A kind of flash steam cleaning method

A technology of flash steam and steam, which is applied in the field of flash steam cleaning, and can solve problems such as long steam injection time, large steam flow rate, and steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

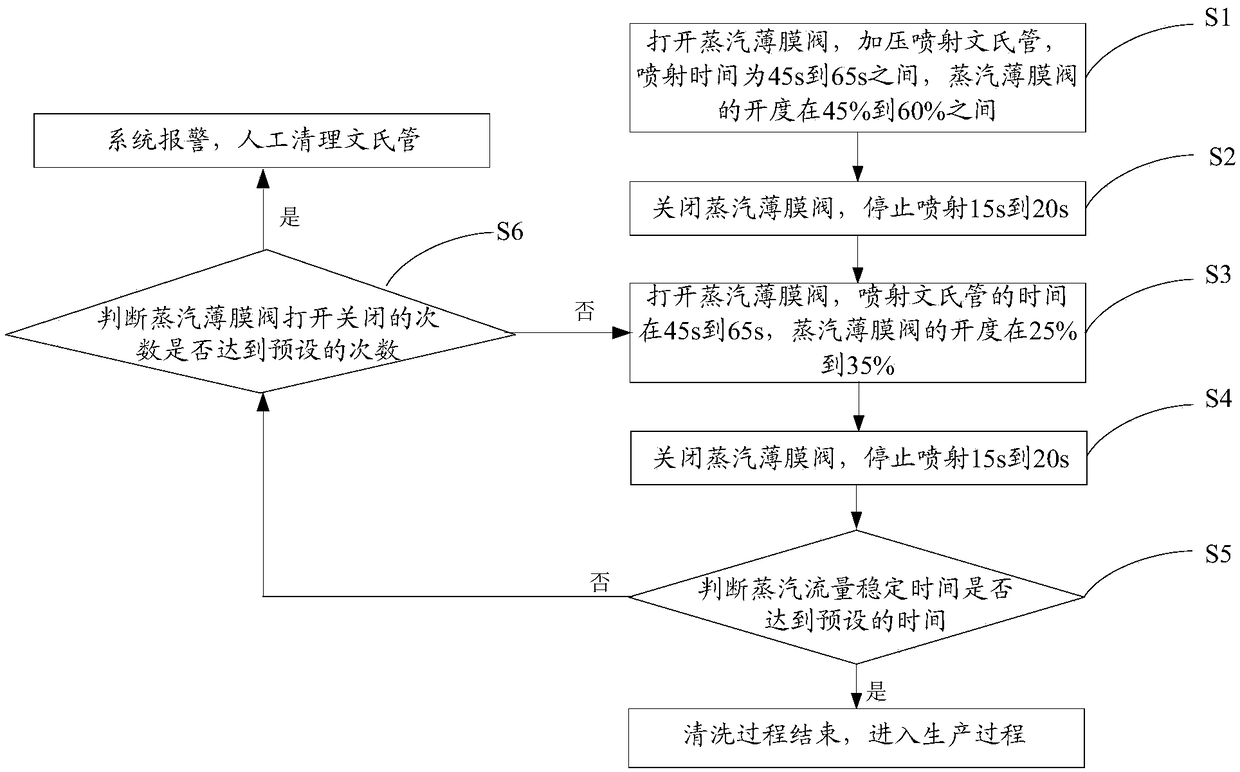

[0021] see figure 1 , figure 1 A flow chart of a flash steam cleaning method is provided for the present invention.

[0022] The invention discloses a flash steam cleaning method, comprising the following steps:

[0023] Step S1: Open the steam membrane valve, pressurize and inject the venturi tube, the injection time is between 45s and 65s, and the opening of the steam membrane valve is between 45% and 60%.

[0024] When starting cleaning, due to the large amount of material, the steam membrane valve is adjusted to a large opening. Here, the inventor has obtained through experiments that the opening of the steam membrane valve is greater than or equal to 45%, and the opening of the steam membrane valve is less than or equal to 60%. , the pressurized injection to the Venturi tube can be realized, and the injection time is greater than 45s and less than 65s.

[0025] Step S2: Close the steam membrane valve and stop spraying for 15s to 20s.

[0026] Close the steam membrane ...

Embodiment 2

[0042] In yet another embodiment provided by the present invention, the flash steam cleaning method in this embodiment is similar to the flash steam cleaning method in Embodiment 1, and the similarities will not be repeated, and only the differences will be introduced.

[0043] In this embodiment, the inventor has obtained through multiple tests that the preset time in step S5 is 150 s, and the preset number of times in step S6 is 9 times, the blowing and cleaning of the venturi tube can be realized.

[0044] In the present embodiment, the opening of the steam film valve in step S1 is 45%, and the blowing time is 65s; the opening of the steam film valve in step S3 is 30%, and the blowing time is 65s; in steps S2 and S4 The closing time is 20s as an example for illustration.

[0045] After testing, the steam consumption of a single batch is about 65.5kg in the method of this embodiment; while the steam consumption of a single batch in the prior art is about 581.4kg, compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com