Manufacturing technique of reactive power concrete products

A technology for concrete products and production methods, which is applied in the field of production process methods for reactive powder concrete products, can solve the problems of no production process and restrict the application of reactive powder concrete products, etc., and achieves the effects of high production efficiency, easy realization and solving process bottlenecks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Vibration molding process for reactive powder concrete products.

[0068] Take this process to form a 400mm×400mm×1500mm square beam specimen as an example.

[0069] Described active powder concrete is by following mass ratio (kg / m 3 Count) raw material composition:

[0070] Ordinary silicon 42.5 cement 653-732 kg; S i o 2 189-235 kg of admixture with an average particle size of 0.31 μm and a maximum particle size of 0.5 μm; 1125-1310 kg of quartz sand with a particle size of 0.16-1.25 mm; 35-70 kg of admixture; 110-145 kg of water kg; steel fiber diameter 0.16-0.3mm 65-143 kg;

[0071] The slump of reactive powder concrete is not less than 200mm.

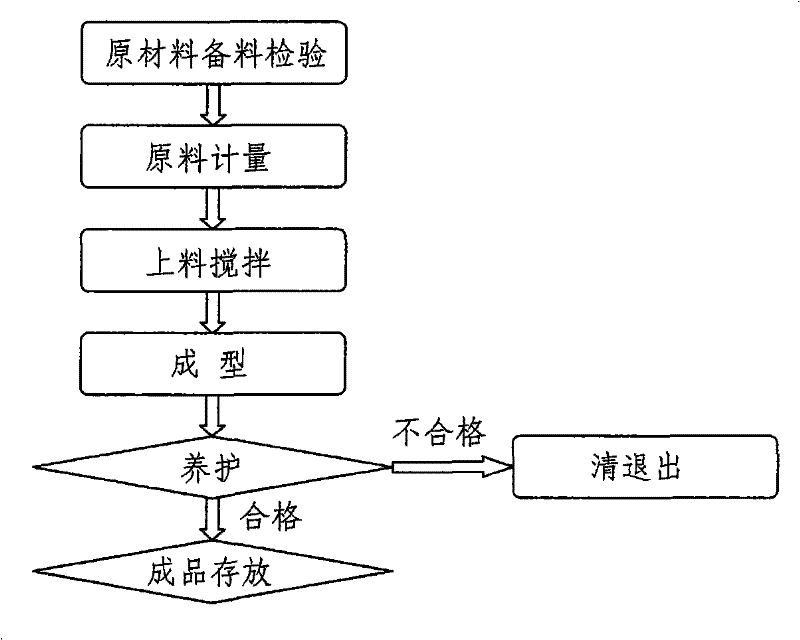

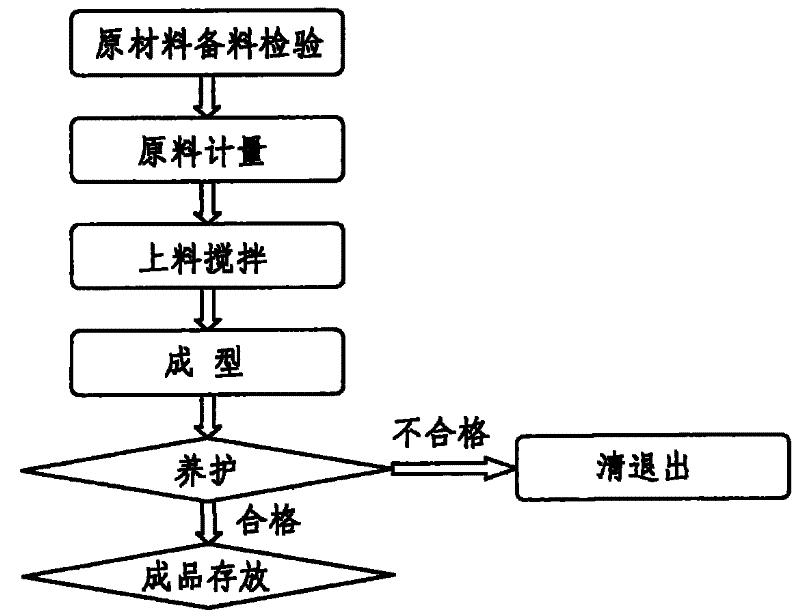

[0072] Active powder concrete products are molded according to the following steps in sequence, and the required raw materials are expressed in kg / m 3 count:

[0073] (1) Dissolve 50kg of non-naphthalene-based water reducer in 130kg of measured water (dissolve in water first to prevent uneven stirring when directly ad...

Embodiment 2

[0081] Vibration molding process for reactive powder concrete products.

[0082] Take this process to form a 2000mm×800mm×100mm hollow plate specimen as an example.

[0083] Described active powder concrete is by following mass ratio (kg / m 3 Count) raw material composition:

[0084] Ordinary silicon 42.5 cement 653-732 kg; S i o 2 189-235 kg of admixture with an average particle size of 0.31 μm and a maximum particle size of 0.5 μm; 1125-1310 kg of quartz sand with a particle size of 0.16-1.25 mm; 35-70 kg of admixture; 110-145 kg of water kg; steel fiber diameter 0.16-0.3mm 65-143 kg.

[0085] The slump of reactive powder concrete is not less than 200mm.

[0086] Active powder concrete products are molded according to the following steps in sequence, and the required raw materials are expressed in kg / m 3 count:

[0087] (1) Dissolve 45kg of non-naphthalene-based water reducer in 130kg of measured water (dissolve in water first to prevent uneven stirring when directly a...

Embodiment 3

[0095] Vibration Forming Technology of Active Powder Concrete

[0096] Use this process to form a 750mm×500mm×25mm specimen as an example.

[0097] Described active powder concrete is by following mass ratio (kg / m 3 Count) raw material composition:

[0098] Ordinary silicon 42.5 cement 653-732 kg; S i o 2 189-235 kg of admixture with an average particle size of 0.31 μm and a maximum particle size of 0.5 μm; 1125-1310 kg of quartz sand with a particle size of 0.16-1.25 mm; 35-70 kg of admixture; 110-145 kg of water kg; steel fiber diameter 0.16-0.3mm 65-143 kg.

[0099] The slump of reactive powder concrete is not less than 150mm.

[0100] Active powder concrete products are molded according to the following steps in sequence, and the required raw materials are expressed in kg / m 3 count:

[0101] (1) Dissolve 35kg of non-naphthalene-based water reducer in 130kg of measured water (dissolve in water first to prevent uneven stirring when directly added to other raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com