Technique for extracting L-tryptophan in fermentation liquor

An extraction process and tryptophan technology, applied in the field of bioengineering, can solve the problems of high pressure of secondary concentration equipment, slow plate and frame filtration, and high pressure of vacuum film concentration, so as to ensure product quality and content, and process environmental pollution. Small, product throughput reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

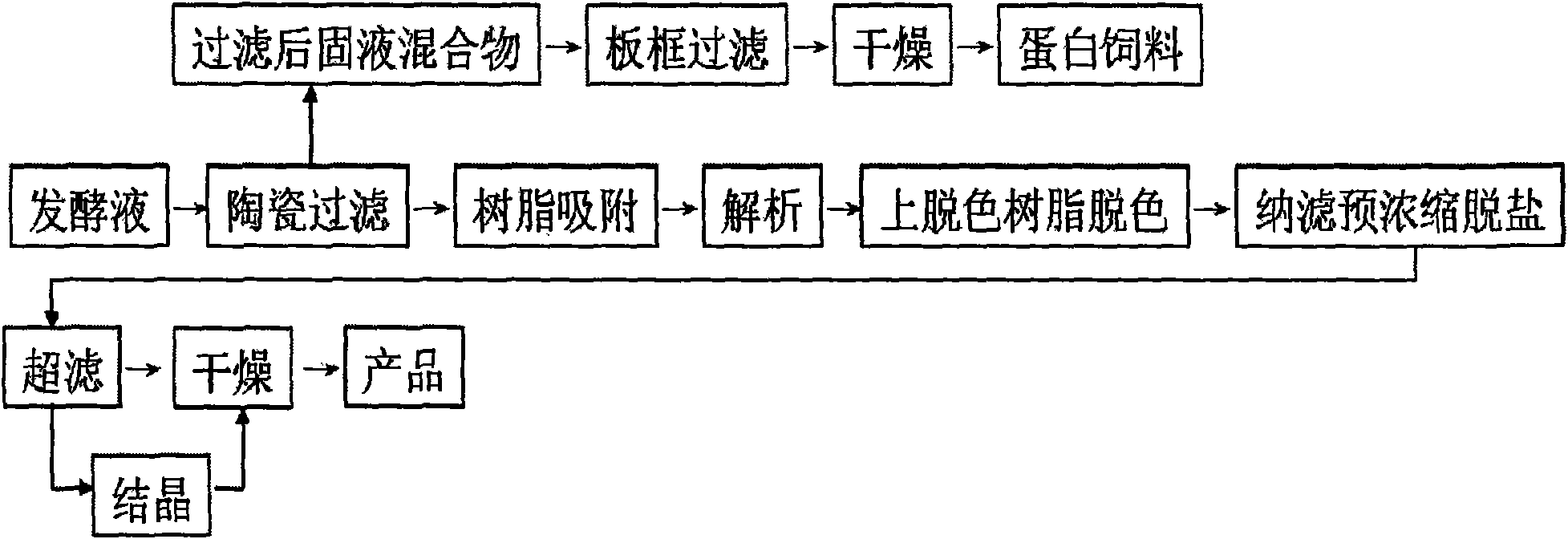

[0024] Such as figure 2 The process flow diagram for the extraction of L-tryptophan in the fermented liquid of the present invention shown, fermented liquid 1000ml (fermented liquid specific gravity 0.98, solid matter percentage content 18%, wherein L-tryptophan 250g) passes through Al 2 o 3 The ceramic membrane with a mass percentage of 99% is used for filtration, the pore size of the ceramic membrane is 0.1 μm, and the filtration flux is 10l / m 2 h, the solid-liquid mixture filtered by ceramic membrane (the main component is biological protein, solid content 35%) is filtered by plate and frame, dried and used as protein feed. Adsorption, adsorption flow 3m 3 / h, the batch adsorption time is 8h, and then analyze with 0.5mol / l ammonia water, the analysis flow rate is twice the volume of the resin per hour, and the analysis solution is sent to the basic anion resin D315 column for decolorization, and the decolorization solution is first filtered by nanofiltration Membrane (t...

Embodiment 2

[0026] The difference from Example 1 is that the saturated solution obtained after ultrafiltration is adjusted to a pH of 2.0 with sulfuric acid with a mass concentration of 20% to induce crystallization of L-tryptophan, and then dried to obtain 235.5 g of L-tryptophan product, the product The yield is 94.2%, and the content is 98.6%.

Embodiment 3

[0028] Such as figure 2 The extraction process flow diagram of L-tryptophan in the fermented liquid of the present invention shown, fermented liquid 1000ml (fermented liquid specific gravity 0.98, solid matter percentage content 20%, wherein L-tryptophan 250g) passes through Al 2 o 3 The ceramic membrane with a mass percentage of 99% is used for filtration. The pore size of the ceramic membrane is 0.3 μm, and the filtration flux is 30l / m 2 h, the solid-liquid mixture filtered by ceramic membrane (the main component is biological protein, the solid content is 40%) is filtered by plate and frame, dried and used as protein feed, and the filtered clear liquid is used as strong acid cation adsorption resin JK008 column Adsorption, adsorption flow 3.5m 3 / h, the batch adsorption time is 10h, and then analyze with 1mol / l ammonia water, the analysis flow rate is 2.5 times the volume of the resin per hour, and the analysis solution is sent to the basic anion resin D305 column for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com