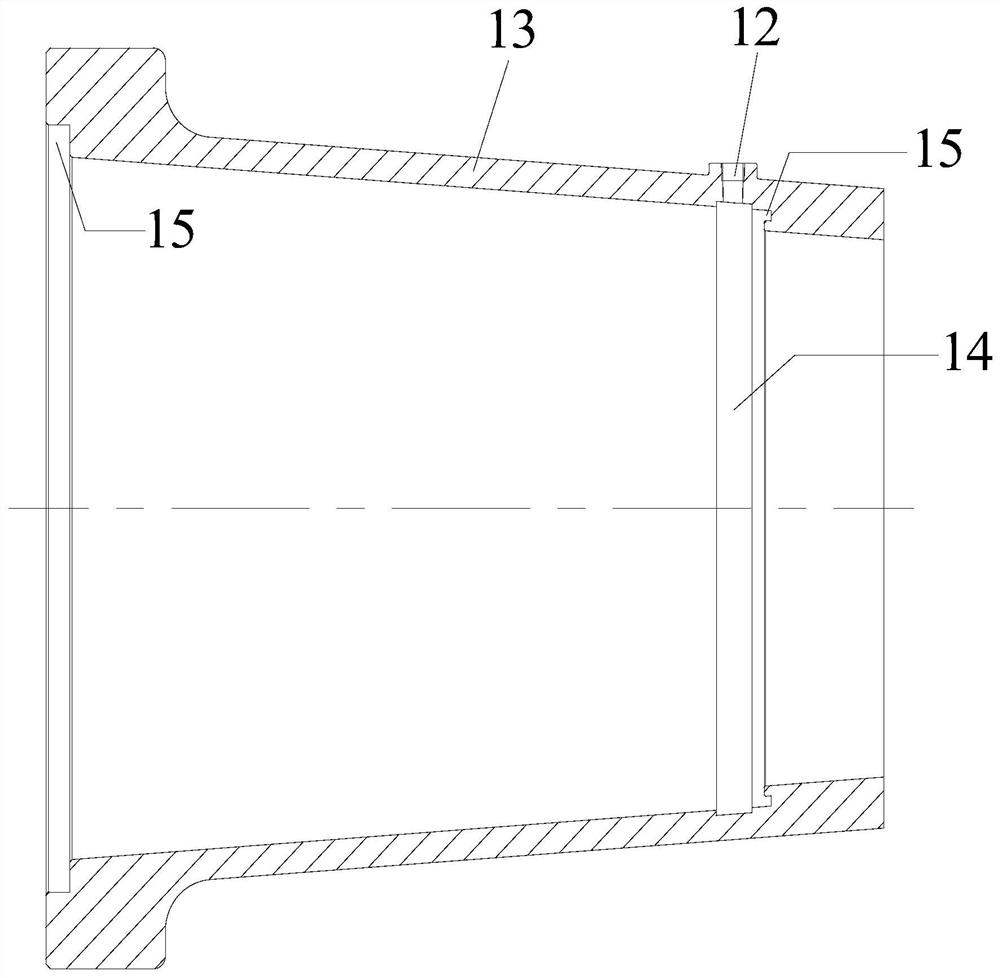

Volute and compressor

A compressor and volute technology, applied in the field of compressors, can solve the problems of large volume of the compressor volute, high exhaust temperature, excessive vibration, etc., and achieve the effects of avoiding thermal deformation gaps, ensuring mechanical performance, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0025] Heat pump technology is recognized at home and abroad as a method that can effectively recover waste heat. The heat pump working medium is used to evaporate and absorb heat in the evaporator to recover industrial waste heat. After the evaporated steam is compressed by the compressor to raise the temperature and boost the pressure, its energy grade is improved. And condensed in the condenser, the released heat can be used for industrial heating, etc., and the condensed liquid working medium is returned to the evaporator through the throttle valve to complete the cycle.

[0026] There is a large amount of waste heat at 80-90°C in the industrial field, and there is also a demand for heat sources at 120-130°C. Water or steam (R718) is used as a natural working medium, and its ODP and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com