Sulfur removal method of anhydrous hydrofluoric acid

A technology of anhydrous hydrofluoric acid and sulfuric acid, applied in hydrogen fluoride, fluorine/hydrogen fluoride, etc., can solve the problems of increasing maintenance costs, reducing enterprise benefits, and hidden dangers in production, and achieving the effects of reducing impurities, increasing cleanliness, and increasing gas density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

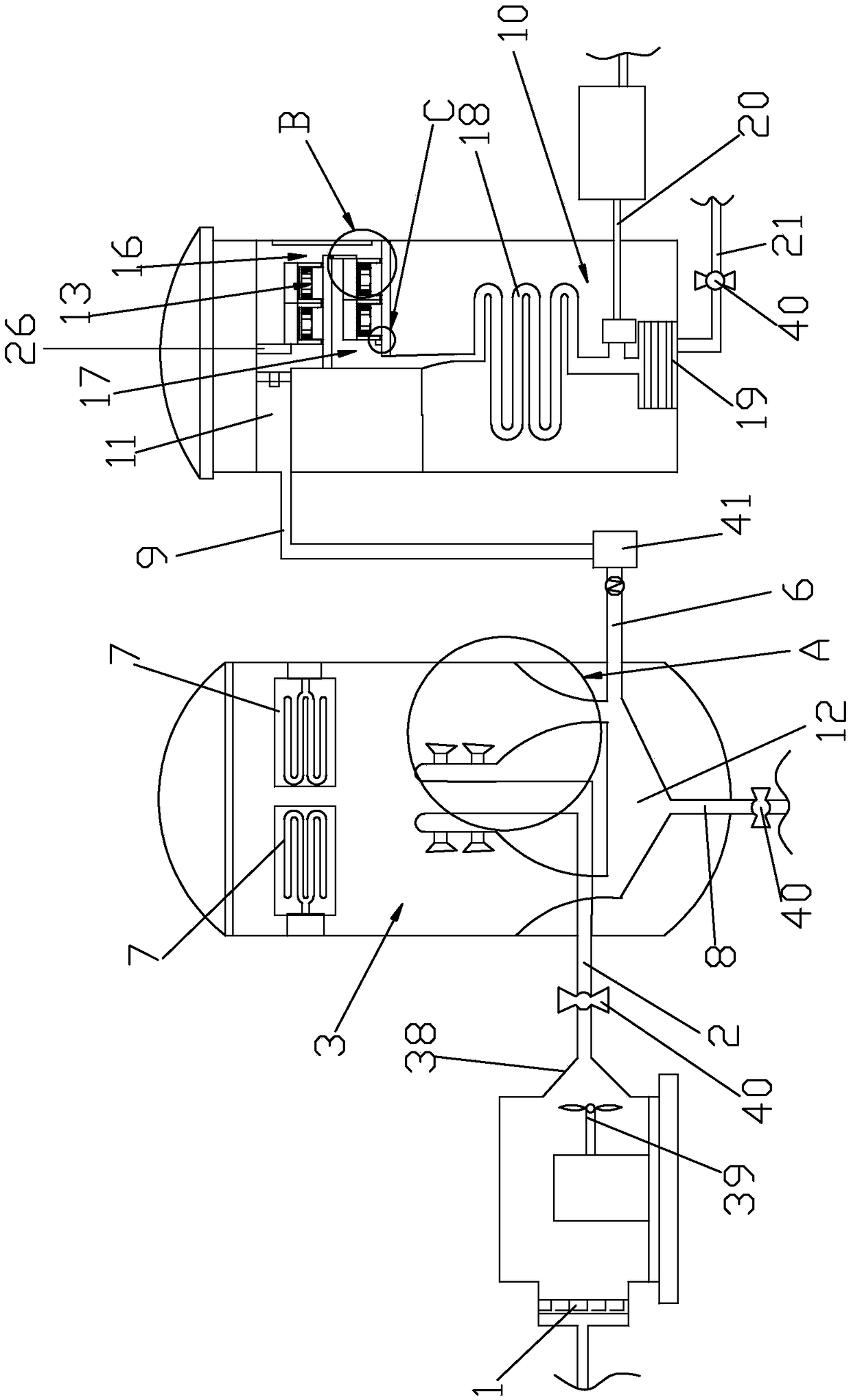

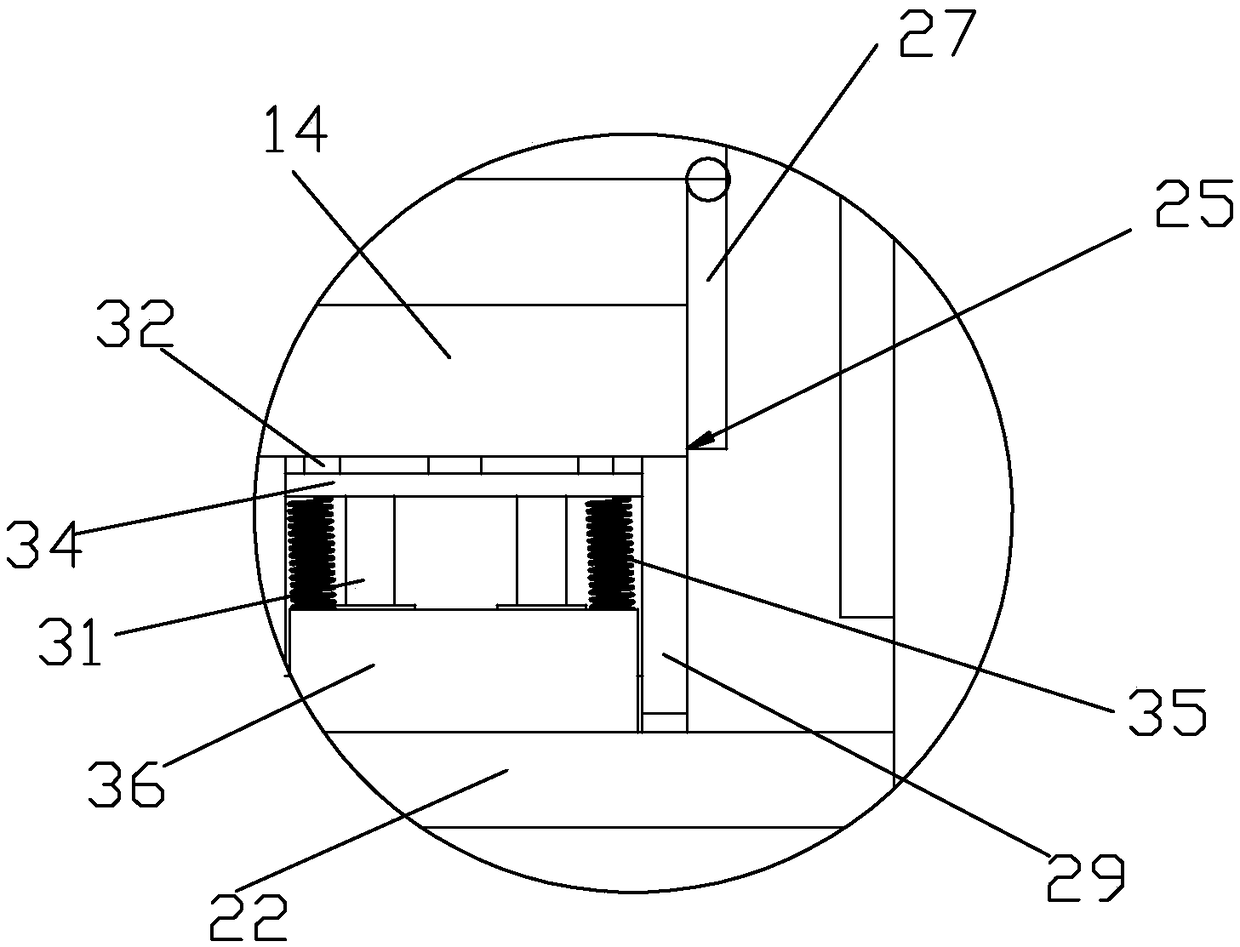

[0043] Such as Figure 1 to Figure 5 Shown, be the sulfur removal method of a kind of anhydrous hydrofluoric acid of the present invention, comprise the steps:

[0044] 1) Preparation of hydrofluoric acid gas

[0045] a. Wash the fluorite with water, wash away the sundries on the surface, and after drying, use a vibrator to evenly add it to the pulverizer and crush it into powder;

[0046]b. Put the pulverized fluorite powder and sulfuric acid into the reaction furnace, the concentration of sulfuric acid is 98%, heat, and react to obtain crude hydrogen fluoride gas;

[0047] 2) Dust removal of gas

[0048] a, the crude hydrogen fluoride gas is passed to the filter screen 1, and the gas passes through the filter screen 1 and is blown to the first air intake pipe 2 by the rotating fan 39;

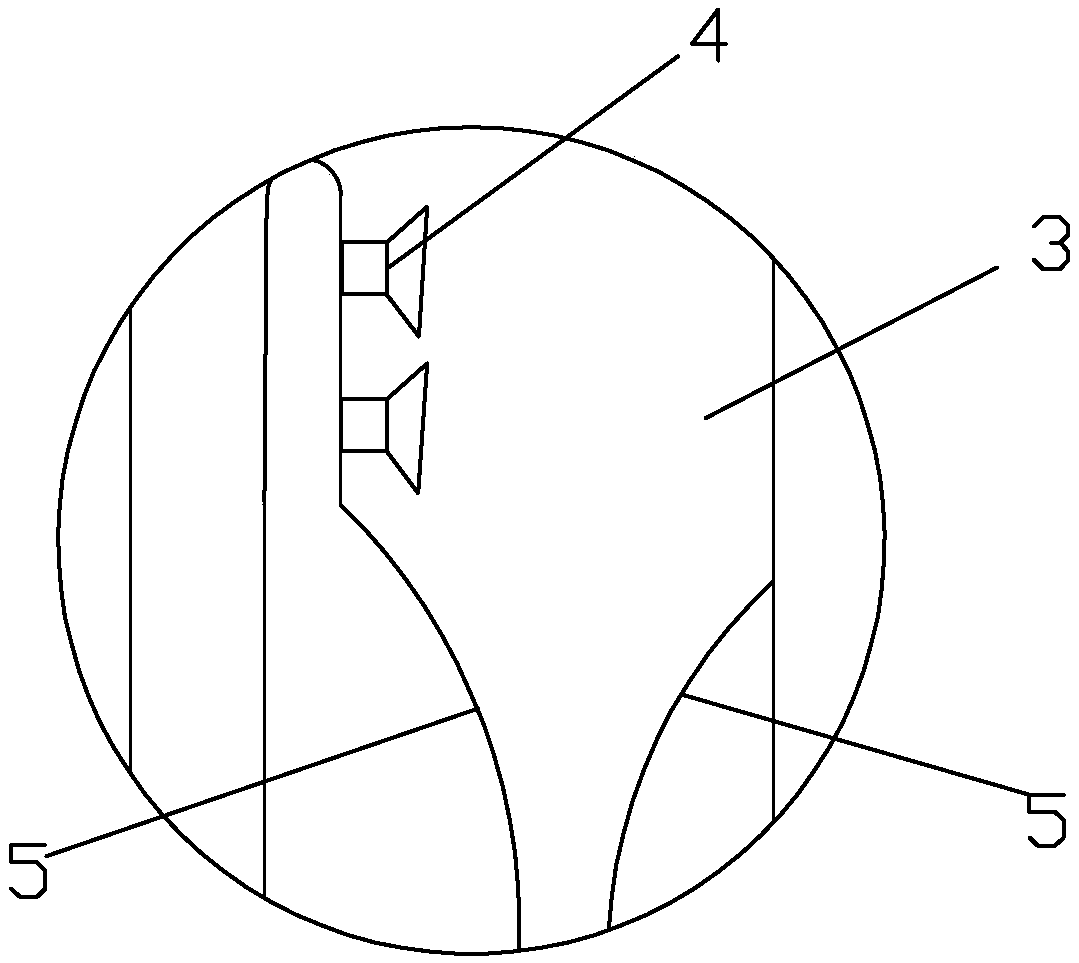

[0049] b. Crude hydrogen fluoride gas enters the dust washing tower 3 through the first air inlet pipe 2, heats the heating tank plate 7 in the dust washing tower 3, increases the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com