Integrated furnace charge pellet pneumatic packing and reducing slag pneumatic raking machine for magnesium metal reduction tank

A metal magnesium and integrated machine technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of inability to realize long-distance slag removal, increase the crushing rate of charge pellets, and reduce the output rate of metal magnesium. To achieve the effect of reducing the investment of tools before the furnace, prolonging the life and improving the output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1——Single reduction tank charge pellet Pneumatic filling operation

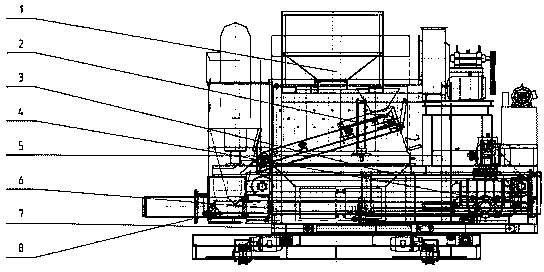

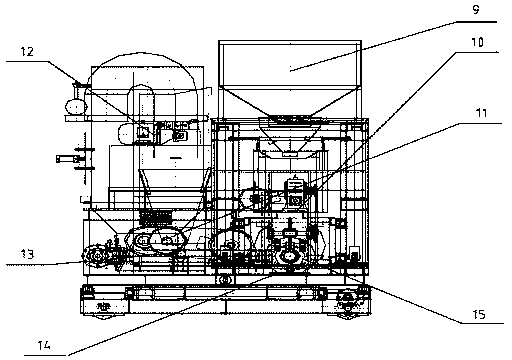

[0019] When working on a single reduction tank, the lateral travel device (6) controlled by the hydraulic cylinder moves forward to the position of the reduction tank mouth, the main transmission mechanism (3-1) stops automatically after running in place, and the main transmission mechanism (3-1) runs Enter the reduction tank, start the Roots blower (4) and the corner belt conveyor (5) at this time, and start charging. The Roots blower (4) then runs the main transmission mechanism (3-1) and automatically shuts down after falling back into place.

Embodiment 2

[0020] Example 2 - for Reduction tanks with different arrangement heights Perform pneumatic filling operations

[0021] When working on reduction tanks with different arrangement heights, the fuselage (3) is lifted in the vertical direction by the action of the fuselage lifting mechanism (2) controlled by the hydraulic cylinder, and the fuselage (3) is aligned with the recovery tank to be removed. Then perform the above actions after the position of the center line of the machine.

Embodiment 3

[0022] Embodiment 3——Single reduction tank Scrapping operation

[0023] When working on a single reduction tank, the lateral travel device (6) controlled by the hydraulic cylinder moves forward to the position of the reduction tank mouth, the Roots blower (4) is started, and the main transmission mechanism (3-1 ) into the reduction tank, the reduction slag is discharged from the equipment through the air supply pipeline (8) in the main transmission mechanism (3-1), and the dust enters the dust collector (1) for processing; at this time, the Roots blower (4 ), the main transmission mechanism (3-1) stops automatically after running in place, and the running transverse travel device (6) retreats in place and stops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com