Highly effective metallurgical complexing agent for convertor (electric oven) and its preparation method and uses

A compound agent and high-efficiency technology, applied in the field of molten alloy processing, can solve the problems of high charge consumption and oxygen lance consumption, inability to meet desulfurization S, poor slag melting, etc., to achieve fast slag formation, shortened blowing time, The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Further illustrate the present invention by embodiment and industrial test below.

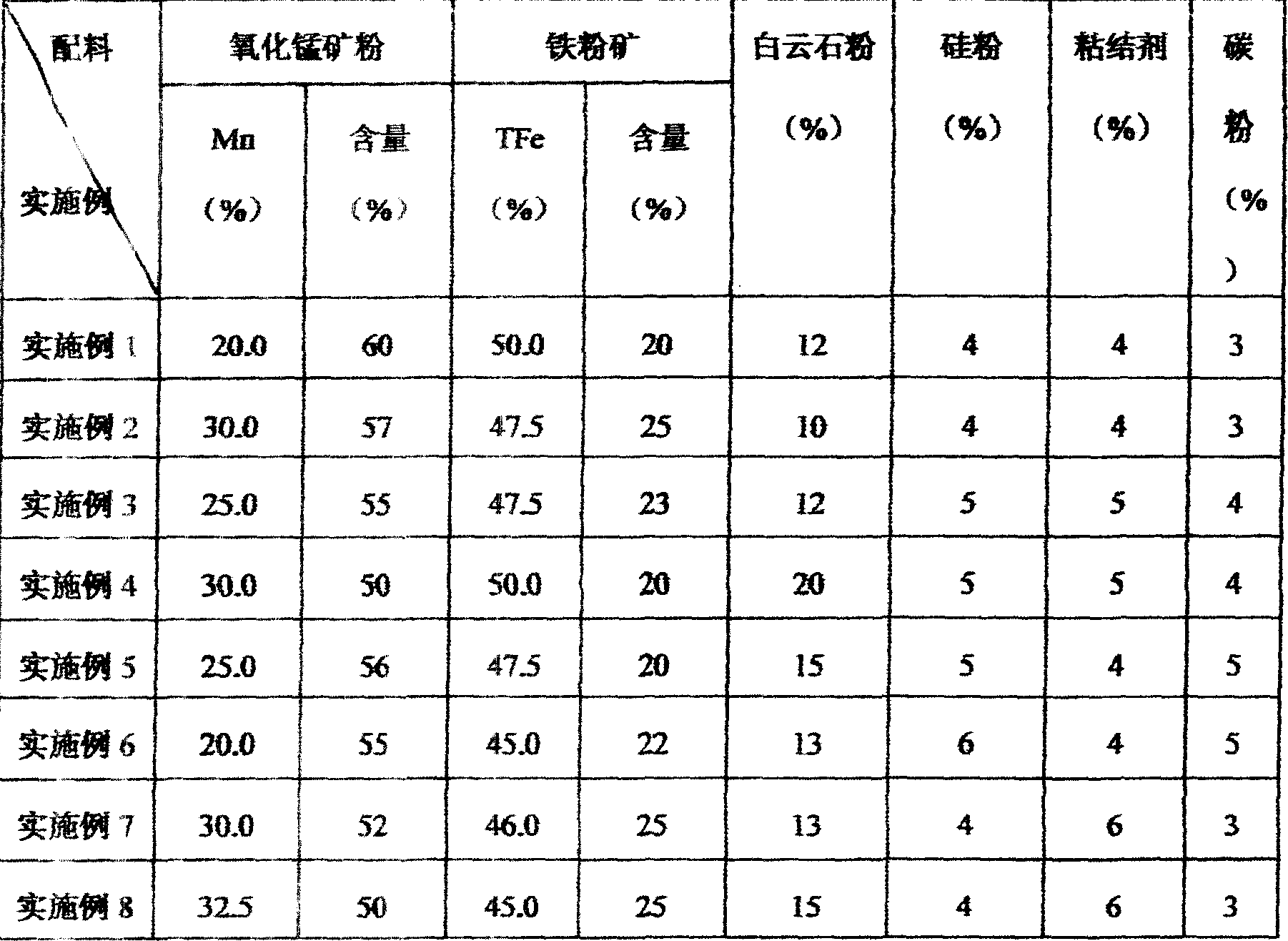

[0037] Under normal temperature and normal pressure, place manganese oxide ore powder, iron ore powder, dolomite powder, carbon powder, and silicon powder in a mixer to stir and mix them into a dry mixture according to the components and contents specified in Table 1; Add the binder to the dry powder, add an appropriate amount of water, and continue to stir and mix to form a wet mixture; put the wet mixture in a briquetting machine, and press it into a spherical body; dry and solidify; sieve and bag. Repeated many times, the results are listed in Table 1 and Table 2.

[0038] Table 1

[0039]

[0040] Example

apply effects

Q

α

W

T

P

1

600

0.021

l300

1-2

30-50

2

620

0.025

1500

1-2

30-50

3

650

0.030

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com