A hose blowing and drying device after static pressure detection

A drying device and post-testing technology, which is applied in the direction of drying gas arrangement, dryer for static materials, drying solid materials, etc., can solve the problems of low efficiency of blowing and drying rubber hoses, fewer rubber hoses, and easy water accumulation, etc. Achieve the effects of high blowing drying efficiency, improving utilization rate and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

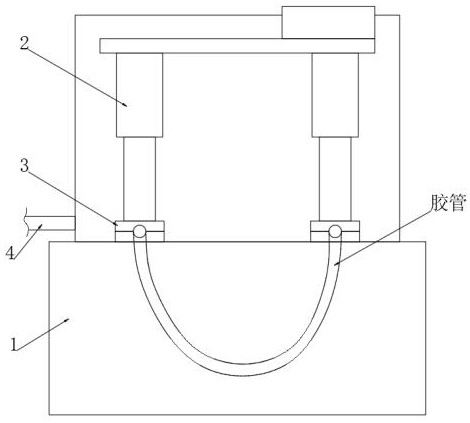

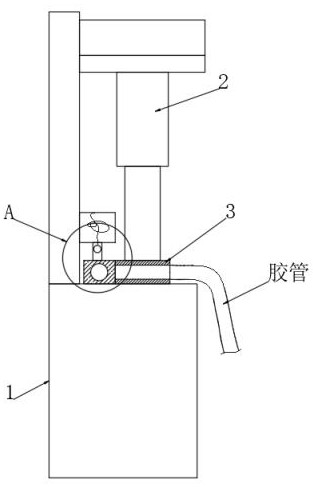

[0041] see figure 1 , a rubber hose blowing and drying device after static pressure detection, including a device body 1, a pair of cylinders 2 are installed on the upper end of the device body 1, a controller is connected to the upper end of the cylinder 2, and the upper end of the device body 1 and the lower end of the cylinder 2 are fixedly connected There are matching clamping plates 3, the two ends of the rubber hose are respectively clamped on two pairs of clamping plates 3, the outer end of the device body 1 is installed with an air intake pipe 4 connected to the blower, the blower and the cylinder 2 are connected with the controller electrical connection.

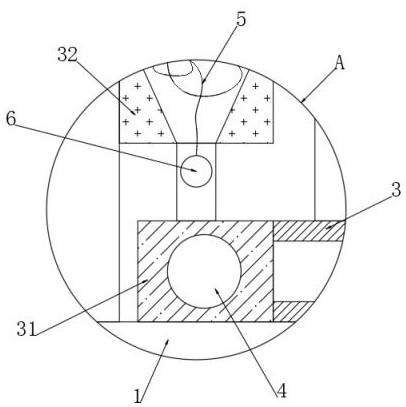

[0042] see Figure 2-3 The upper end of the device body 1 is fixedly connected with a multi-way pipe 31 that matches one of the pair of clamping plates 3. The multi-way tube 31 communicates with the air intake pipe 4 and the rubber tube whose end is located in the clamping plate 3. The upper end of the multi-way tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com