Combustion method for garage kit mold block of vacuum evanescent mold

A technology of vacuum lost foam and combustion method, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as adverse effects of castings, and achieve the effects of eliminating carbon increase, reducing difficulty, and simplifying casting process parameter control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

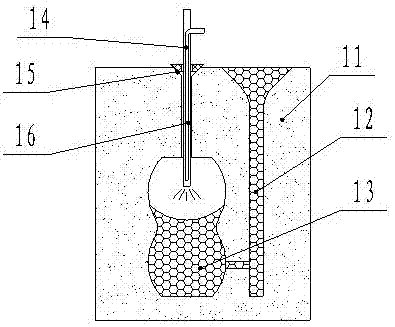

[0024] figure 1 It is a schematic diagram of the combustion process of the white mold module of the present invention. Before molding, the casting white mold module 13 is bonded to the outlet 16, painted with paint, and then the pouring system 12 is bonded. Place the modules after the box assembly in the sand box 11 to add sand and vibrate for molding. After the modeling is completed, cover it with plastic film. Vacuum the sandbox before pouring.

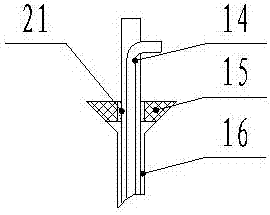

[0025] Incendiary gun 14 is inserted in the sealing block 15, ignites incendiary gun 14, and with incendiary gun 14 earlier outlet 16 is burnt, as attached figure 2 As shown, the outlet 16 is sealed with a sealing block 15, and the gap between the combustion gun 14 and the sealing block 15 is sealed with refractory cotton 21 simultaneously.

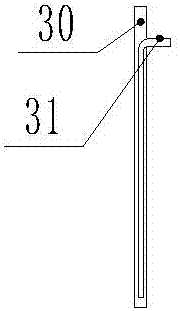

[0026] The above steps can also be changed to: first use the combustion gun 14 to burn the outlet 16 to prepare for the sealing of the sealing block 15 . Then combustion gun 14 is passed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com