Horizontal electromagnetic continuous casting equipment for copper alloy sheet

A copper alloy plate and horizontal technology, applied in the field of non-ferrous metallurgy and non-ferrous metal processing and preparation, can solve the problems of electromagnetic modification of horizontal continuous casting copper alloy plate and strip, achieve uniform solidification structure, reduce pouring temperature, and install simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

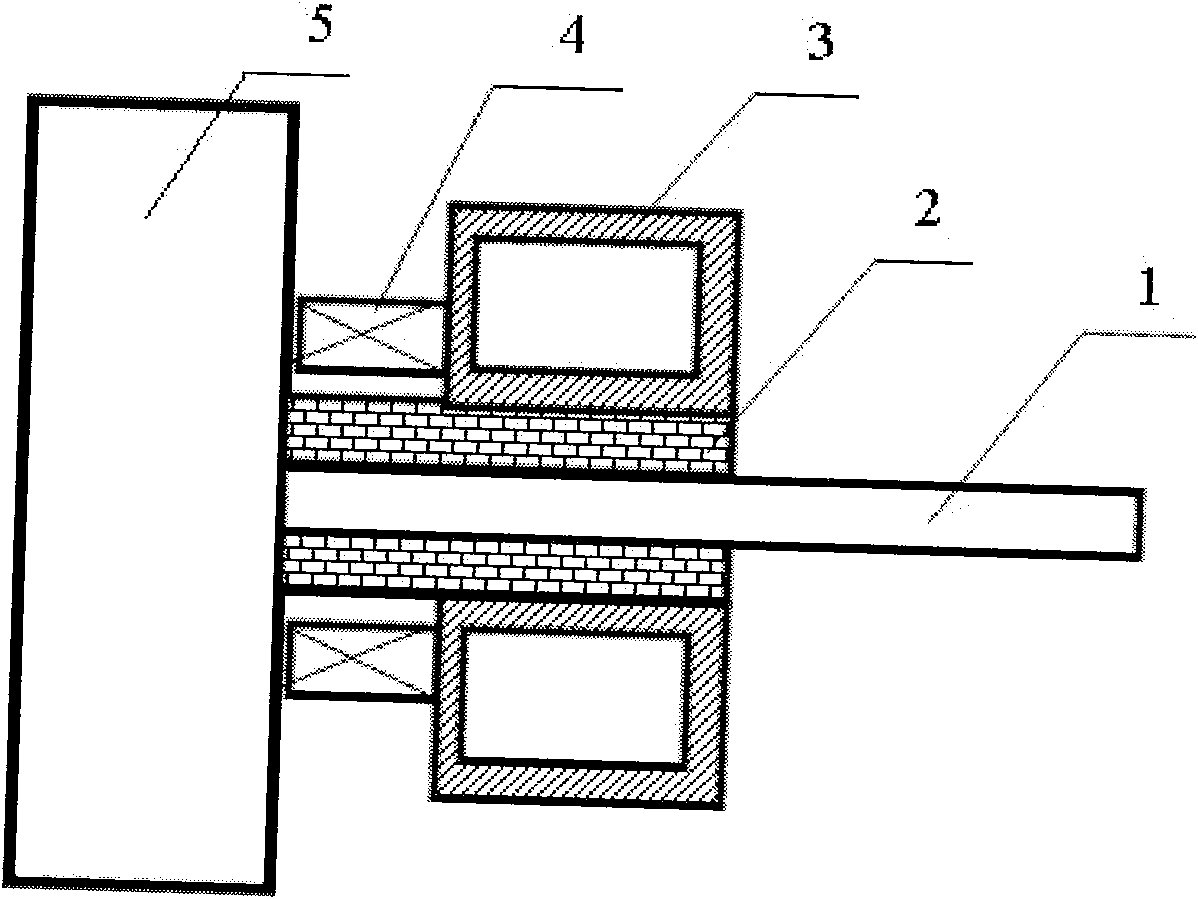

[0019] Fix the traveling wave linear magnetic field generator 4 on the front end of the horizontal continuous casting plate with water-cooled copper sleeve 3 and the upper side of the graphite crystallizer 2. Connect the terminal to a 50 Hz three-phase AC power supply, and then connect the graphite crystallizer with the cooling system Installed on the holding furnace 5, when the tin-phosphorus bronze liquid QSn6.5-0.1 in the holding furnace reaches 1140-1170°C, the tractor is started to start continuous casting. Turn on the power switch, by observing the color and solidification marks on the surface of the slab blank 1, adjust the current and the direction of the current flowing into the magnetic field generator until the surface color is gray and white and the solidification marks are straight. Maintain this stable state. produce.

[0020] Use a shear trigger to intercept the strip sample, observe its solidified structure, and test its mechanical properties. The yield strength ...

Embodiment 2

[0022] The two traveling wave linear magnetic field generators 4 are respectively fixed on the front end of the horizontal continuous casting plate with water-cooled copper sleeve 3, the upper and lower sides of the graphite crystallizer 2, and the connection terminals are connected to the 30 Hz two-phase AC power supply, and then the graphite The crystallizer and the cooling system are installed on the holding furnace. When the brass copper liquid H65 in the holding furnace reaches 1050-1080°C, the tractor is started to start continuous casting. Turn on the power switch, observe the surface condition of the slab blank 1, adjust the current and the direction of the current flowing into the magnetic field generator, until the surface color is gray and white and the solidification marks are straight, maintain this stable state and proceed with production.

[0023] Use a shear trigger to intercept the strip sample, observe its solidified structure, and test its mechanical properties....

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com