Production technology of air-conditioning compressor crankshaft

A technology for air-conditioning compressors and production processes, which is applied to manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve problems such as low production efficiency, waste of molding sand, and fewer production crankshafts, so as to reduce the pouring temperature and improve the process. Yield, the effect of shortening the pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

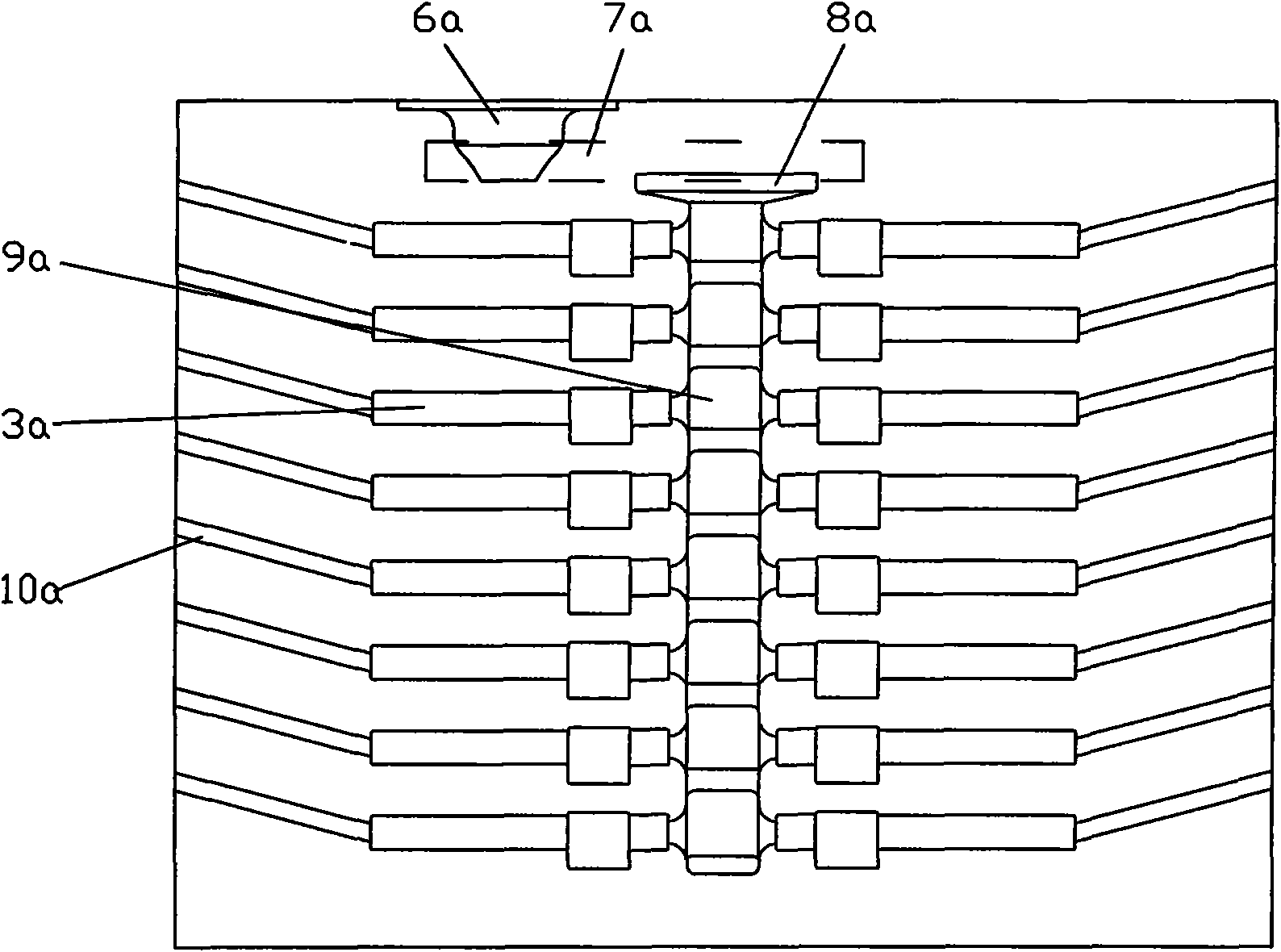

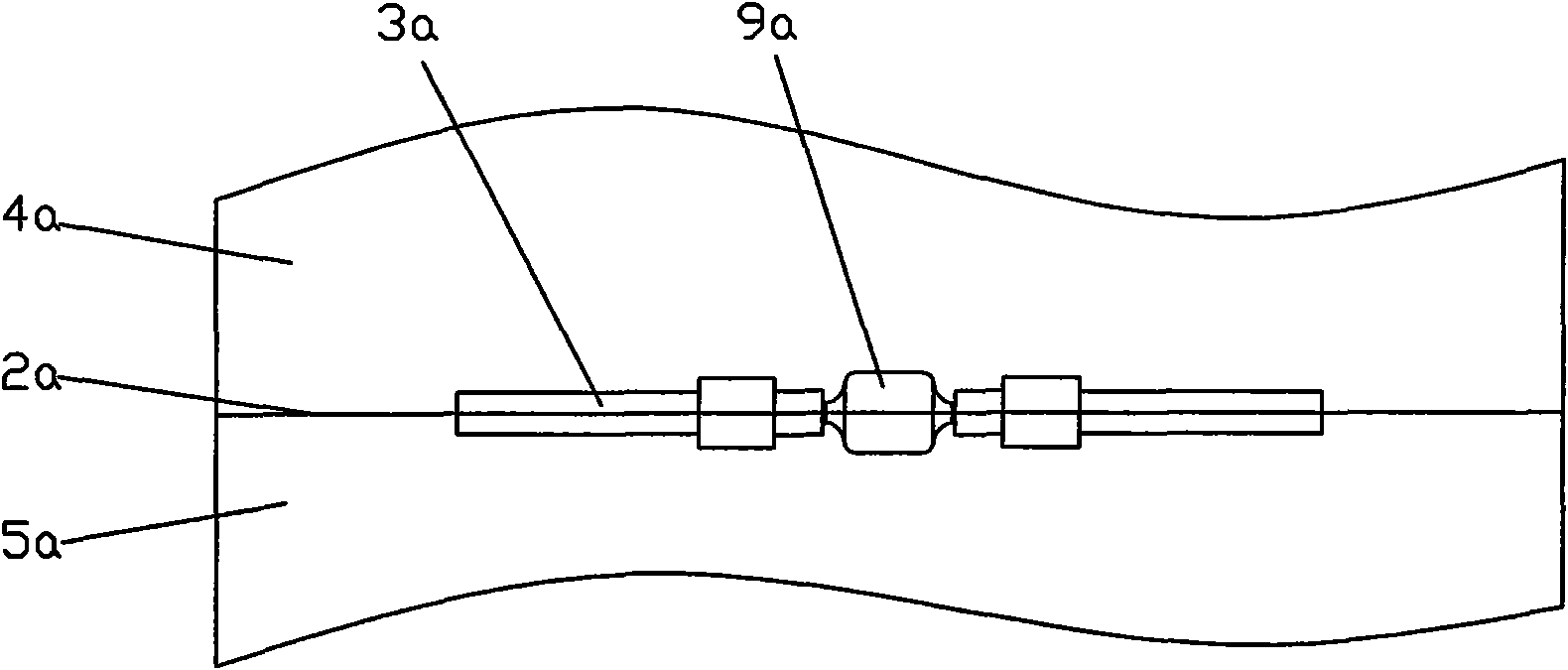

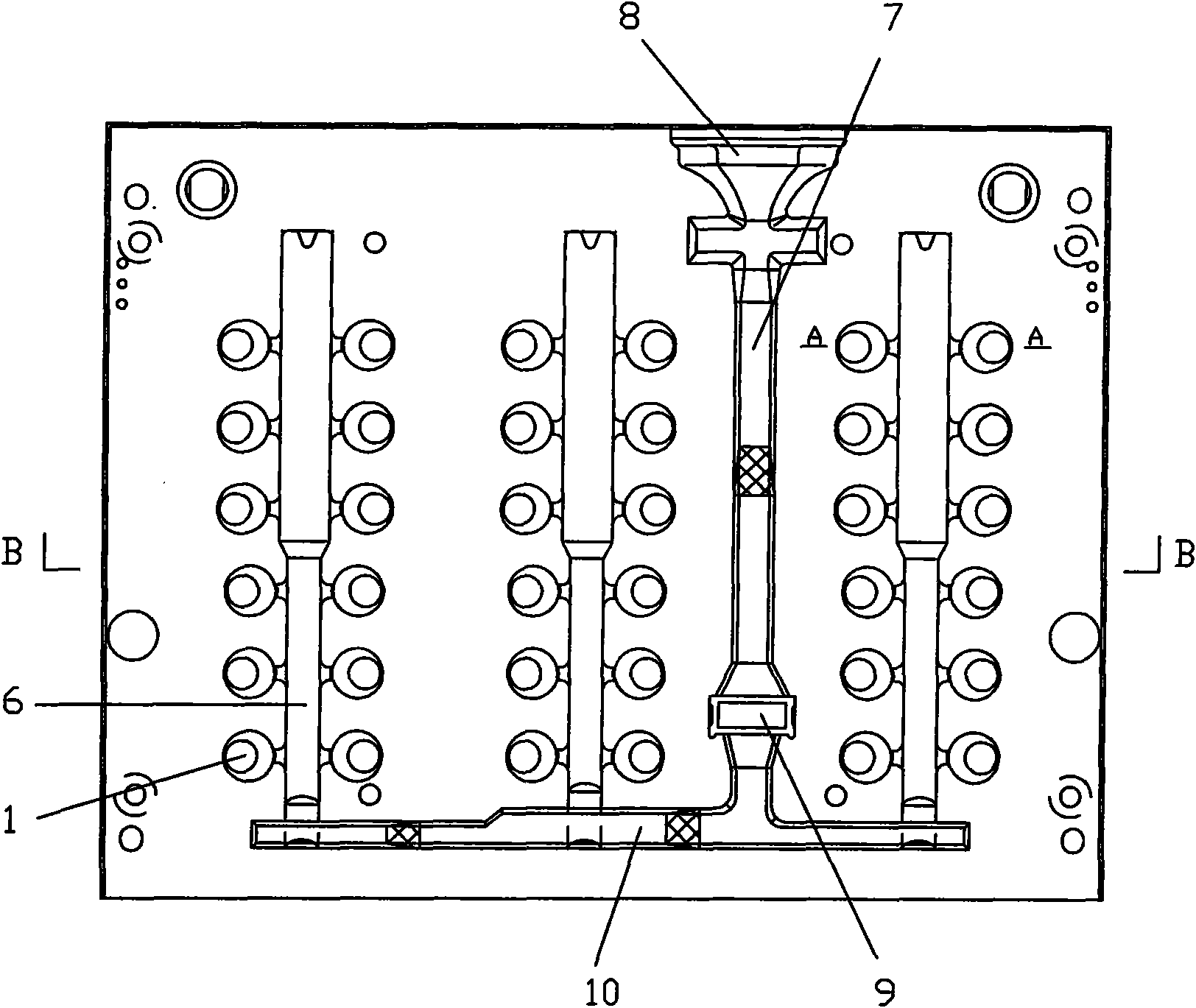

[0019] see figure 2 , image 3 , air-conditioning compressor crankshaft production technique of the present invention, comprises the steps:

[0020] 1. Sand mixing

[0021] According to the proportion of molding sand ingredients (92-100% of old sand, 0-8% of new sand, 0.5-2.5% of bentonite and 0-0.1% of coal powder), respectively add old sand, new sand and auxiliary materials for dry mixing for 10s-20s, roughly add water and wet mix for 120s -150S, finely add water and mix for 15s-25s, sand will come out after passing the test, and the mixing time is 2 to 3 minutes. Molding sand performance requirements meet: compaction rate 33-43%, moisture 2.9-3.6%, air permeability > 100, wet compressive strength 0.09-0.17Mpa, effective bentonite 6.0-9.5%, mud content 9.0-15.0%, burning reduction Quantity 2.0-4.0%, volatile matter 1.0-3.0%.

[0022] 2. Shape and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com