Mobile printing, positioning and conveying device

A technology of conveying device and positioning device, which is applied in printing, printing machine, transportation and packaging, etc. It can solve the problems of low paper feeding speed, short positioning time, poor stability of high-speed overprinting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

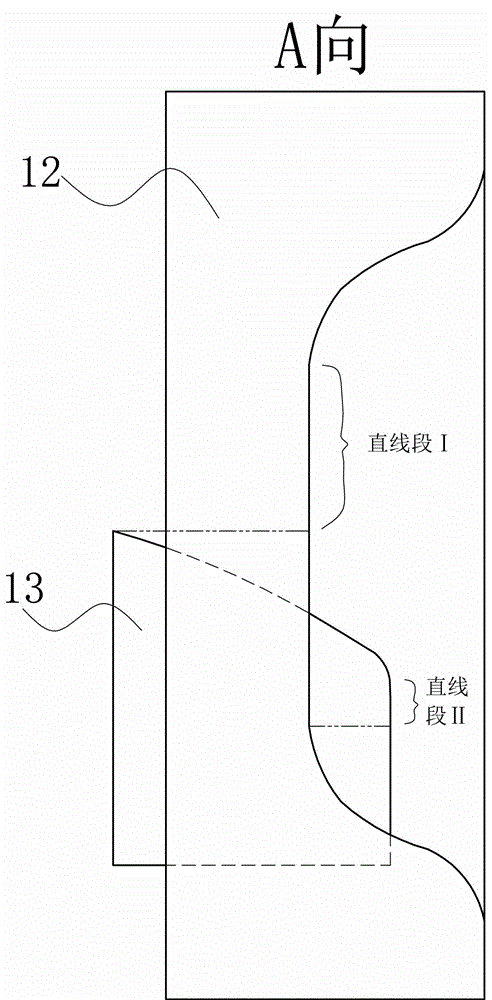

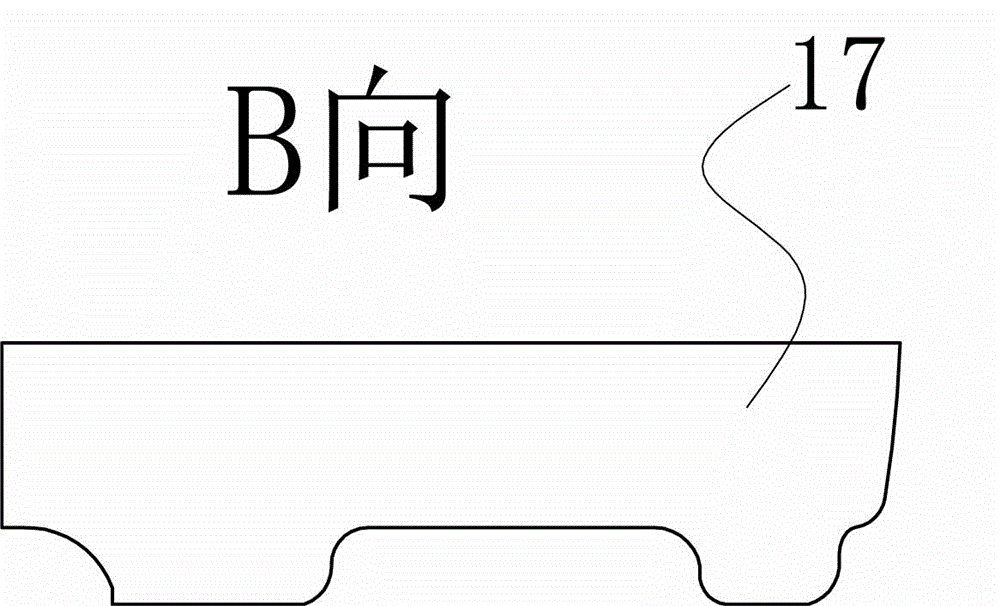

[0081] A mobile printing positioning conveying device, such as Figure 1-15 As shown, it includes a paper feeding device, a mobile mobile front positioning device, a circular side positioning device, a teeth moving device, a photoelectric distance measuring device 51, and a paper transfer roller 24;

[0082] Described paper feeding device comprises loose paper blowing nozzle 30, A component paper nozzle 25, B component paper nozzle 251, paper feeding nozzle 26, described loose paper blowing nozzle 30, A component paper nozzle 25 and B group Blow holes 252 are provided on the front side of the paper separating nozzle 251, and the paper loosening nozzle 30 is arranged on the left side of the A component paper nozzle 25 and the B component paper nozzle 251, and the A component paper nozzle 25 and B component paper nozzle 251 are installed on the same plane, and the described paper feeding nozzle 26 is arranged on the right side of A component paper nozzle 25 and B component paper...

Embodiment 2

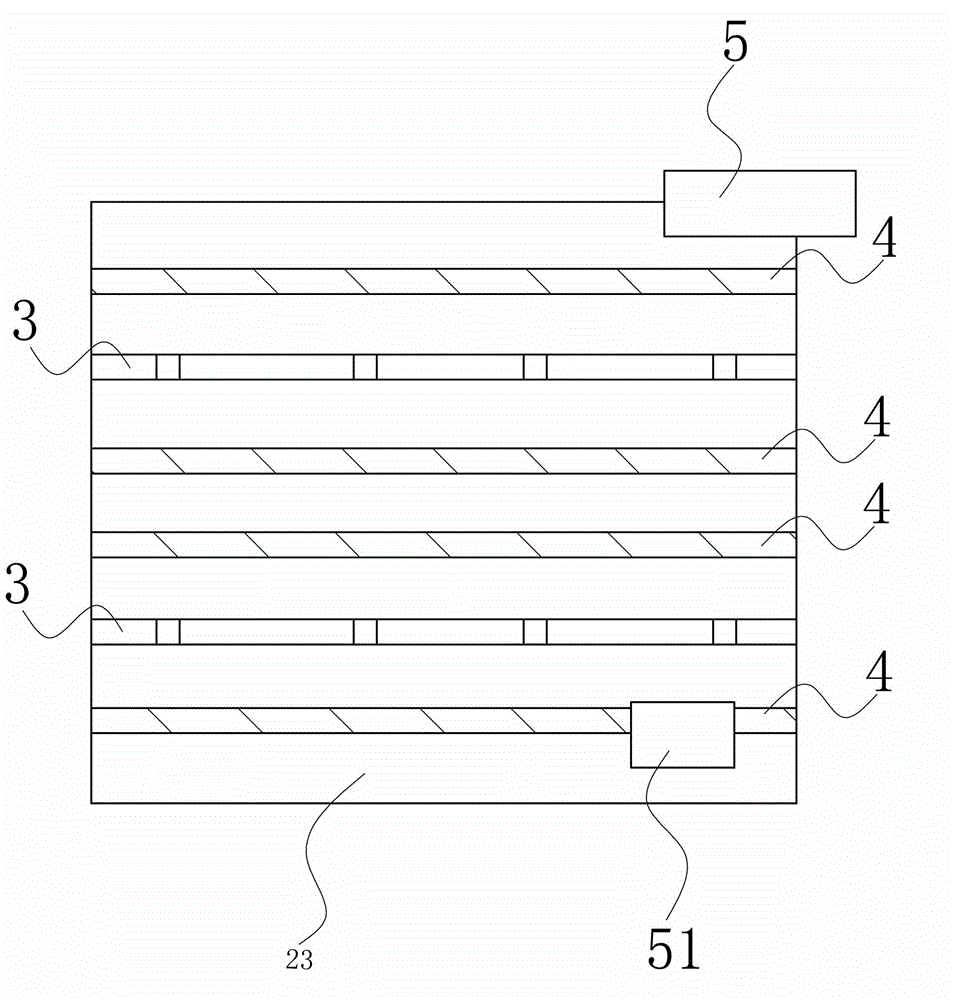

[0093] A mobile printing positioning conveying device, such as figure 1 with Figure 4 As shown in the figure, it includes a mobile movable front positioning device. The mobile mobile front positioning device includes a front gauge belt 3 and a paper feeding belt 4. The linear speed of the front gauge belt 3 is lower than that of the paper feeding belt. 4 line speed.

Embodiment 3

[0095] A mobile printing positioning conveying device, such as figure 1 , figure 2 with Figure 4 As shown, it includes a mobile front regulation positioning device. The mobile front regulation positioning device includes a front gauge belt 3 and a paper feeding belt 4. The linear speed of the front gauge belt 3 is lower than that of the paper feeding belt 4. .

[0096] The mobile front regulation positioning device also includes a paper feeding board 23 and a front regulation paper stopper 6, and the working surfaces of the front gauge line belt 3 and the paper feeding line belt 4 are located above the paper feeding board 23, The front gauge paper stopper 6 is installed on the front gauge line belt 3, and the front gauge paper stopper 6 and the paper transfer roller 24 act in unison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com