Coil pipe type coal pyrolysis device

A coal pyrolysis, coil-type technology, used in special forms of dry distillation, indirect heating dry distillation, petroleum industry, etc., can solve problems such as poor heat exchange effect, achieve high gas density, high transportation efficiency, and reduce heat exchange area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

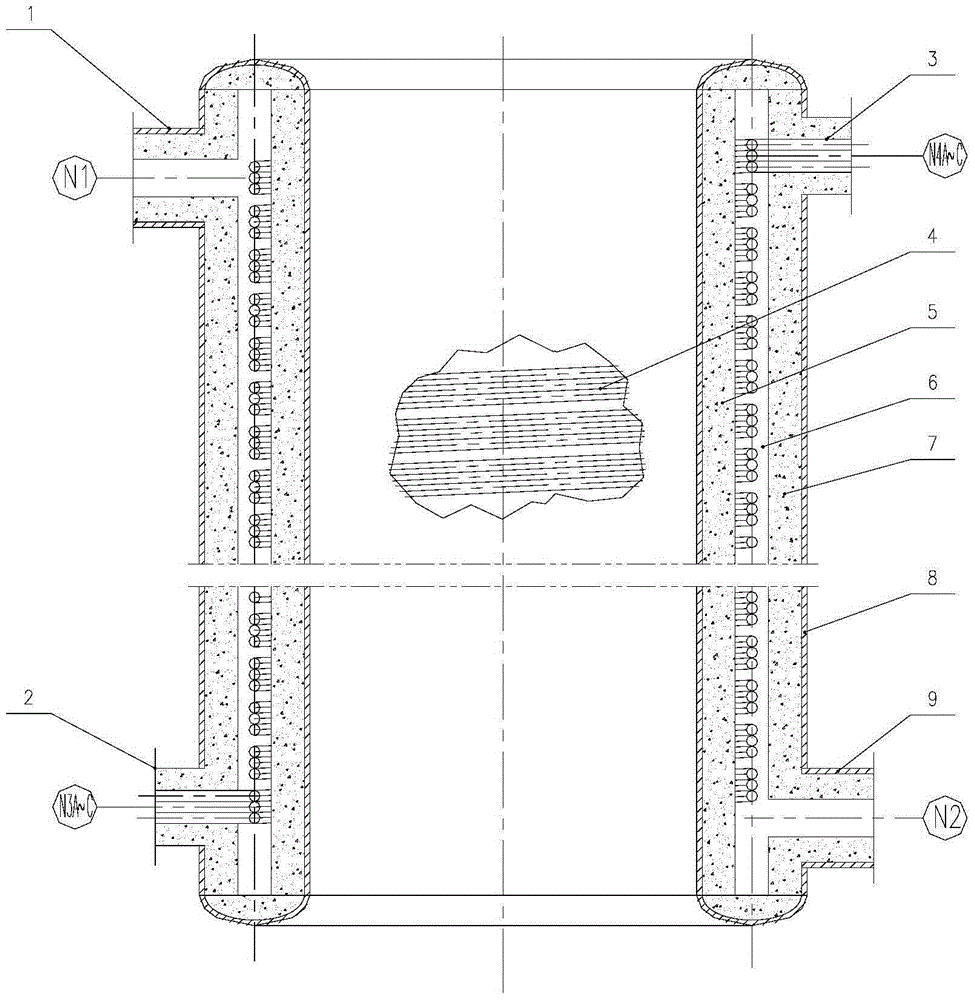

[0024] Attached below figure 1 The present invention is further described in detail, and the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0025] Such as figure 1 As shown, the coil type coal pyrolysis device proposed by the present invention includes: flue gas inlet 1, coil inlet 2, coil outlet 3, heat exchange coil group 4, inner insulation layer 5, annular narrow cavity 6, outer The heat insulation layer 7, the shell 8, the flue gas outlet 9, the inner heat insulation layer 5 and the outer heat insulation layer 7 form an annular narrow cavity 6, and the heat exchange coil group 4 is placed in the annular narrow cavity 6, and the heat exchange coil group 4 It is composed of 3 sets of heat exchange coils. The radius of gyration of the heat exchange coils around the center line of the coal pyrolysis device is 80 times the inner diameter of the heat exchange coil tubes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com