Novel casting method and mould

A casting mold and pressurizing device technology are applied to the casting mold. It can solve problems such as affecting product quality stability and yield, unstable pouring conditions, and inability to rise to the pressure value, and achieve the effects of good mechanical properties and mechanical properties, reduced production space, and reduced pouring temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The casting mold has a simple structure, and the specific structure has been introduced before, and the specific implementation will be described in conjunction with the operation process below.

[0051] The operating process of the present invention comprises the following steps:

[0052] a. Preparatory work, including molten metal, preheating casting molds, coating, assembling casting molds, etc.;

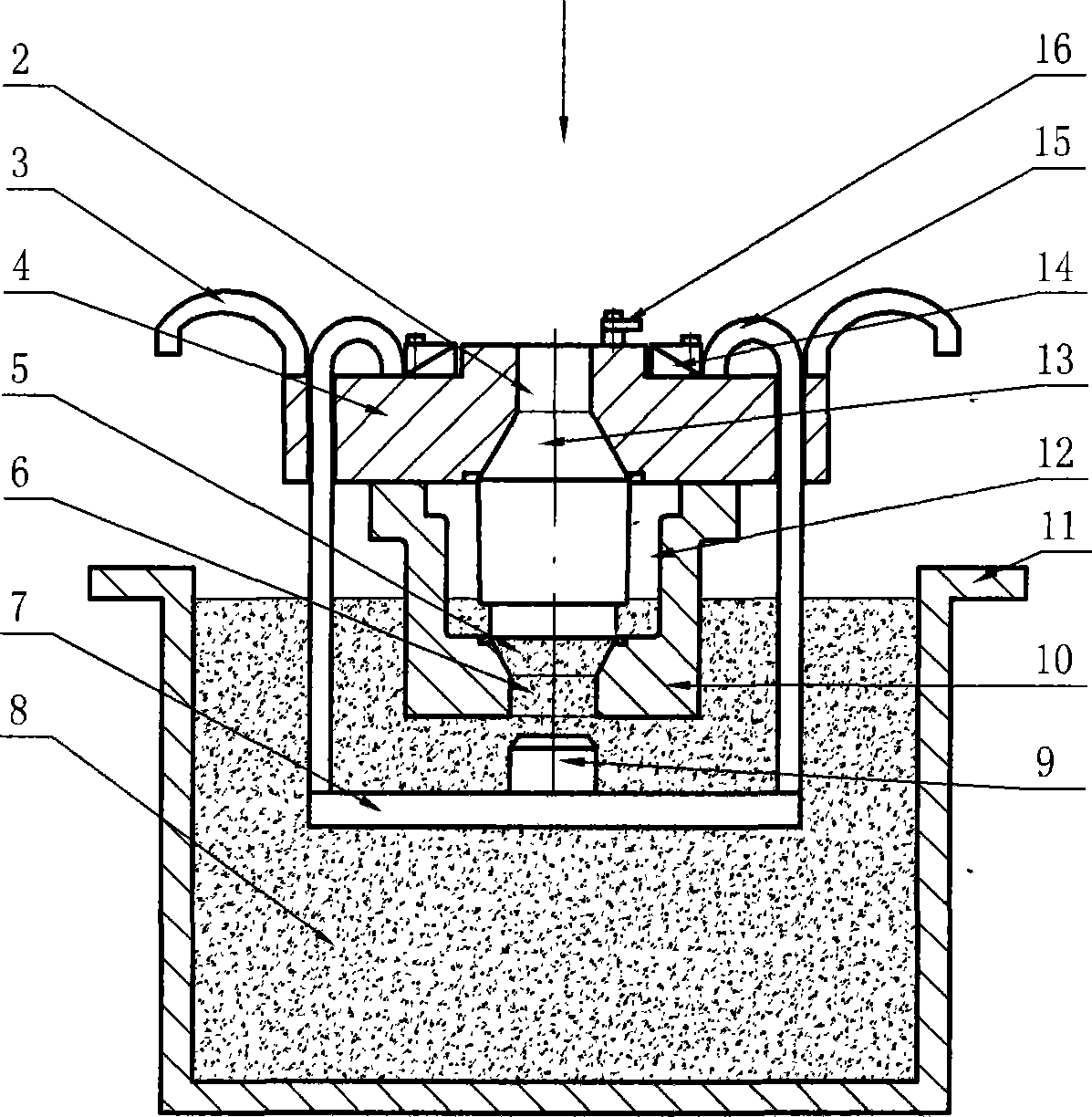

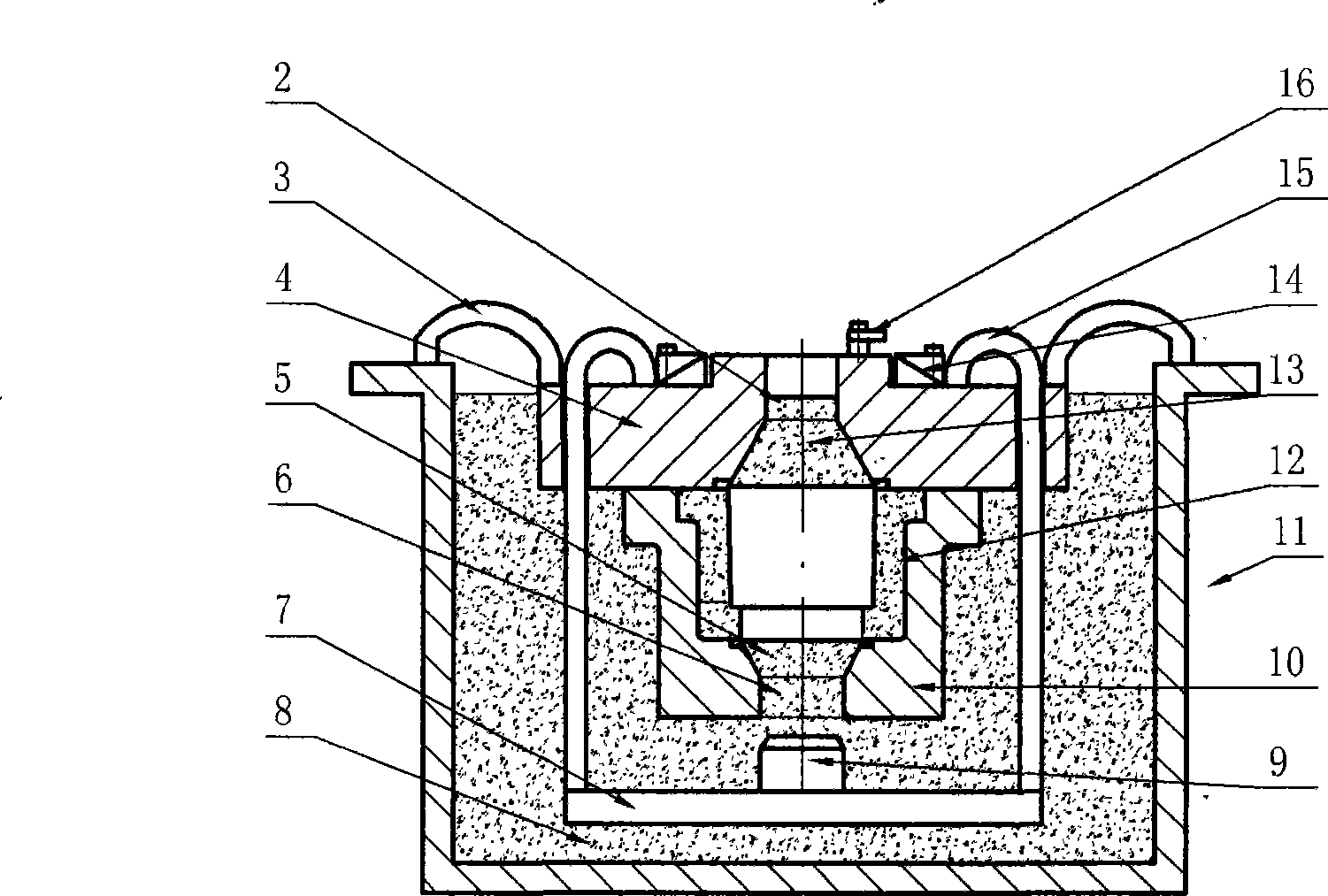

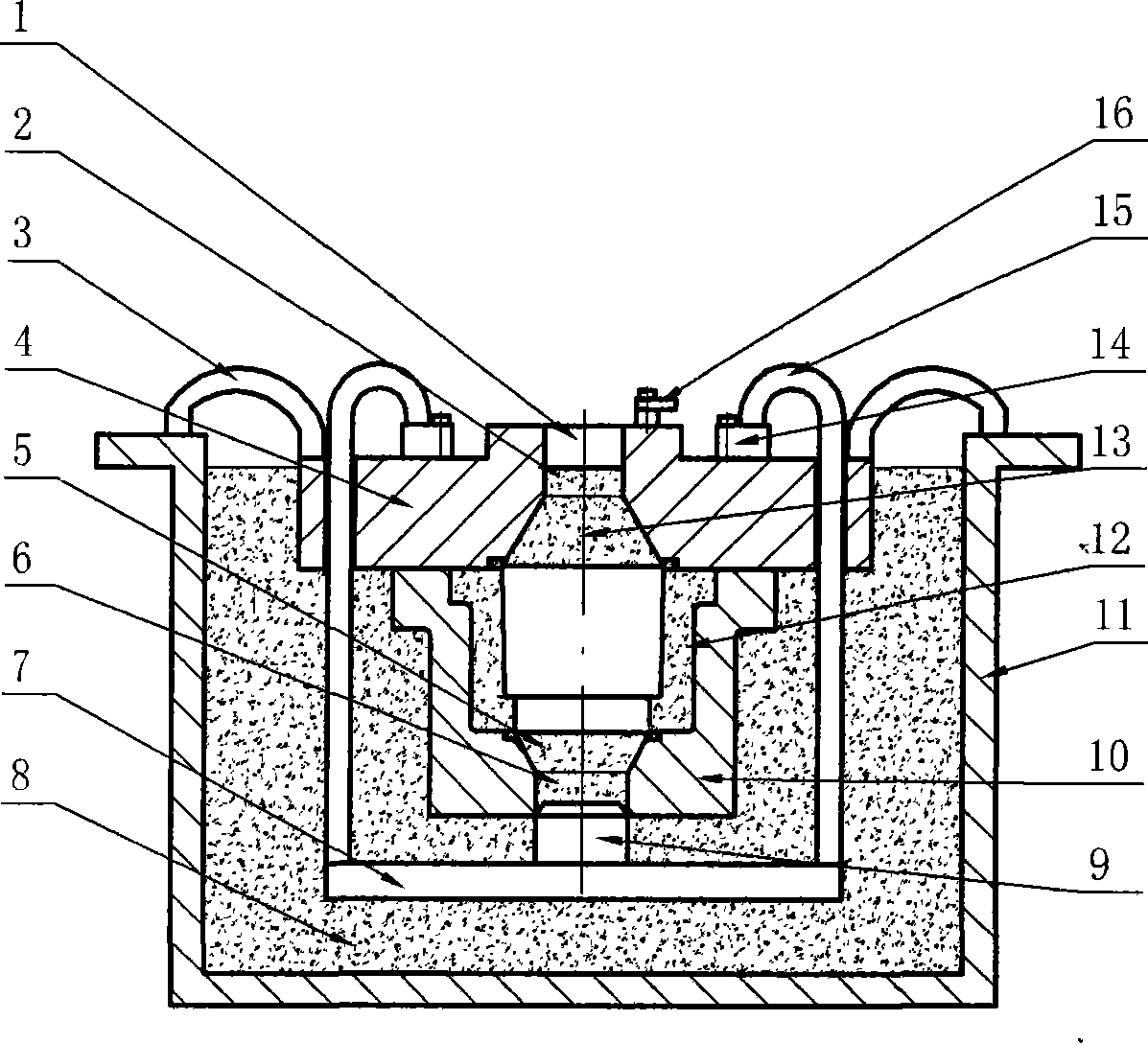

[0053] b. Hook the fixed lifting ring (3) with a sling, slowly immerse the casting mold in the molten metal (8), the lower pressure plug (9) will leave the gate (6) due to its own weight, and the molten metal (8) will The lower feeding cavity (5), the mold cavity (12), the upper feeding cavity (13) and part of the opening (2) are filled sequentially through the gate (6) until the fixed lifting ring (3) rests on the molten pool ( 11) On the edge or on the special shelf, complete the pouring work, remove the spreader, such as figure 1 with figure 2 shown;

[0054] c. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com