A cold heading opening and closing mold for special-shaped parts with double flanges for automobiles

A technology of opening and closing molds and double flanges, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., which can solve the problems of increased production costs and reduced processing efficiency, and achieve improved work efficiency , reduce production costs, and solve the effect of process bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

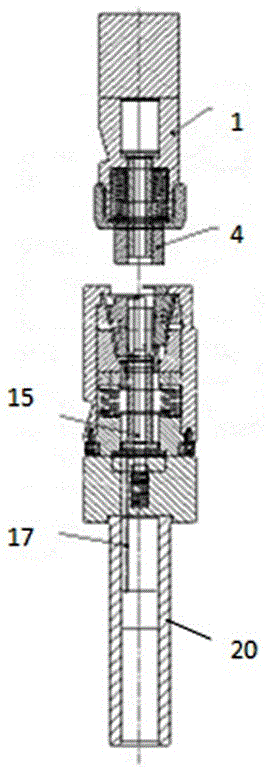

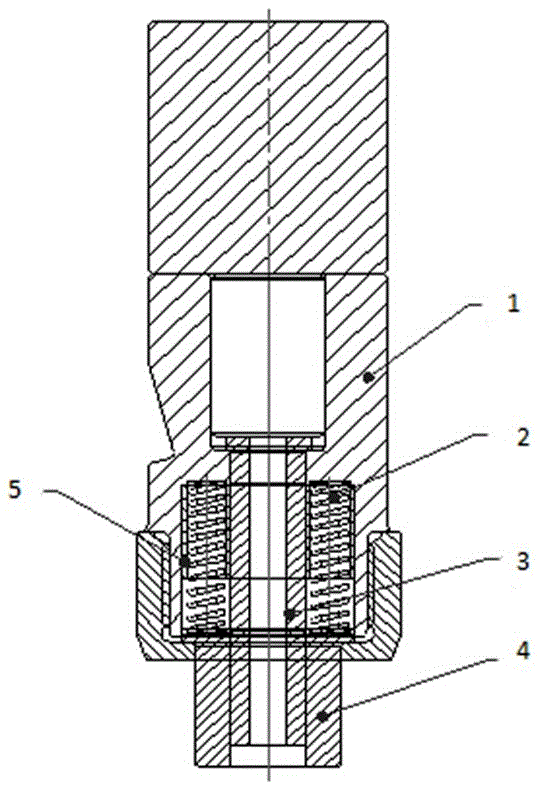

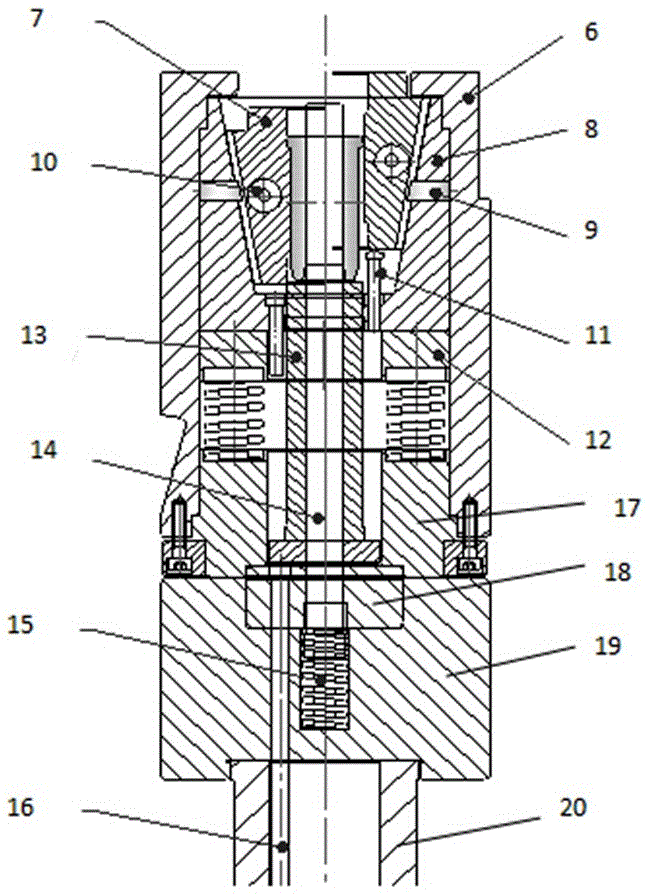

[0025] like figure 1 , figure 2 , image 3 As shown, a cold heading opening and closing mold for double-flange special-shaped parts of an automobile includes a punch part and a molding part, and the punch part includes a punch shell 1, a punch spring 2, a punch push tube 3, a punch A punch 4 and a spring sleeve 5 are provided, and an upper "convex" groove is provided in the punch shell 1. The punch push tube 3 is fixedly installed in the small head of the upper "convex" groove of the punch shell 1. The outer side of the punch push tube 3 and the big head of the upper "convex" groove is provided with a spring sleeve 5, the spring sleeve 5 is provided with a punch spring 2, and one end of the punch spring 2 is connected with a punch With a punch 4, the bottom diameter of the punch 4 is larger than the width of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com