Method for realizing low superheat pouring of continuous casting process by using high-intensity magnetic field, and device for method

A technology of superheat degree and strong magnetic field, applied in the field of casting process and its equipment, can solve the problems of increasing the degree of nucleation and supercooling, and achieve the effects of increasing the degree of nucleation and supercooling, inhibiting nucleation, and simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

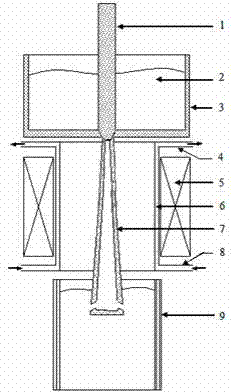

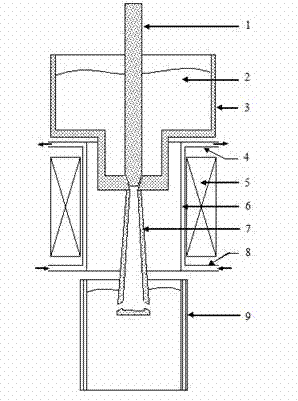

[0025] A method of using a strong magnetic field to achieve low superheat pouring in the continuous casting process. By using a strong magnet to generate a constant strong magnetic field inside the tundish and the nozzle, under the action of the constant strong magnetic field, the metal melt flows through the nozzle It remains liquid below the liquidus temperature, that is, when it flows through the nozzle, the metal melt is in a supercooled state or a low superheated state without solidification, so that the metal melt flowing out of the outlet at the bottom of the nozzle is supercooled or low superheated. Heat way pouring into the crystallizer. In this embodiment, a stable and constant strong magnetic field is used to suppress the nucleation of the metal melt, increase the nucleation supercooling degree, and carry out low superheat pouring by synergistically controlling the superheat and subcooling of the metal melt to overcome the low superheat pouring process. The easy-to-...

Embodiment 2

[0030] The technical solution of this embodiment is basically the same as that of Embodiment 1, especially in that:

[0031] In this embodiment, in this embodiment, see figure 1 , Cooling device 6 adopts cooling air jacket. The cooling air jacket has an air outlet 4 and an air inlet 8 , and the height space position of the air outlet 4 is higher than that of the air inlet 8 . In this embodiment, the use of the cooling air jacket can save a lot of industrial water, reduce environmental pollution, and reduce infrastructure costs. Especially in water-scarce and dry climate areas, air cooling can be used instead of water cooling for continuous casting production.

Embodiment 3

[0033] The technical solutions of this embodiment are basically the same as those of the foregoing embodiments, and the special features are:

[0034] In this example, see figure 2 At the same time, the strong magnet 5 is also installed on the outside of the tundish 3 in a non-contact manner, and the cooling device 6 is also installed between the tundish 3 and the strong magnet 5, and the strong magnet 5 generates a constant strength inside the tundish 3 The magnetic field controls the degree of superheating and subcooling of the molten metal 2 cooperatively. When the nozzle 7 is opened, the molten metal 2 flows smoothly from the tundish 3 through the nozzle 7 . In this embodiment, not only the strong magnet 5 is installed at the nozzle position, but also the strong magnet 5 applies a constant strong magnetic field to the metal melt 2 in the tundish 3, which expands the intervention area of the external magnetic field and strengthens the constant temperature strong magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com