Jet solder vessel

A spray soldering and soldering technology, which is applied in the field of spray solder bath, can solve problems such as poor soldering, unstable oxygen concentration on the solder surface, and inability to suppress sharpening, so as to ensure wettability, reduce oxygen concentration, and suppress pull sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

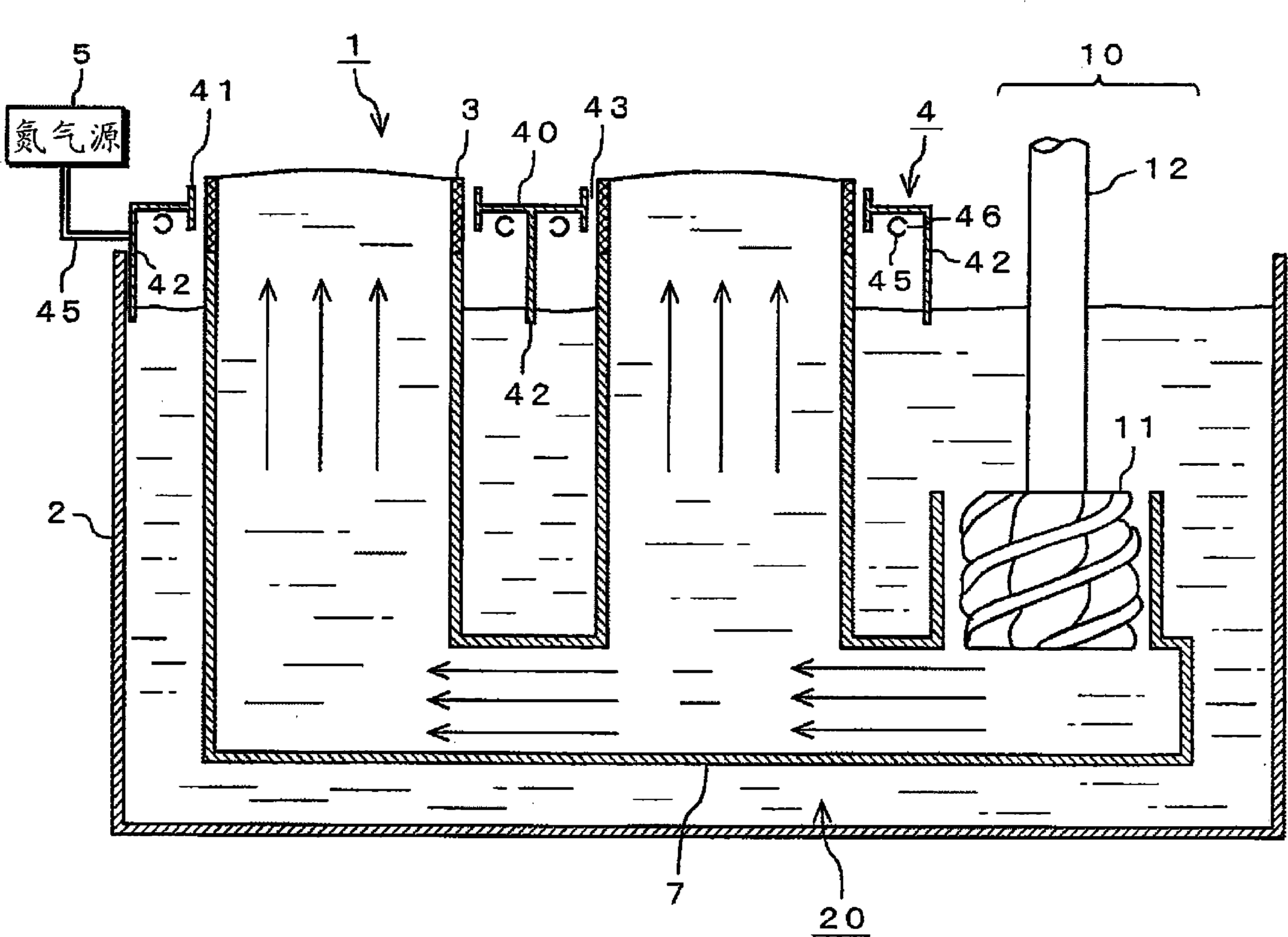

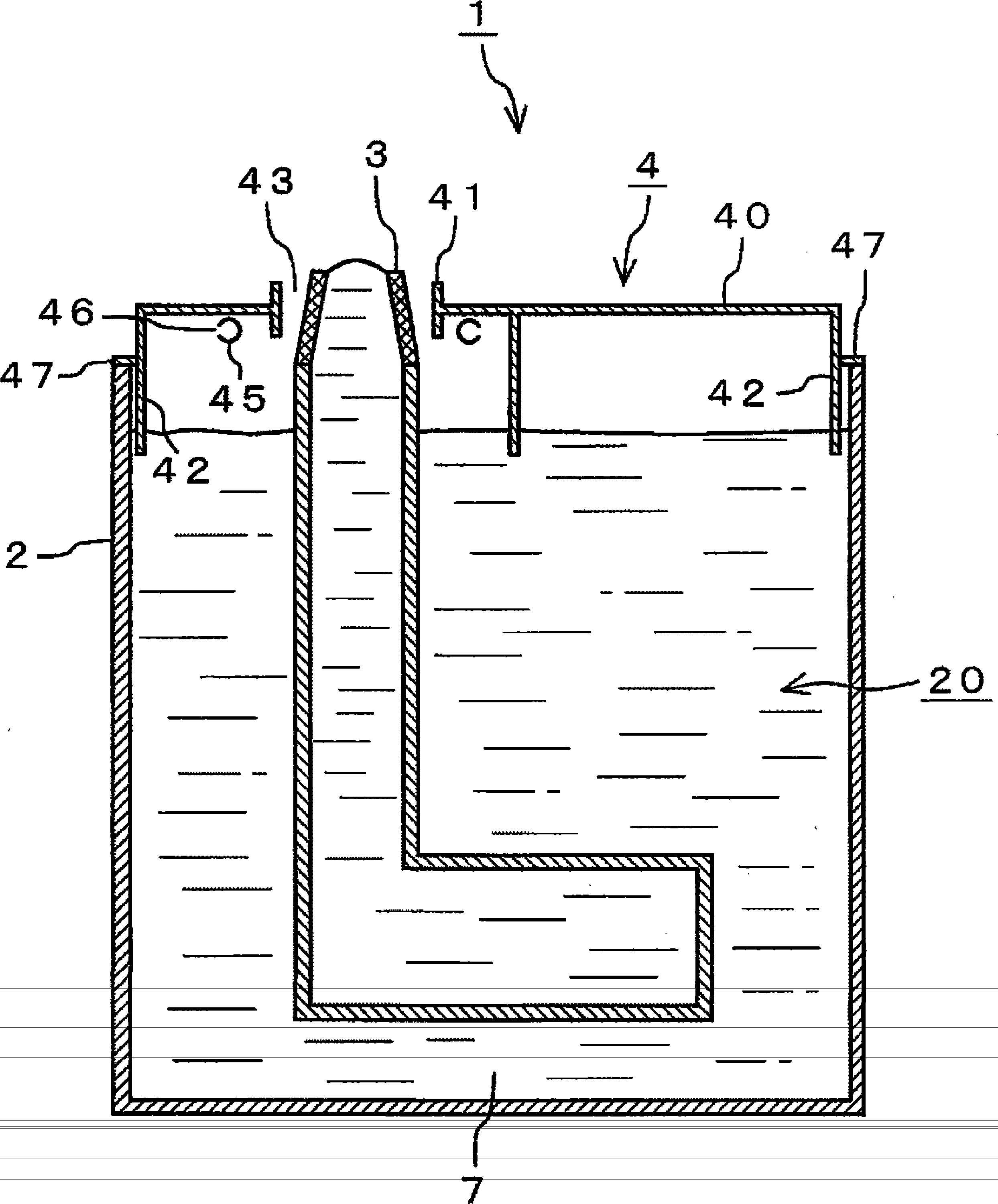

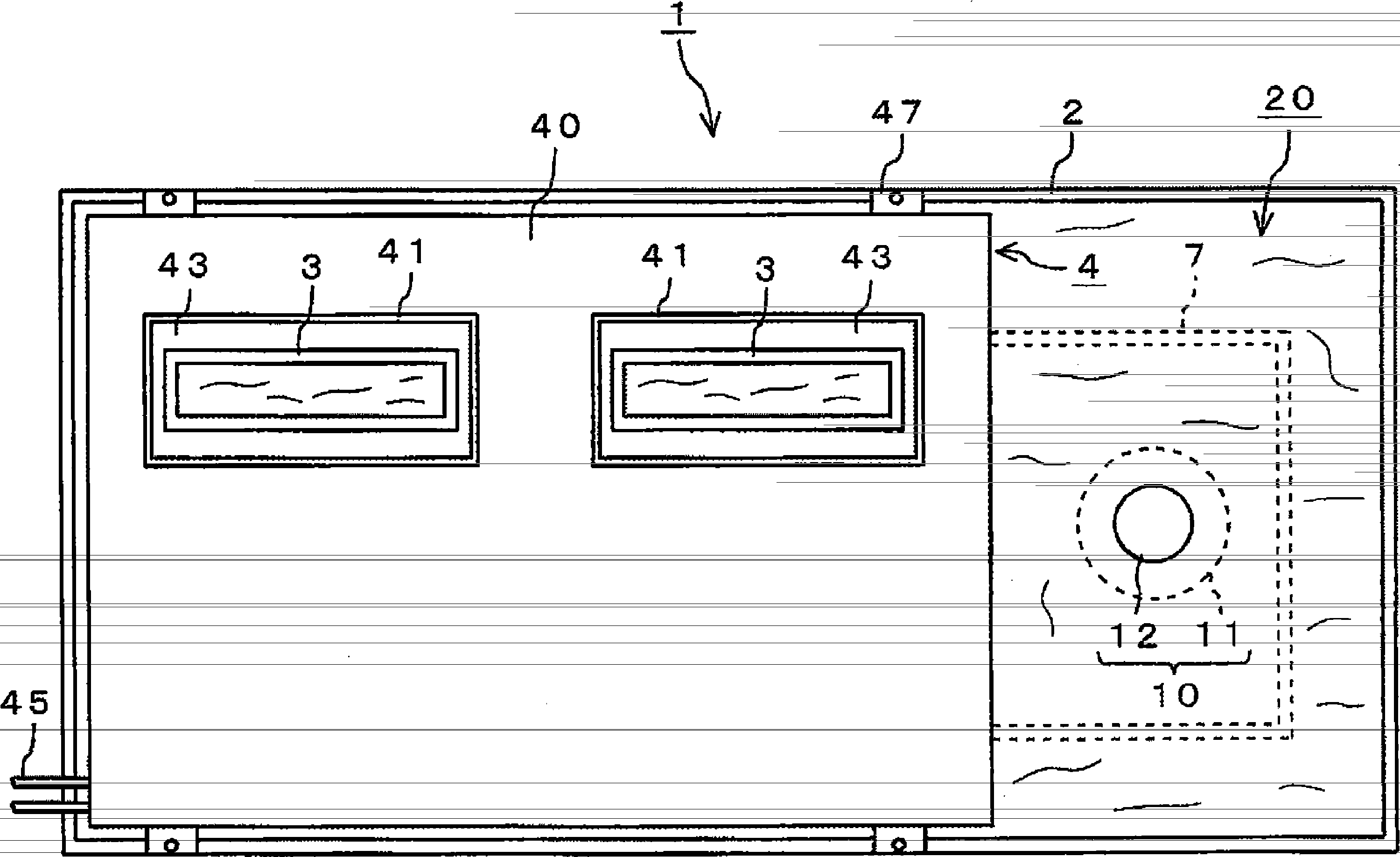

[0023] Such as Figure 1~3 As shown, the jet flow solder tank 1 of the present embodiment is composed of a solder storage unit 2 , a nozzle unit 3 , a duct unit 7 , a pump unit 10 , and a supply device 4 .

[0024] Solder 20 is housed in the solder container 2 . The solder 20 is, for example, lead-free solder and is composed of Sn—Ag—Cu, Sn—Zn—Bi, or the like. The pump part 10, the duct part 7, and the nozzle part 3 which are injection means are provided in the solder storage part 2. As shown in FIG. The jet solder bath 1 uses a pump unit 10 to spray the solder 20 contained in the solder storage unit 2 through the duct unit 7 and from the nozzle unit 3 onto a printed circuit board (not shown).

[0025] The pump unit 10 has a motor, an impeller 11 and a shaft 12 (not shown). When the motor is driven, the shaft 12 rotates the impeller 11 to spray the solder 20 melted by a heater (not shown), and the solder 20 flows into the duct portion 7 in a predetermined flow direction. T...

no. 2 Embodiment approach

[0042] In this embodiment, the supply device 4A in which supply ports are arranged at uneven intervals will be described. Since members with the same names and reference numerals as those in the above-described embodiments and examples have the same functions, description thereof will be omitted.

[0043] Such as Image 6 As shown, the supply device 4A includes a cover body portion 40 and a supply tube 45A. The supply pipe 45A is provided to surround the opening 43 . Supply ports 46A, 47A, 48A, and 49A are provided in the supply pipe 45A. The supply ports 46A, 47A, 48A, and 49A are formed on the side wall 42 for supplying nitrogen gas toward the side wall 42 .

[0044] The supply ports 46A are arranged at the same interval as the interval between the supply ports 46 described in the above embodiment. The size of the supply port 46A is the same as that of the supply port 46 . The supply ports 47A are arranged such that the interval between the supply ports 47A is smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com