Car adjustor mould core manufacturing method

A manufacturing method and adjuster technology, which is applied in the manufacture of automotive adjuster molds and automotive adjuster mold core manufacturing, can solve the problems of difficulty in adapting to high precision, high manufacturing cost, and long replacement development cycle, etc., to improve working conditions and working environment, reducing blowing time, and eliminating the effect of air hole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

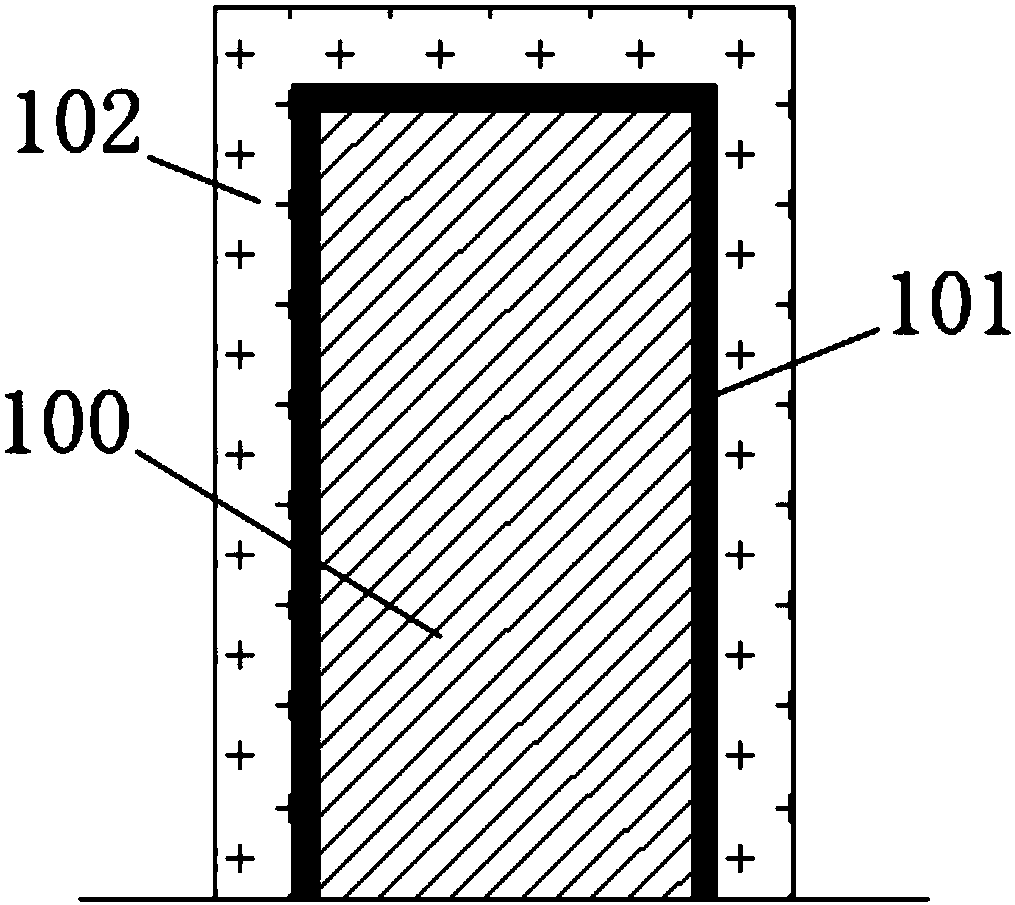

Image

Examples

Embodiment 1

[0042] First, 100 parts by weight of silica sand with a particle size of 0.15mm, 0.85 parts by weight of curing agent and 1.75 parts by weight of basic phenolic resin are mixed in sequence to obtain basic phenolic resin sand, and then the basic phenolic resin sand is added to the cold box core shooting In the core box of the machine, take out the core after forming and hardening in the core box, and then immerse the core in a mixed binder solution containing potassium tert-butoxide and tetraethyl orthosilicate for 10 minutes, and take out the mold from the mixed binder solution The core is dried in the air, and then the dried core is fired to above 1200 degrees Celsius, and then cooled; finally, the cooled core is de-cored to obtain the automobile regulator mold core.

Embodiment 2

[0044] First, 92 parts by weight of silica sand with a particle size of 0.10mm and 8 parts by weight of zirconium sand, 0.72 parts by weight of curing agent and 1.80 parts by weight of alkaline phenolic resin are mixed successively to obtain alkaline phenolic resin sand, and then the basic phenolic resin Sand is added to the core box of the cold box core shooter, and the core is taken out after being shaped and hardened in the core box, and then the surface enhancement solution is sprayed on the surface of the core taken out, and the surface enhancement solution contains organic resin, sodium aluminate and aluminum oxide nanoparticles, the average particle size of the aluminum oxide nanoparticles is 50nm; then the core is immersed in a mixed bonding liquid containing lithium tert-butoxide and tetraethyl orthosilicate for 15 minutes, and the mold is taken out from the mixed bonding liquid The core is dried in the air, and then the dried core is fired to above 1200 degrees Celsiu...

Embodiment 3

[0046] First, 95 parts by weight of silica sand with a particle size of 0.15 mm and 5 parts by weight of kaolin clinker sand, 0.85 parts by weight of curing agent and 1.70 parts by weight of alkaline phenolic resin are mixed in sequence to obtain alkaline phenolic resin sand, and then the alkaline Phenolic resin sand is added to the core box of the cold box core shooter, and shaped in the core box, after hardening, the core is taken out, and then the core is immersed in a mixed binder solution containing potassium tert-butoxide and ethyl orthosilicate for 8 minutes , taking out the core from the mixed bonding liquid and drying it in the air, and setting an aluminum oxide nanoparticle coating with an average particle diameter of 30 nm on the surface of the dried core, the thickness of the nano ceramic coating is preferably 30 μm; then The dried core is roasted to over 1200 degrees Celsius, then cooled; finally, the cooled core is removed to obtain the automobile regulator mold c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com