Forming device and method for preparing high-structural strength aluminum alloy hub

An aluminum alloy wheel hub and high-structure technology, which is applied in the field of forming devices for preparing high-strength aluminum alloy wheel hubs, can solve the problems of low production efficiency, high manufacturing cost, complicated process, etc., and achieve automatic production, strong market competitiveness, The effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] (1) Melt the A356 aluminum alloy ingot in a resistance furnace, and use a rotary blowing device to degas and refine the alloy melt at 720°C. The time for degassing and refining is 20 minutes, and stand for 10 minutes after the treatment is completed. , the temperature is controlled at 670°C, and it is ready for use;

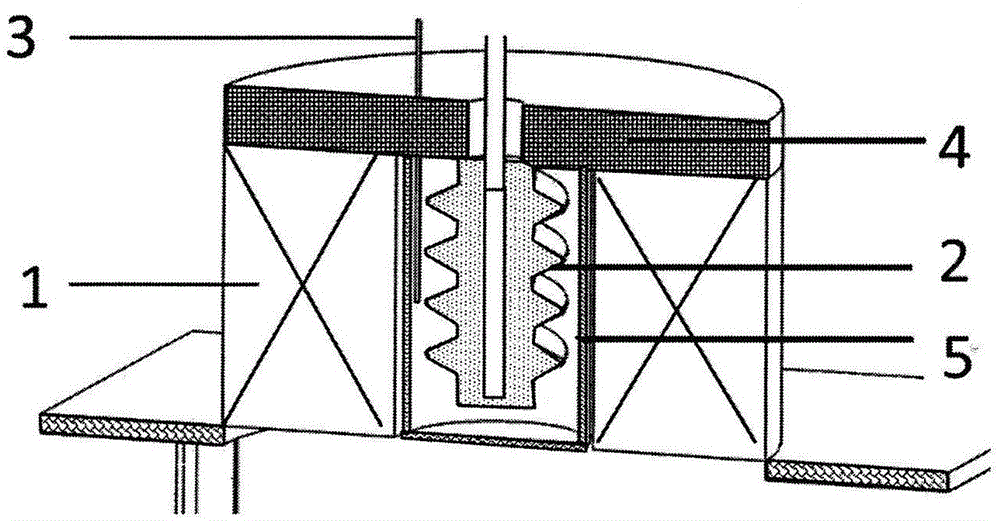

[0030] (2) Utilize the quantitative pouring cup to quantitatively transfer the A356 alloy melt after refining and standing to the graphite crucible 5, and the graphite crucible 5 is preheated to 500°C, as figure 1 As shown, the graphite crucible 5 was put into a spiral electromagnetic stirrer, and the semi-solid slurry was prepared by the spiral electromagnetic stirring method. Wherein, an electromagnetic stirring coil 1 is used for electromagnetic stirring, and a single-screw mandrel 2 and a temperature-controlling thermocouple 3 are arranged in the spiral electromagnetic stirrer. For heat insulation, a heat insulating cover plate 4 is arranged in the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com