A flexible flat cable automatic slitting equipment

A flexible flat cable and slitting technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as low production efficiency, process bottlenecks, poor process, etc., to eliminate poor insulation, reduce gold plating costs, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

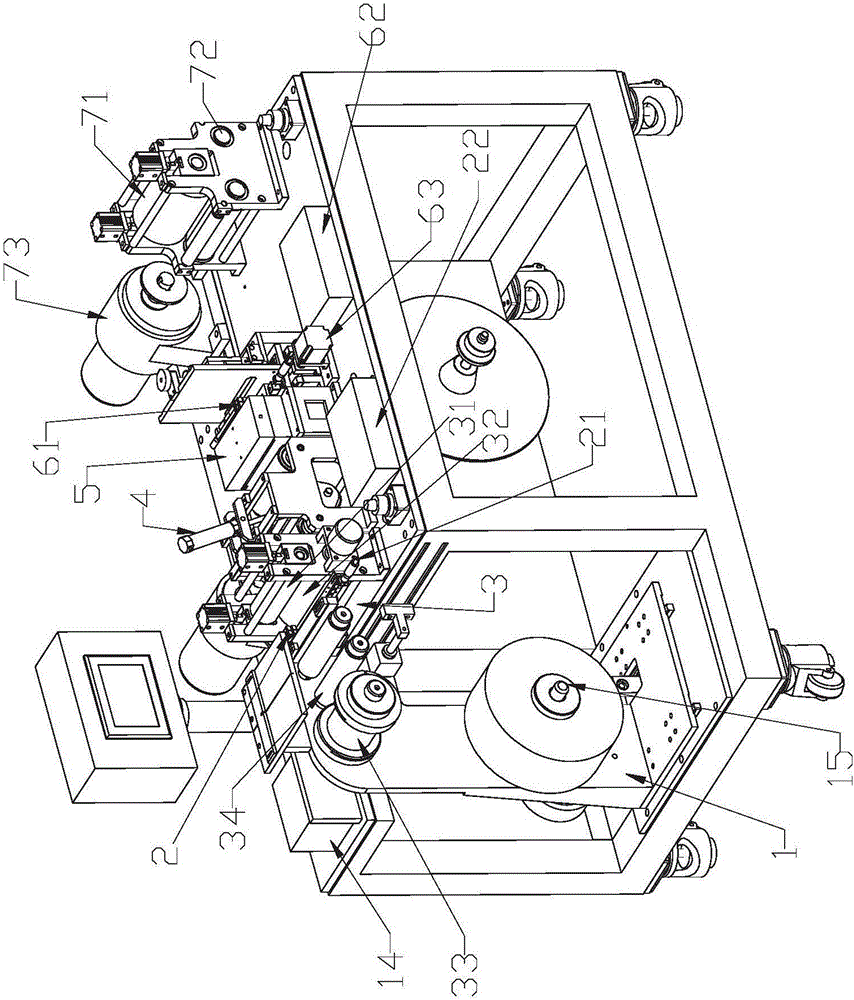

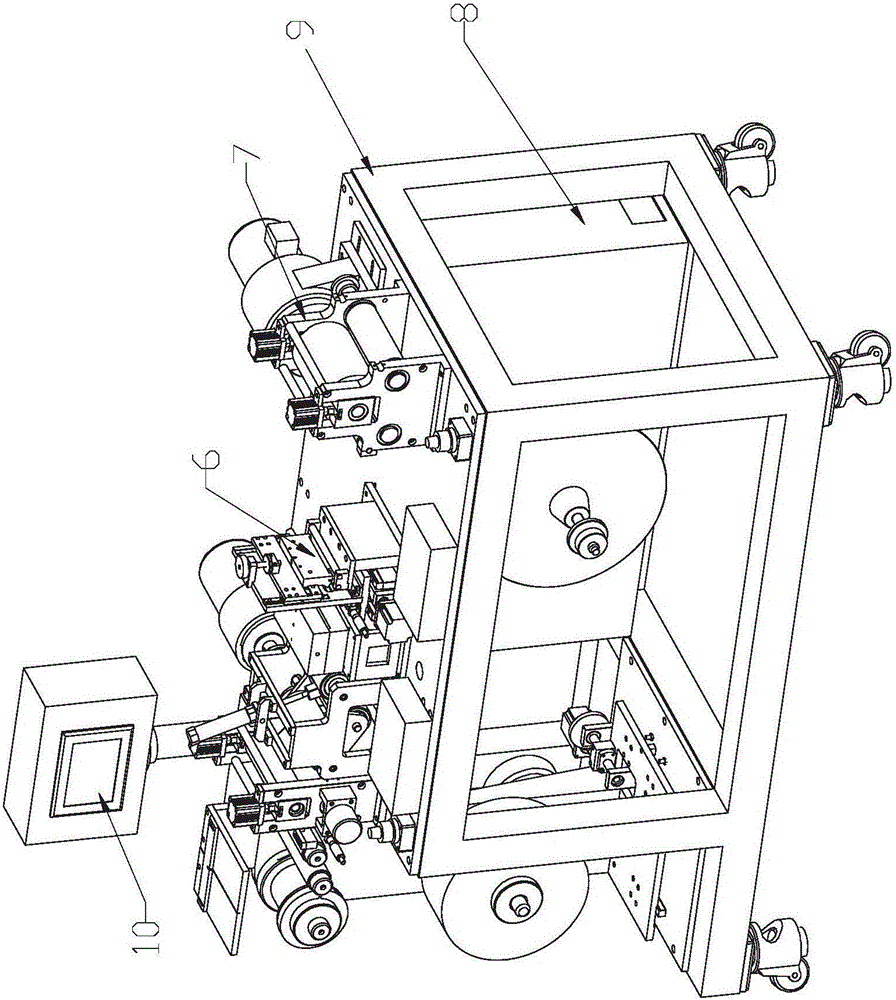

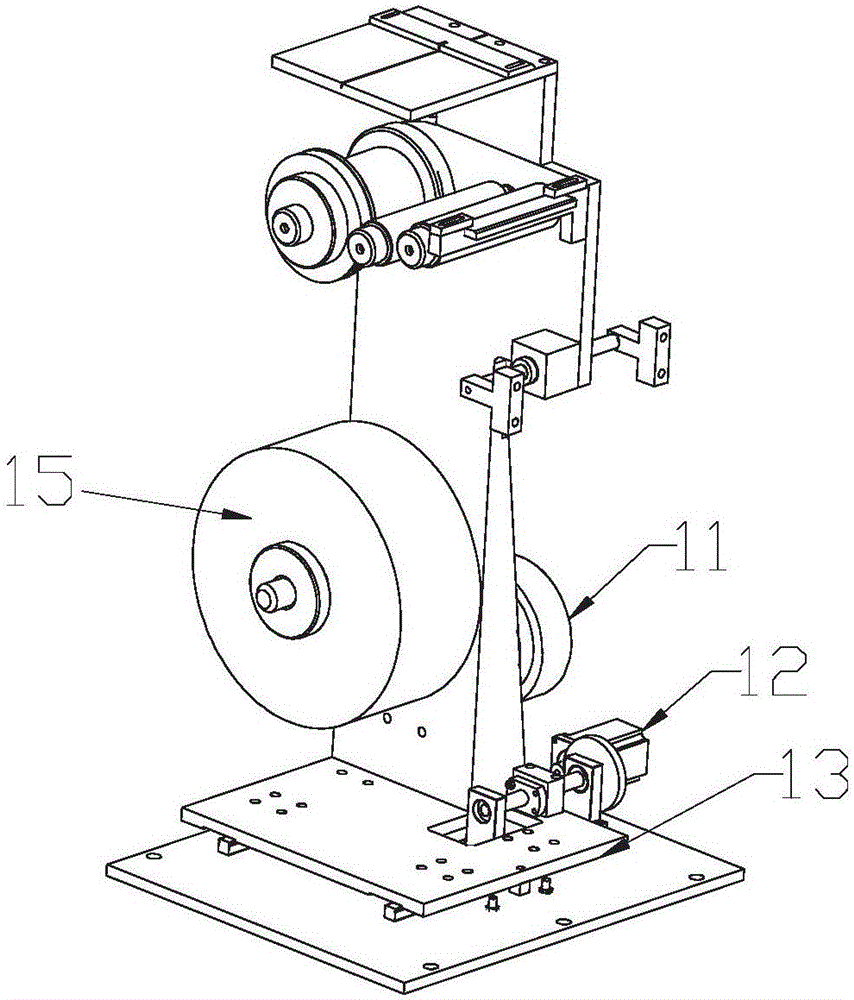

[0024] Such as figure 1 and figure 2 As shown, it is a structural schematic diagram of the flexible flat cable automatic slitting device of the present invention, including: a feeding mechanism 1, a material belt deviation correction sensor 2, a feeding mechanism 3, a flexible flat cable tension mechanism 4, a heating and blowing mechanism 5, and a slitting mechanism. Mechanism 6, lead-out machine mechanism 7 and edge material receiving mechanism 8, the material discharging mechanism 1, the material belt deviation correction sensor 2, the feeding mechanism 3, the flexible flat cable tension mechanism 4, the heating and blowing mechanism 5, the slitting mechanism 6, The lead-out machine mechanism 7 and the edge material receiving mechanism 8 are arranged on a workbench 9, and the described discharge mechanism 1 is arranged on one end of the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com