Preparation method of copper-zinc composite plates and strips

A composite strip, copper-zinc technology, applied in the direction of metal rolling, etc., can solve the problems of insufficient bonding strength and low composite sheet strength, achieve good mechanical properties, improve metallurgical bonding quality, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the copper-zinc composite strip of the present embodiment comprises the following steps:

[0023] 1) After the surface impurities are removed from the zinc ingot, it is smelted at 480°C to form a zinc liquid;

[0024] 2) making the zinc liquid obtained in step 1) into a semi-solid slurry;

[0025] 3) Preheat the surface-treated copper plate at 400°C, pour the slurry obtained in step 2) on the preheated copper plate, and roll it with a roll with a reduction of 50% at a rolling speed of 75mm / min, that is.

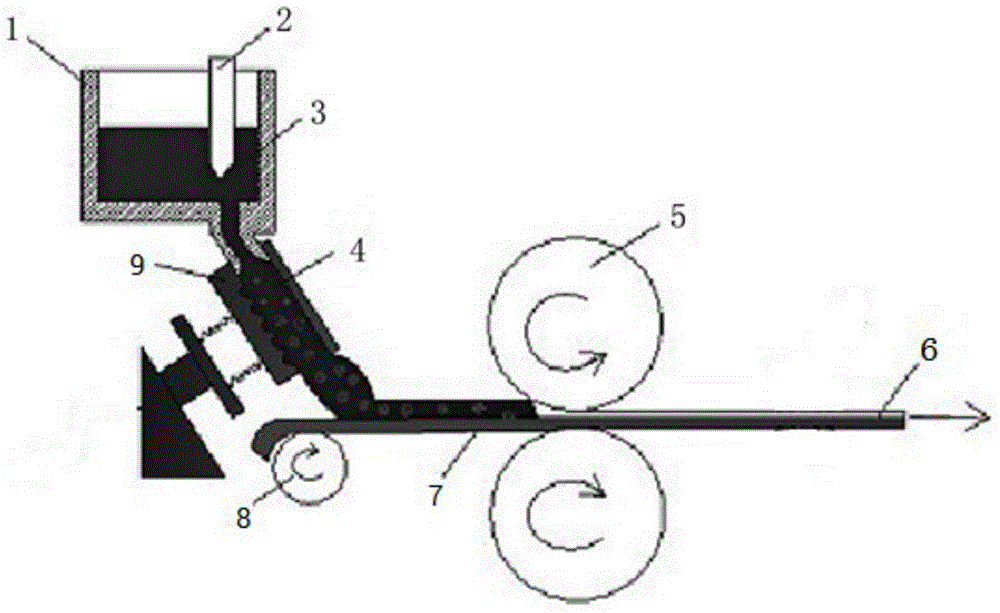

[0026] The composite strip continuous casting device realizing the above-mentioned preparation method of the present embodiment, such as figure 1 As shown, it includes a crucible 1, a vibrating pulping device 9, a heat conduction roller 8 and a rolling device 5, the bottom of the crucible 1 is provided with a liquid outlet, and the liquid outlet communicates with the liquid inlet of the vibrating pulping device 9, The slurry outlet of the ...

Embodiment 2

[0029] The preparation method of the copper-zinc composite strip of the present embodiment comprises the following steps:

[0030] 1) After the surface impurities are removed from the zinc ingot, it is smelted at 420°C to form a zinc liquid;

[0031] 2) making the zinc liquid obtained in step 1) into a semi-solid slurry;

[0032] 3) Preheat the surface-treated copper plate at 500°C, pour the slurry obtained in step 2) on the preheated copper plate, and roll it with a roll with a reduction of 35% at a rolling speed of 100mm / min, that is.

[0033] The composite strip continuous casting device for realizing the above preparation method in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0035] The preparation method of the copper-zinc composite strip of the present embodiment comprises the following steps:

[0036] 1) After the surface impurities are removed from the zinc ingot, it is smelted at 450°C to form a zinc liquid;

[0037] 2) making the zinc liquid obtained in step 1) into a semi-solid slurry;

[0038] 3) Preheat the surface-treated copper plate at 600°C, pour the slurry obtained in step 2) on the preheated copper plate, and roll it with a roll with a reduction of 20% at a rolling speed of 50mm / min, that is.

[0039] The composite strip continuous casting device for realizing the above preparation method in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com