Vortex mechanical single-disc double-stage molded line structure design method

A structural design and mechanical technology, which is applied in the field of single-disc and double-stage structure design of scroll machinery, can solve problems that affect the service life and reliability of the machine, excessive expansion of the scroll due to heating, etc., so as to improve service life and reliability and reduce power consumption. Consumption, reduce the effect of exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments will be described in detail below in conjunction with the accompanying drawings.

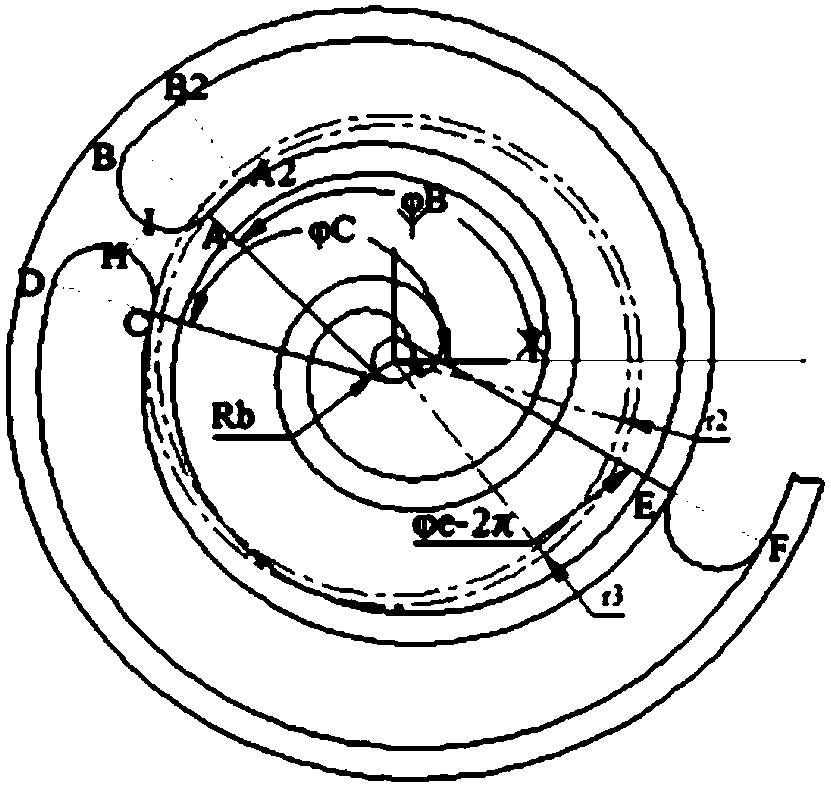

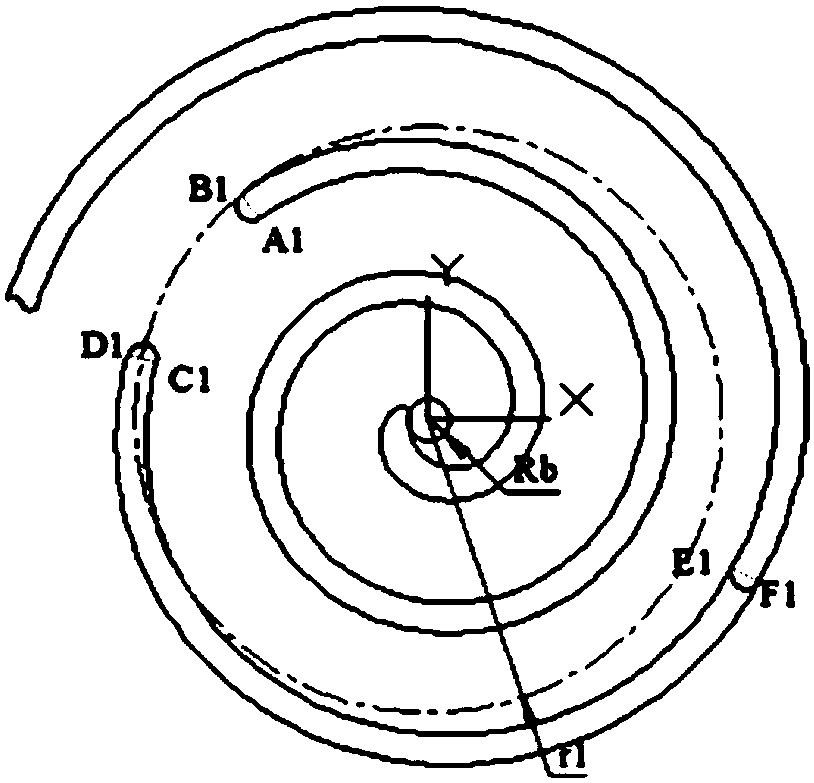

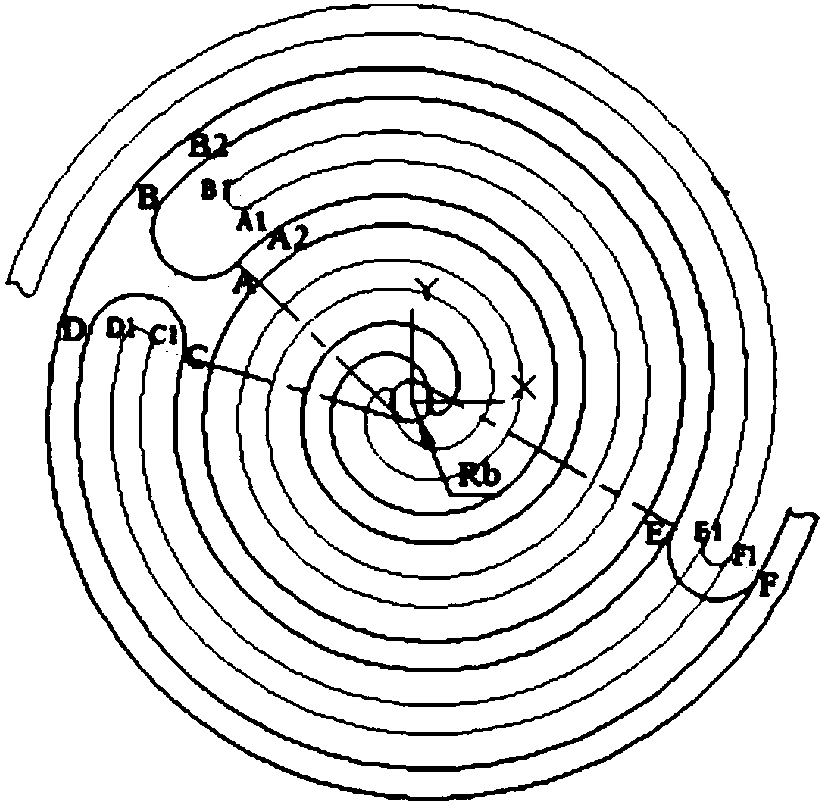

[0046] See attached figure 1 to attach Figure 4, a single-disk double-stage structure design method for a scroll machine, including a movable scroll modified profile and a fixed scroll modified profile, the movable scroll modified profile is composed of circular involute scroll tooth cut-offs, the The fixed scroll correction profile is composed of adjacent circular involute scroll teeth, including the following steps:

[0047] Step 1: Modification of the profile line of the fixed scroll;

[0048] Make a circle r 2 It intersects the outer spiral of the fixed scroll at point A, at point A the perpendicular to the outer spiral of the fixed scroll intersects at point B through the inner spiral of the fixed scroll, and passes through points A and B to make arc AB, arc AB It is the helical correction for the two-stage compression inlet end of the fixed scroll; similarly, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com