Patents

Literature

35results about How to "Improve paper feeding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

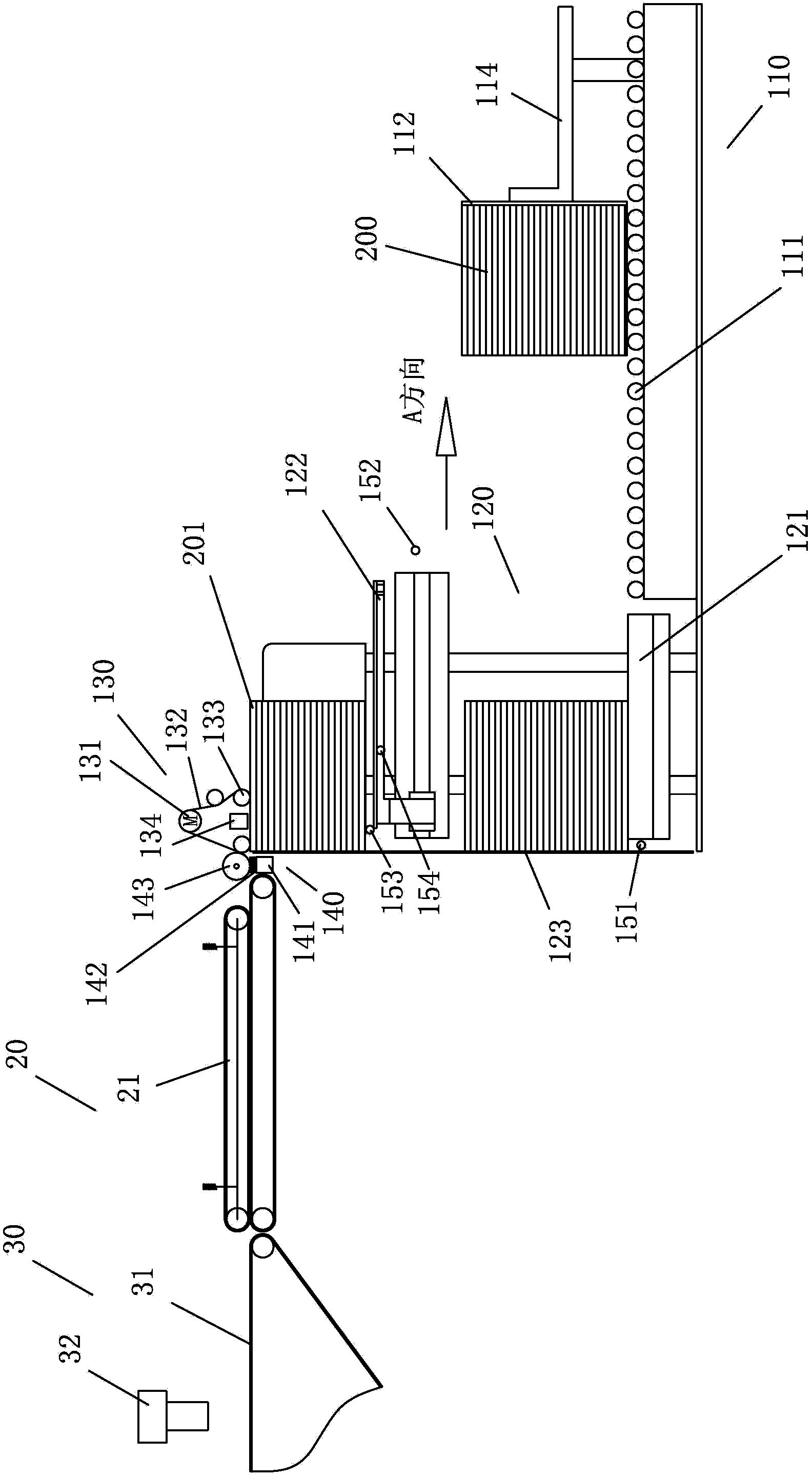

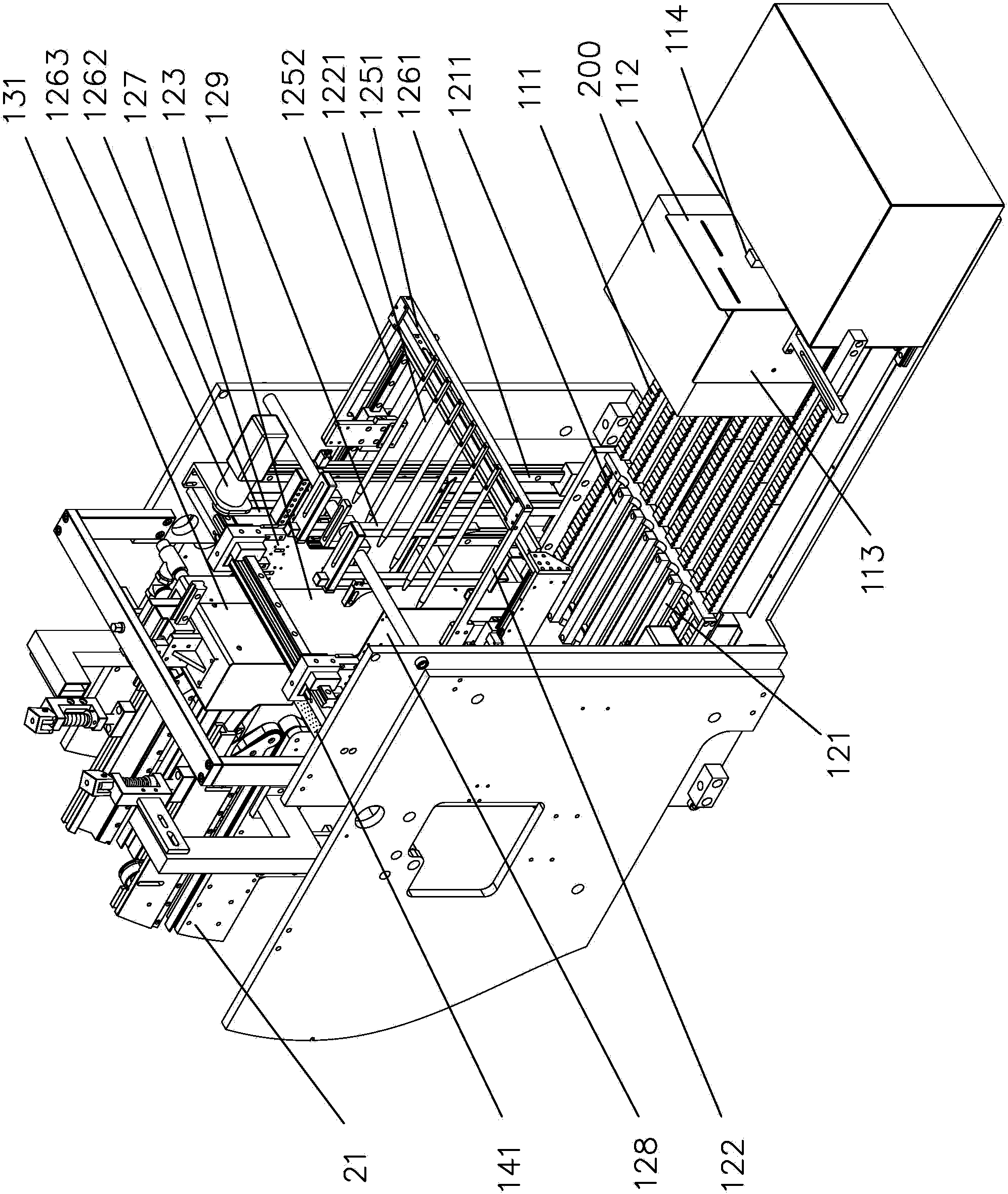

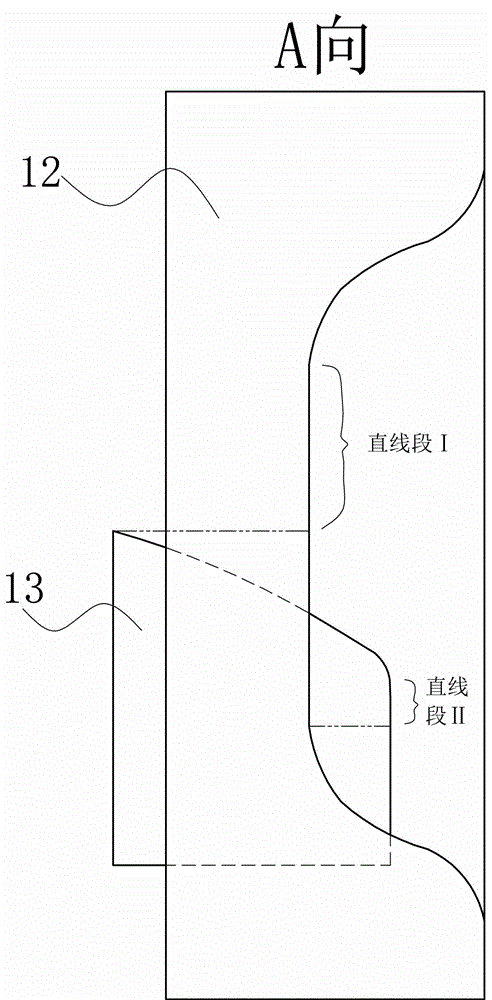

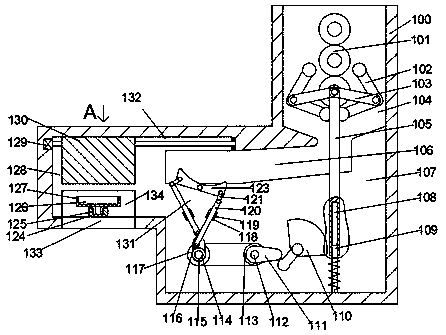

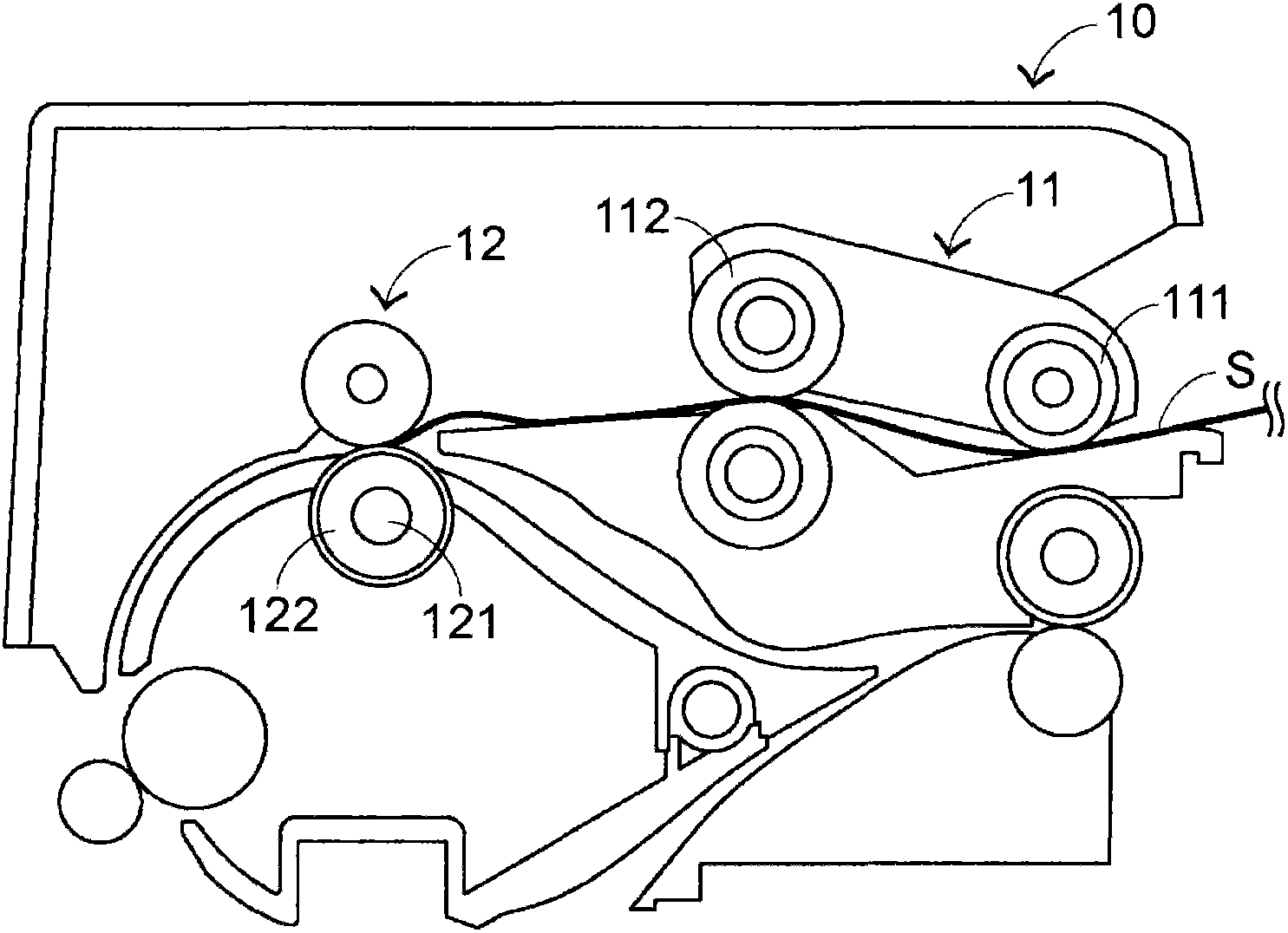

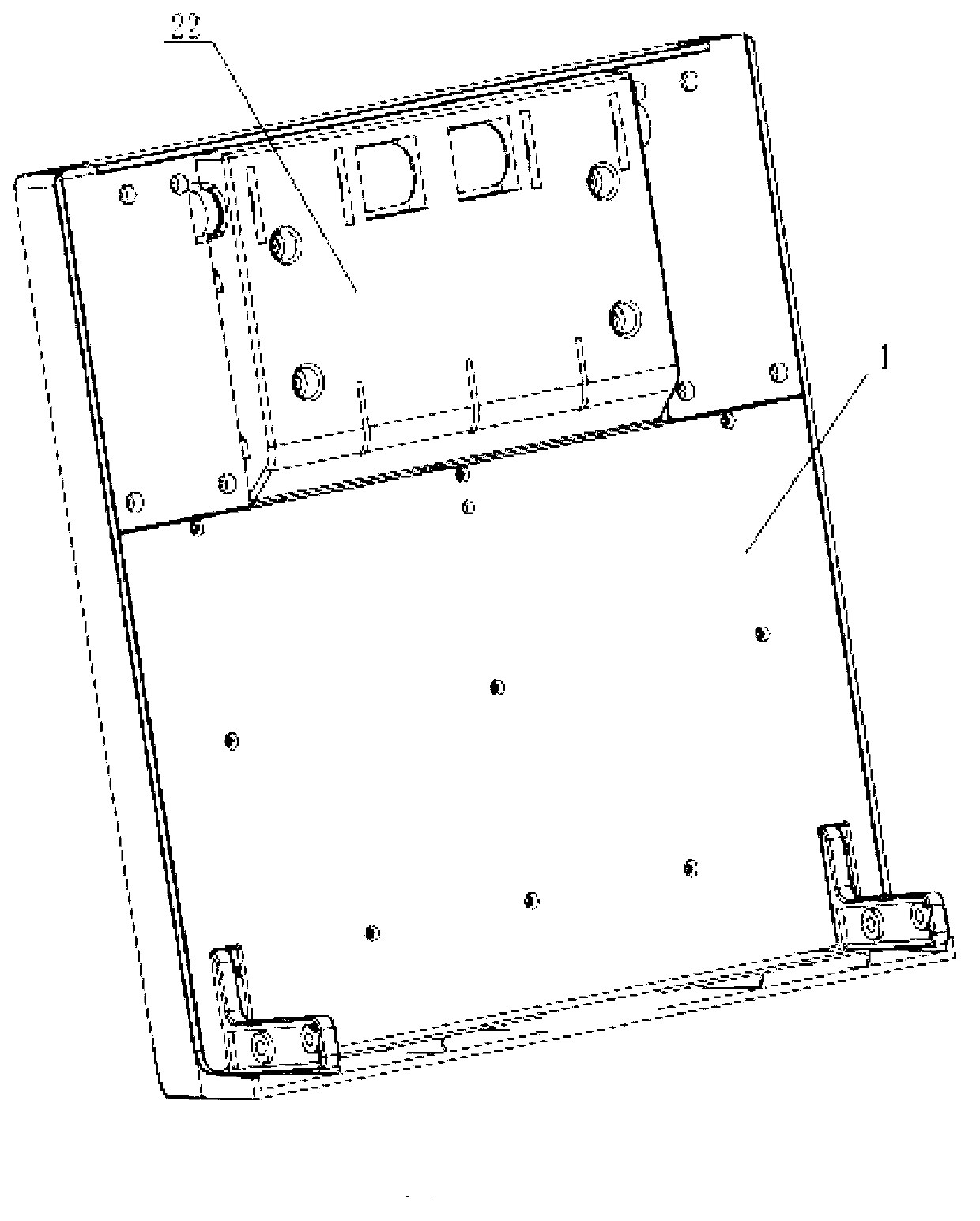

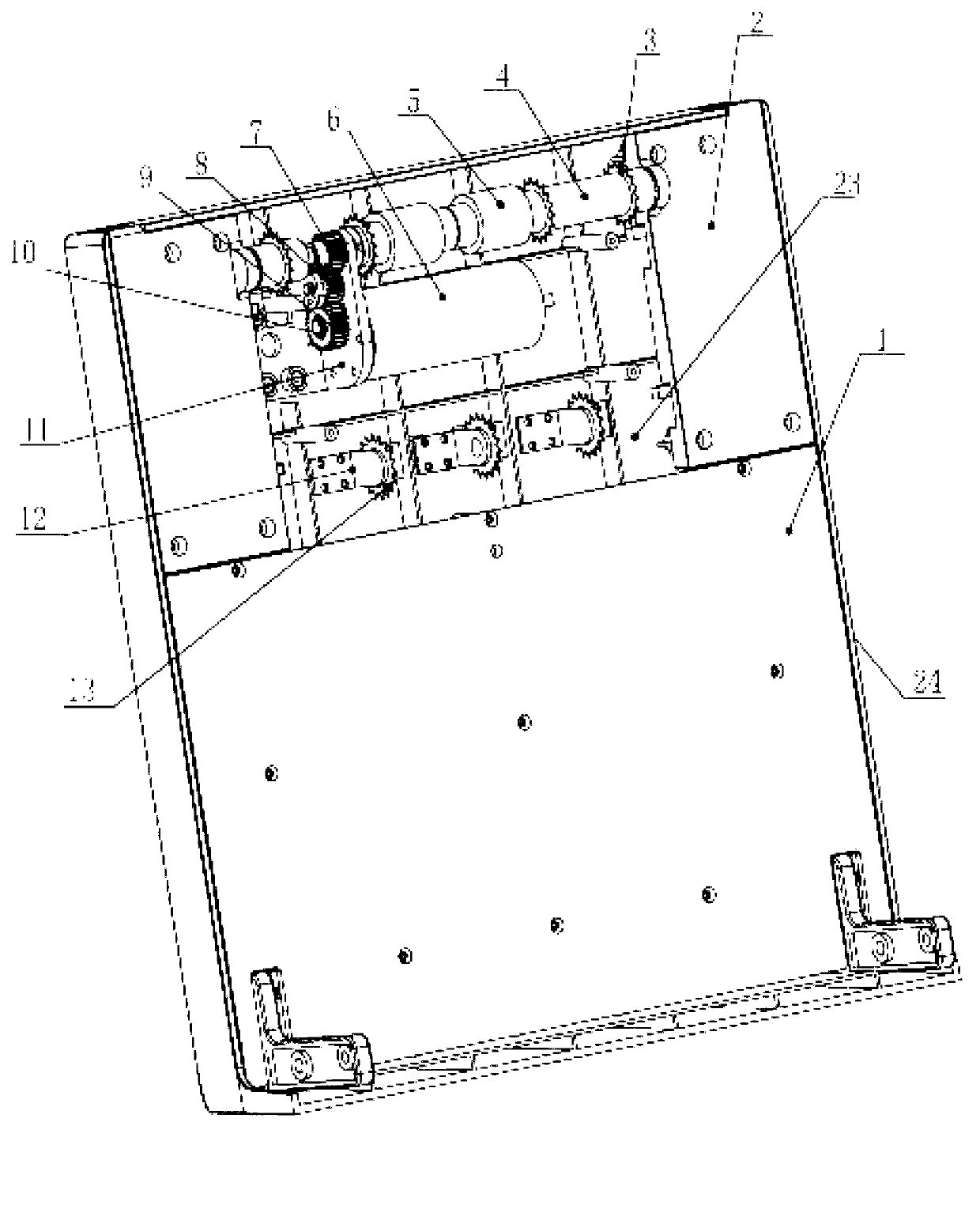

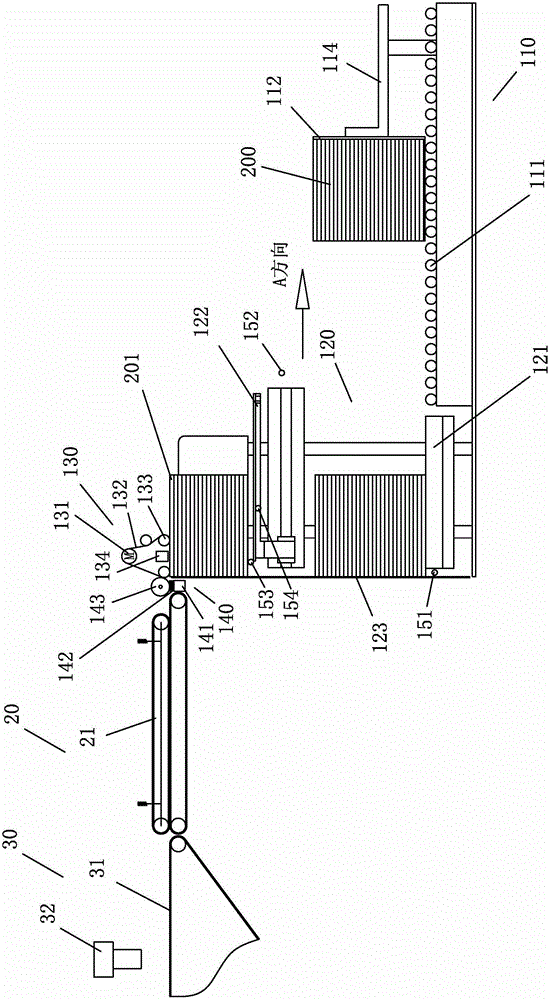

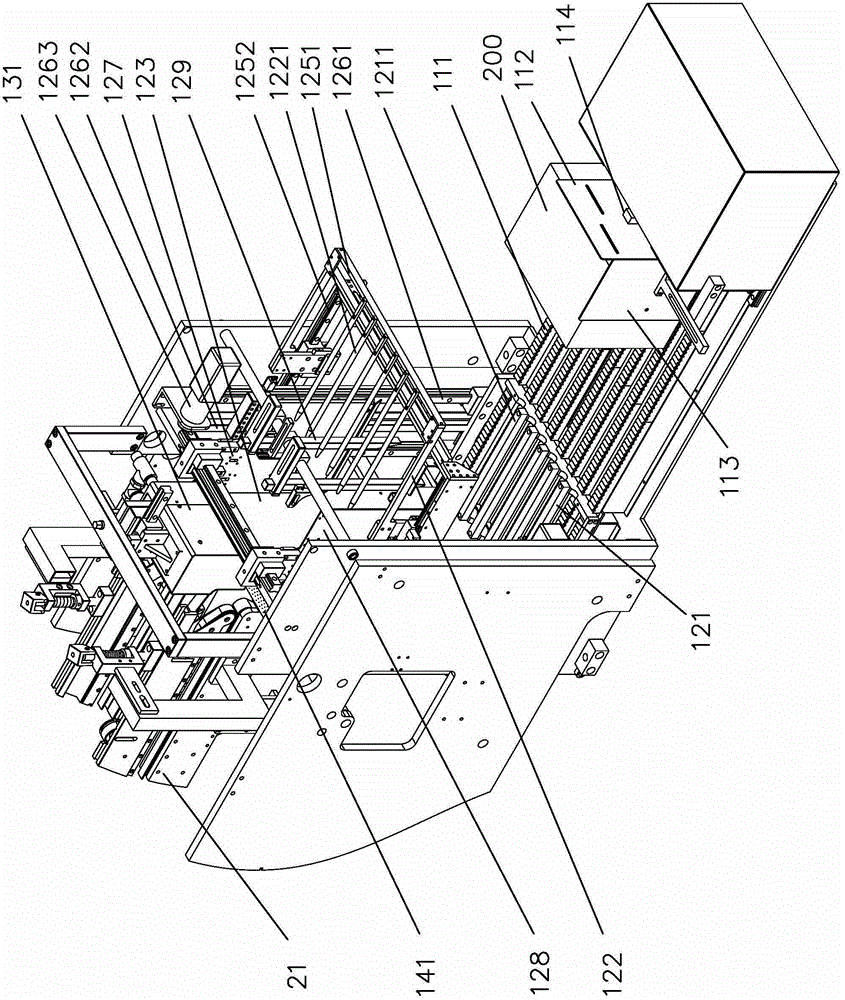

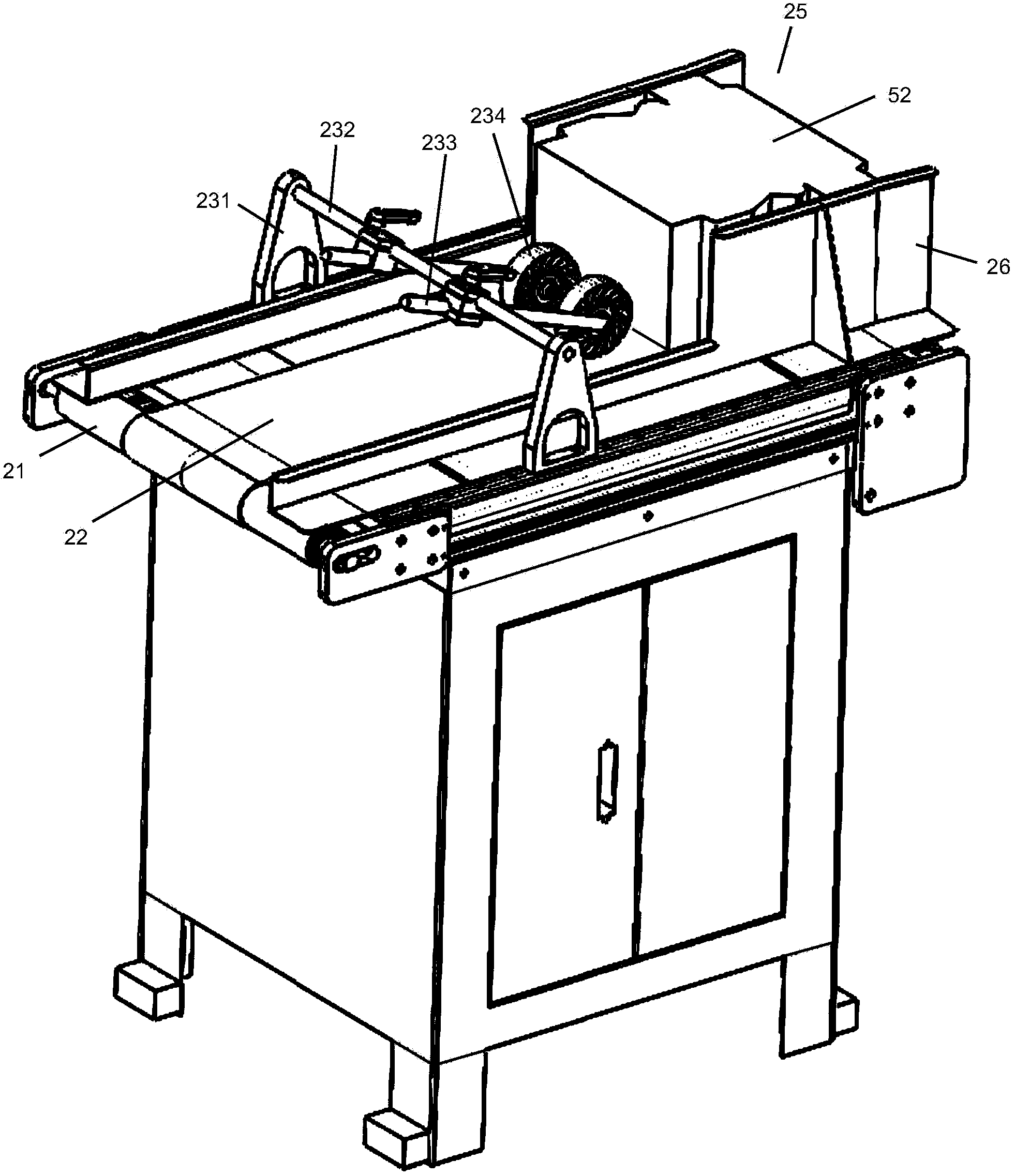

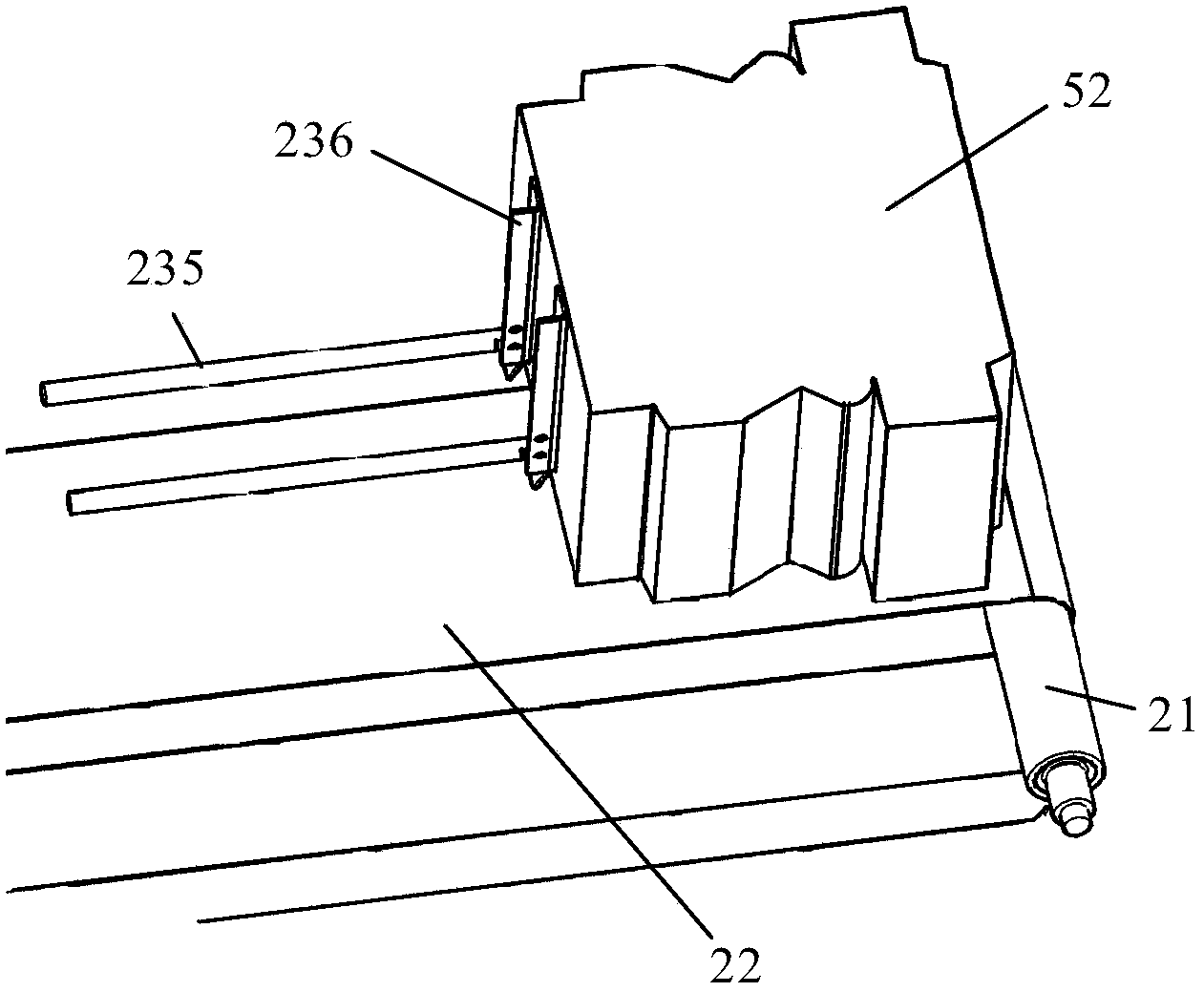

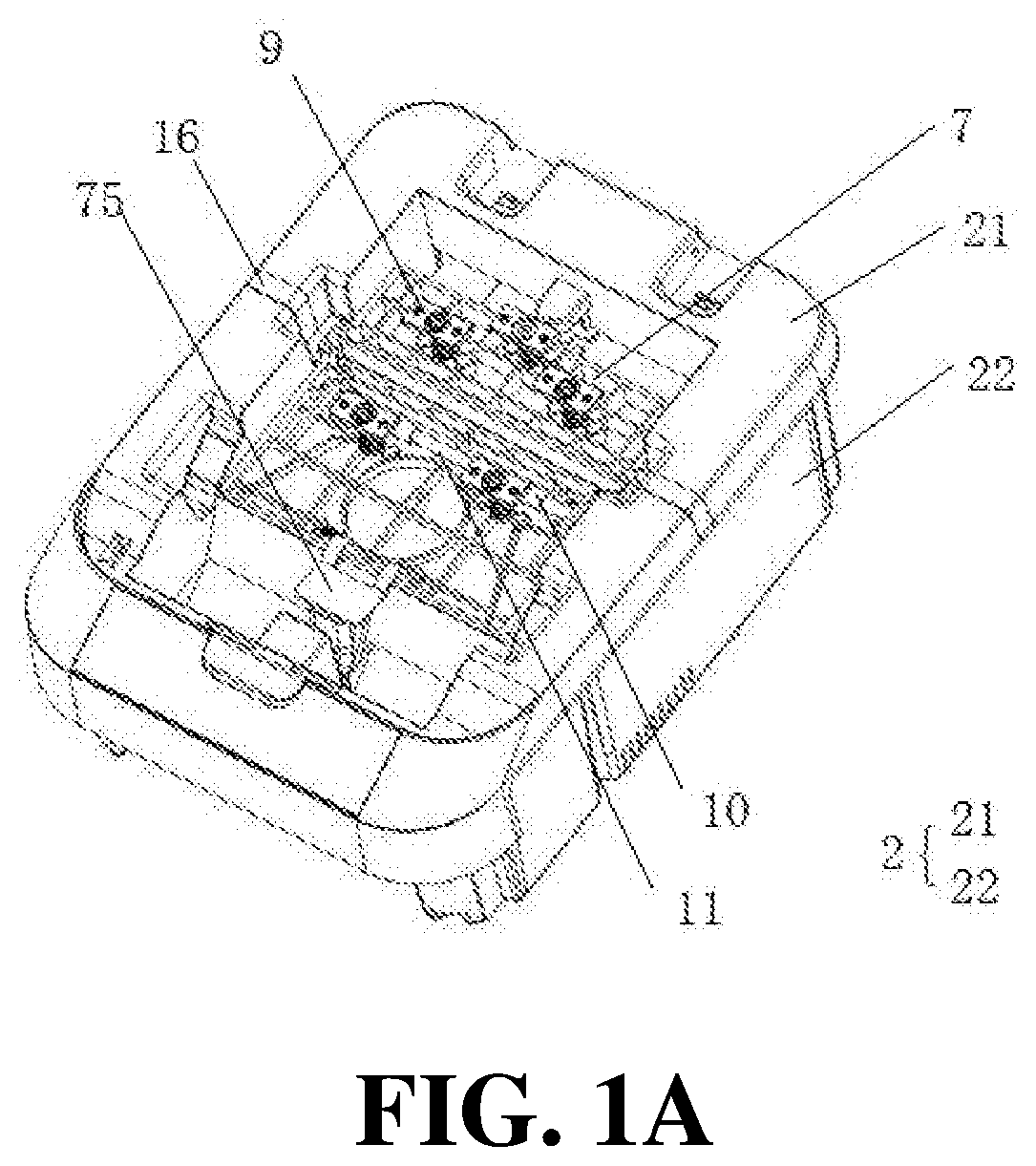

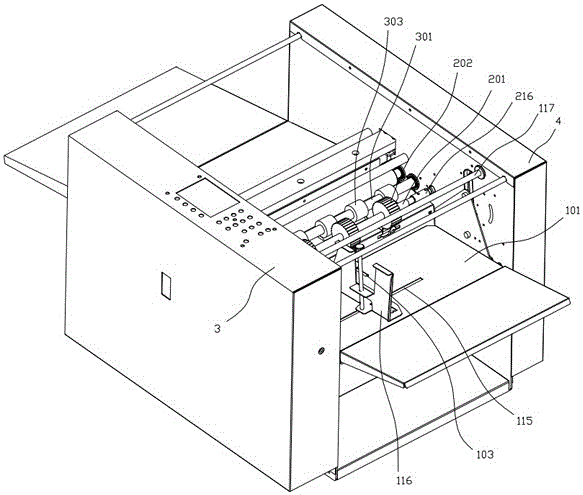

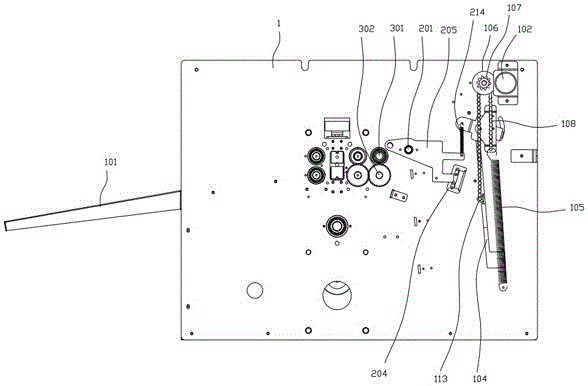

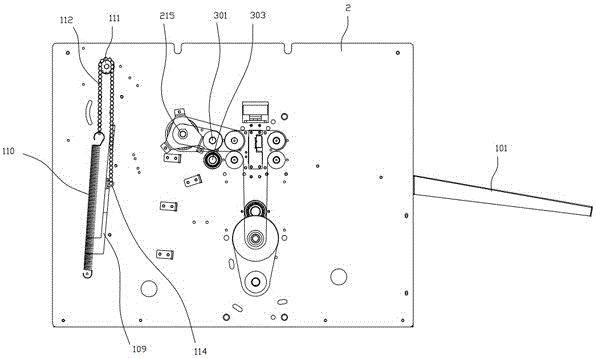

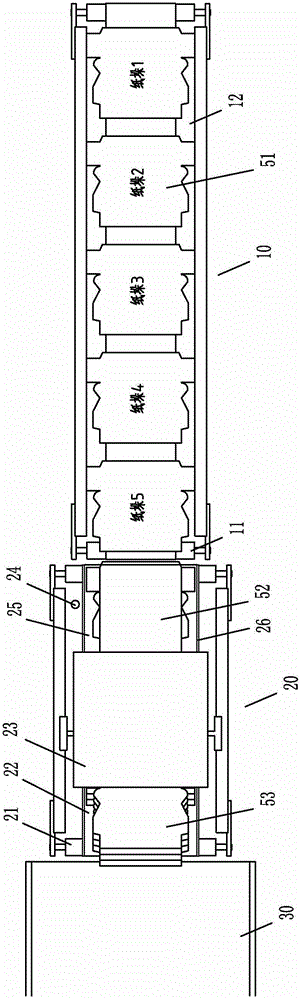

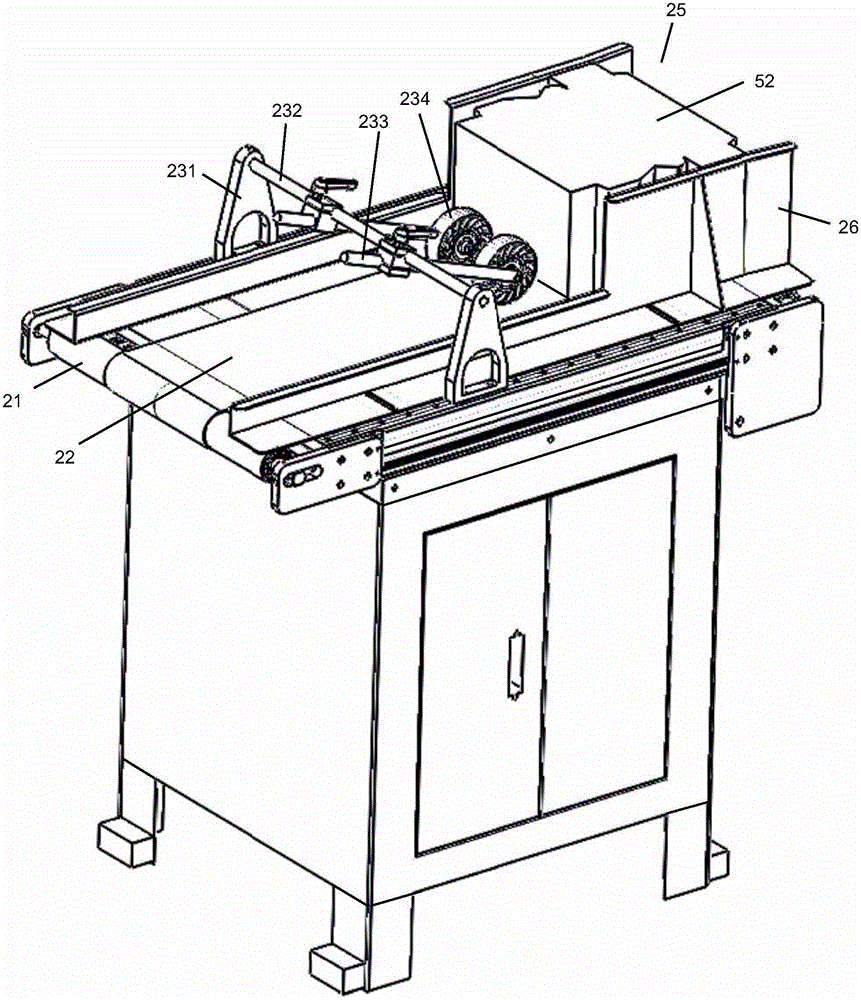

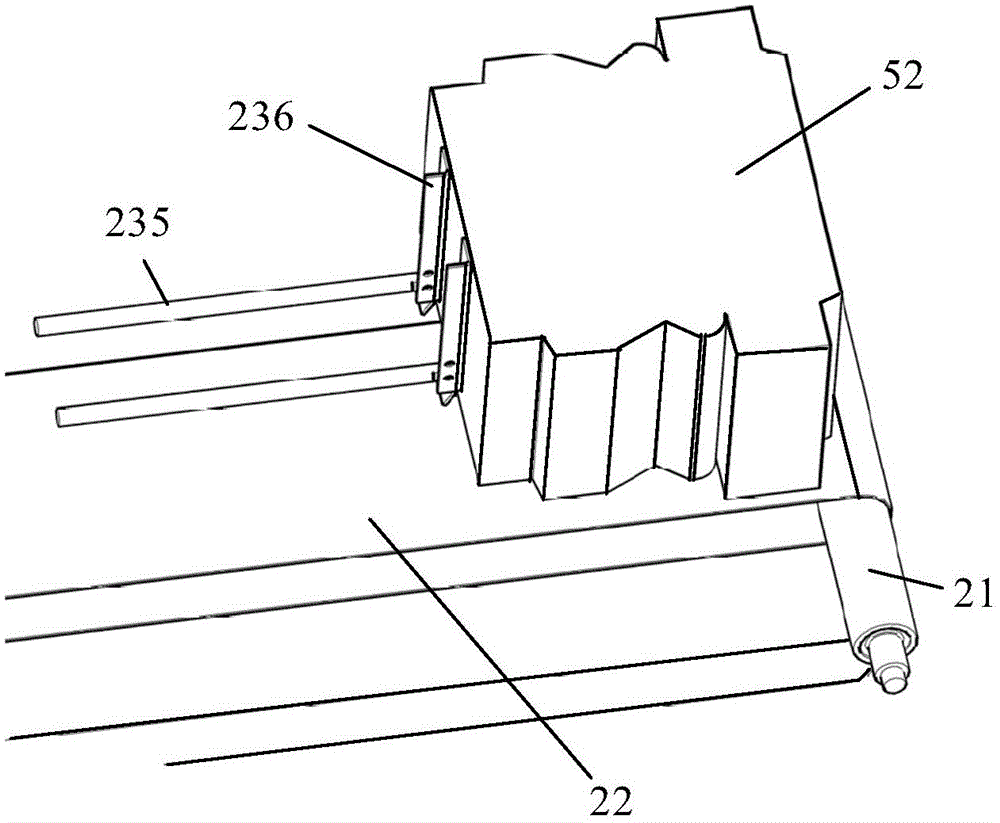

Paper feed machine for product check machine and paper feed method thereof

ActiveCN103787100AReduce or eliminate scratchesWon't breakArticle feedersArticle separationCardboardPaper machine

The invention discloses a paper feed machine for a product check machine and a paper feed method of the paper feed machine. The paper feed machine comprises an uninterruptible paper feed mechanism. An induced draft paper supply mechanism is correspondingly arranged above the upper paper outlet end of the uninterruptible paper feed mechanism. A paper aligning plate is vertically arranged on one side of the uninterruptible paper feed mechanism and corresponding to the output end of the induced draft paper supply mechanism. The output end of the induced draft paper supply mechanism and the input end of a blowing paper distributing mechanism are correspondingly arranged. The paper feed method includes the steps that a main paper feed table and an auxiliary paper feed table alternatively support and lift a printed matter stack with printing surfaces placed upwards; printed matter is uninterruptedly supplied to the induced draft paper supply mechanism; the induced draft paper supply mechanism continuously adsorbs a single sheet of printed matter from the position above the printed matter stack and transfers the single sheet of printed matter to the blowing paper distributing mechanism, and then the blowing paper distributing mechanism sends out the single sheet of printed matter after separating the single sheet of printed matter from the induced draft paper supply mechanism. By the adoption of the mode of adsorbing paper feed with the printing surfaces placed upwards, the single sheet of printed matter is uninterruptedly conveyed to a surface quality detector for surface quality detection, and therefore scratches of the printing surfaces of the printed matter are reduced or eliminated.

Owner:HEBEI TIANYUHENG TECH CO LTD

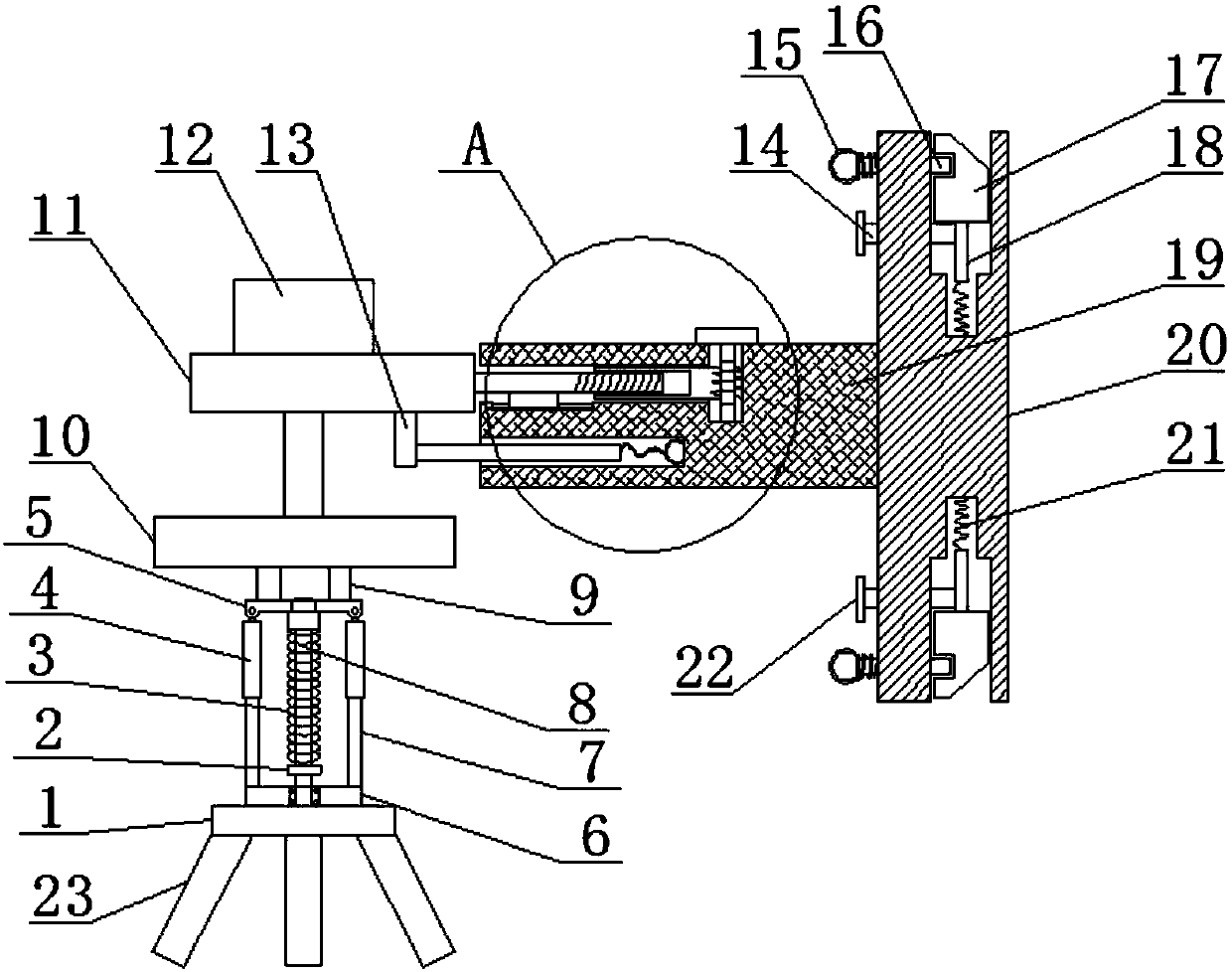

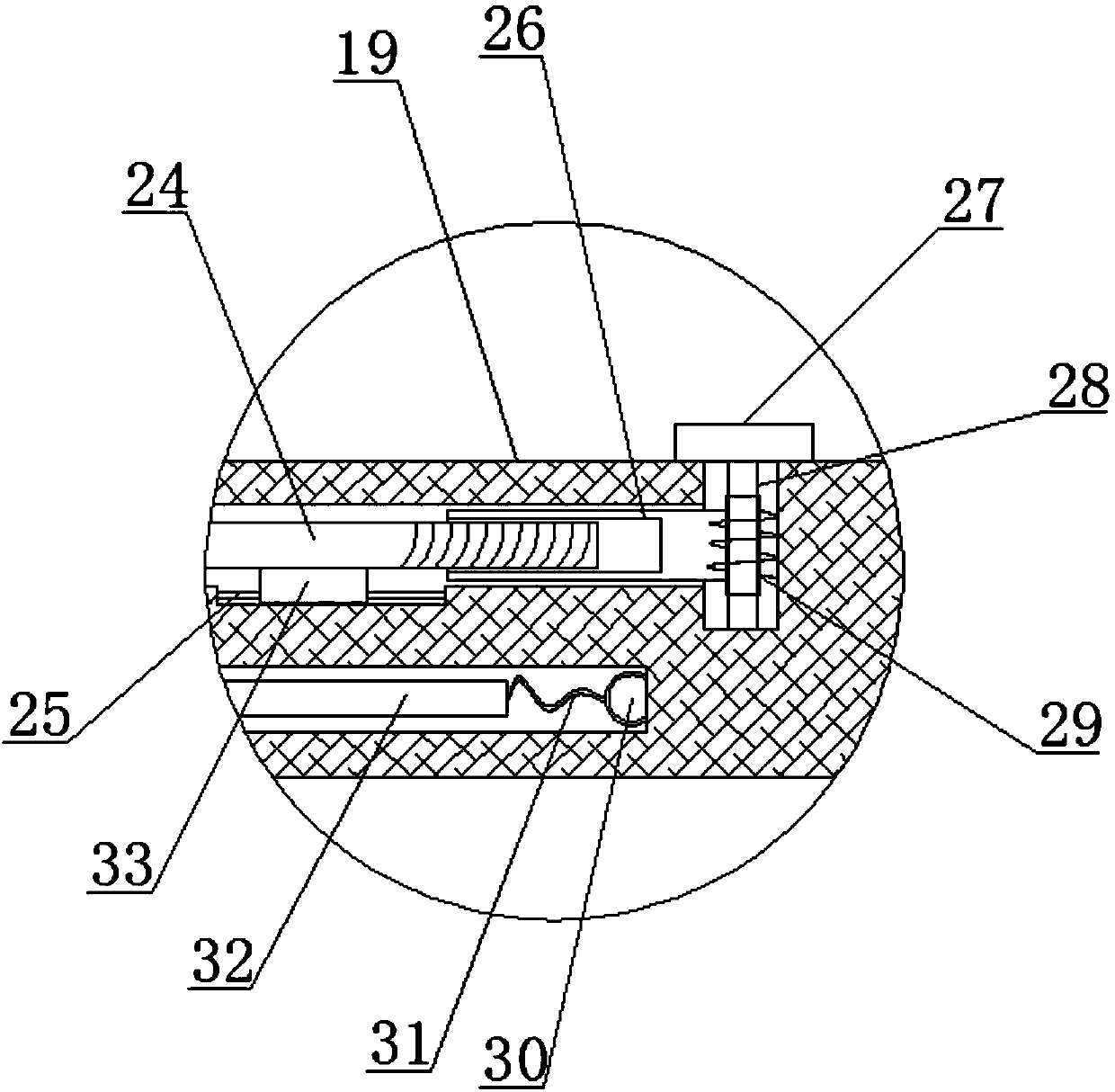

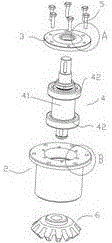

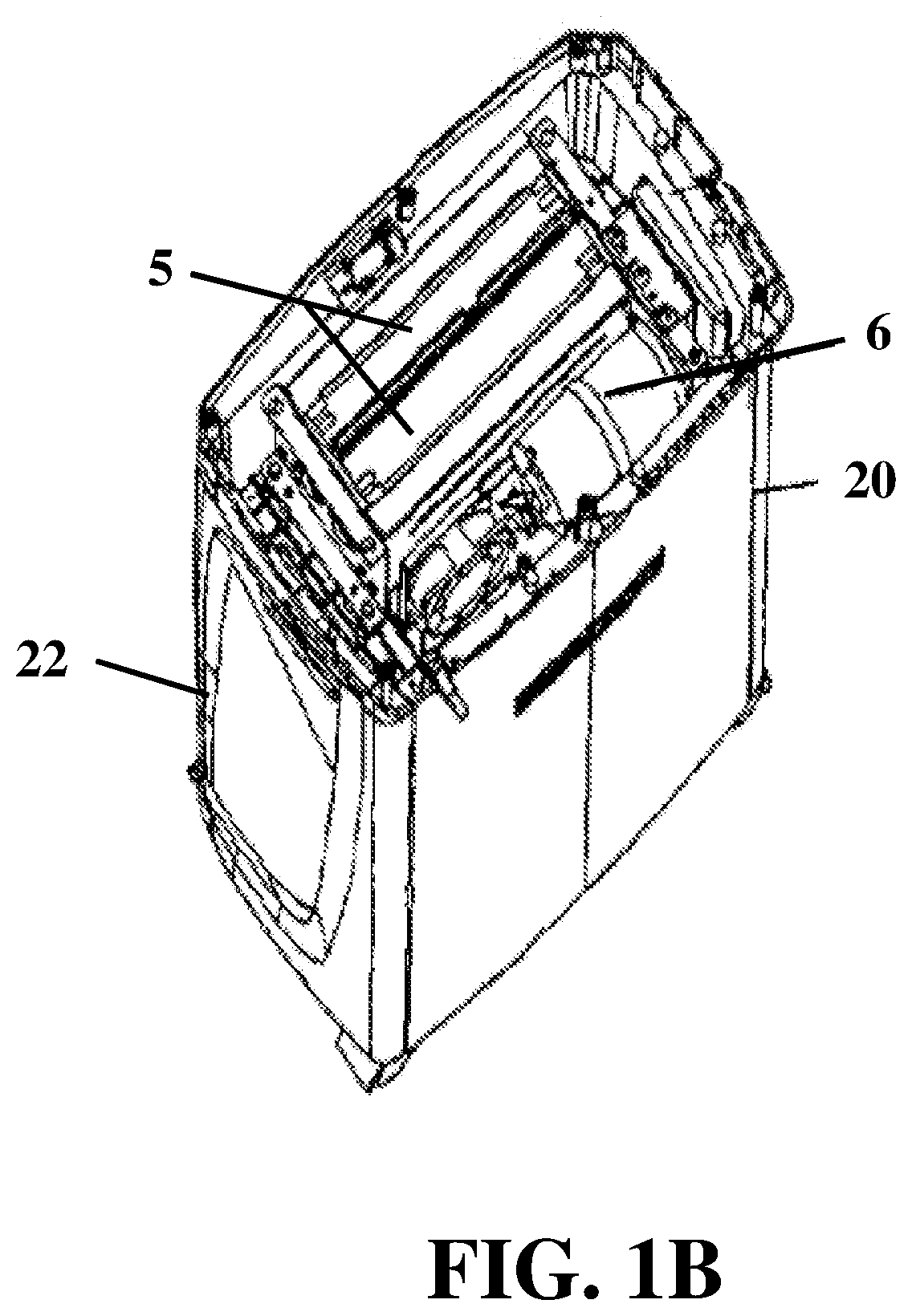

Mobile printing, positioning and conveying device

ActiveCN104692157AHigh speedShorten blowing timeArticle feedersPrinting press partsPaperboardEngineering

The invention relates to a printing device, in particular to a mobile printing, positioning and conveying device, and aims to provide a printing, positioning and conveying device which is long in positioning time, high in printing speed, high in overprinting accuracy and high in paper feeding speed. In order to solve the technical problem, the invention provides a mobile printing, positioning and conveying device which comprises a paper feeding device, a mobile front gauge positioning device, a circulation side gauge positioning device, an articulation tooth moving device, an electro-optical distance measurement device and a paper conveying roller. By virtue of the mobile printing, positioning and conveying device, the paper feeding efficiency can be improved; the paper moving distance can be accurately controlled by adjusting the distance between a movable cam and an annular fixed cam; the device is stable in structure, low in damage possibility and accurate to position; due to the cooperation of the circulation side gauge positioning device and a paper conveying plate, the paper positioning time can be prolonged; the printing speed is increased; the overprinting accuracy is ensured.

Owner:郭石生

Paper receiving device for corrugated paper board production line

ActiveCN108032558AImprove paper feeding efficiencyNot easy to oppressMechanical working/deformationProduction linePulp and paper industry

The invention discloses a paper receiving device for a corrugated paper board production line. The paper receiving device comprises a fixing plate; sliding grooves are formed in the upper end and thelower end of the fixing plate; inserting blocks are arranged in the two sliding grooves; limiting cavities are formed in the inner walls of the two sliding grooves; guide rods are arranged in the limiting cavities and are fixedly connected onto the inner walls of the limiting cavities through first elastic devices; one end, far away from the corresponding first elastic device, of each guide rod isfixedly connected onto the side wall of the corresponding inserting block; pulling rods are arranged on the side walls of the guide rods, penetrate through the inner walls of the sliding grooves andare movably connected with the fixing plate; a handle is arranged at one end, far away from the corresponding guide rod, of each pulling rod; inserting rods penetrate through the side wall of the fixing plate and are movably connected with the fixing plate; and inserting grooves corresponding to the inserting rods in position are formed in the side walls of the inserting blocks. The paper receiving device is reasonable in structural design, easy to operate, quick, reliable and not prone to slipping, the paper feeding efficiency for corrugated paper boards is greatly improved, and meanwhile, adisc head extrudes by the aid of a buffering mechanism and does not press the corrugated paper boards easily.

Owner:合肥宏图彩印有限公司

Paper feeder with device for collecting paper scraps and offcut during paper production

InactiveCN106743922AReduce workloadAvoid downtimeArticle deliveryWebs handlingPaper dustPaper production

The invention discloses a paper feeder with a device for collecting paper scraps and offcut during paper production. The paper feeder comprises a base plate, wherein a first mounting base and a second mounting base are oppositely arranged on the upper surface of the base plate; a first paper clamping roll set is arranged on the upper part of the first mounting base; a second paper clamping roll set is arranged on the upper part of the second mounting base. A third paper clamping roll set is arranged below a workbench of the paper feeder with the device for collecting the paper scraps and the offcut during the paper production, and the cut offcut enters the third paper clamping roll set through a paper discharging hole and then falls into a paper collecting box, so that shutdown caused by random accumulation of the offcut is avoided and the workload of an operator is reduced; an electrostatic box is arranged for adsorbing and collecting the paper scraps attached to the upper surface of paper, and brushes on a drum constantly generate friction with a plastic plate to form electrostaticity so as to adsorb the paper scraps, so that in the next process, a defective product caused by attachment of the paper scraps is avoided; the paper feeder is simple in structure, convenient to use and high in paper feeding efficiency.

Owner:刘发民

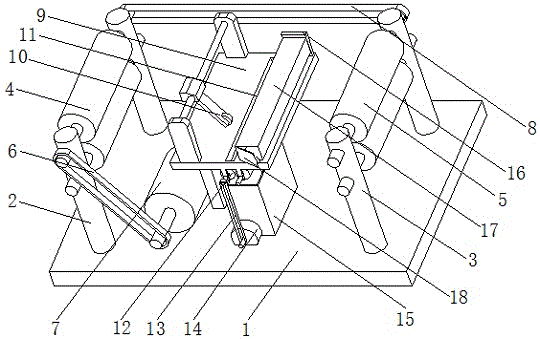

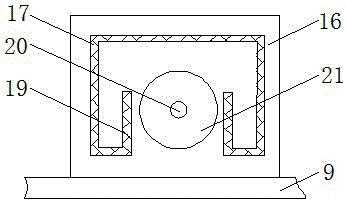

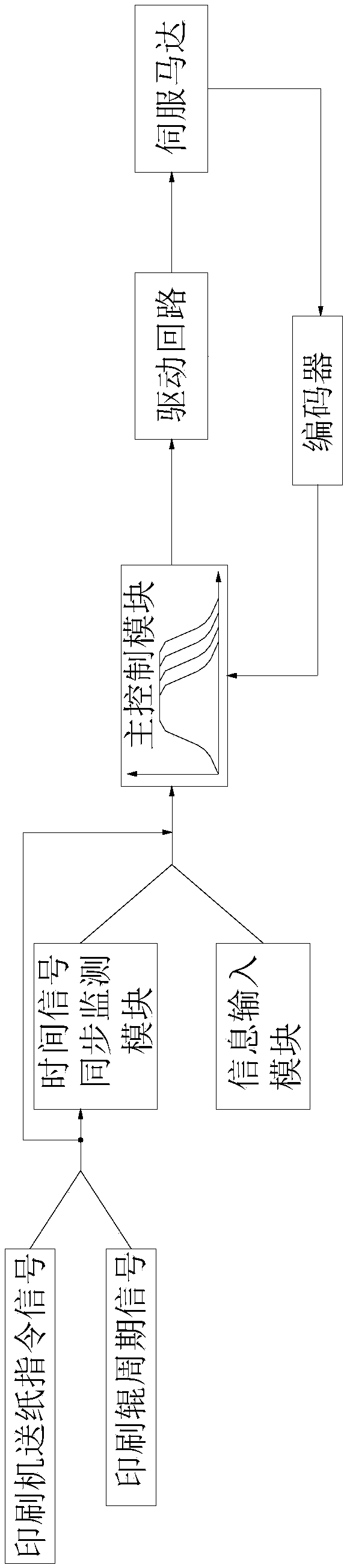

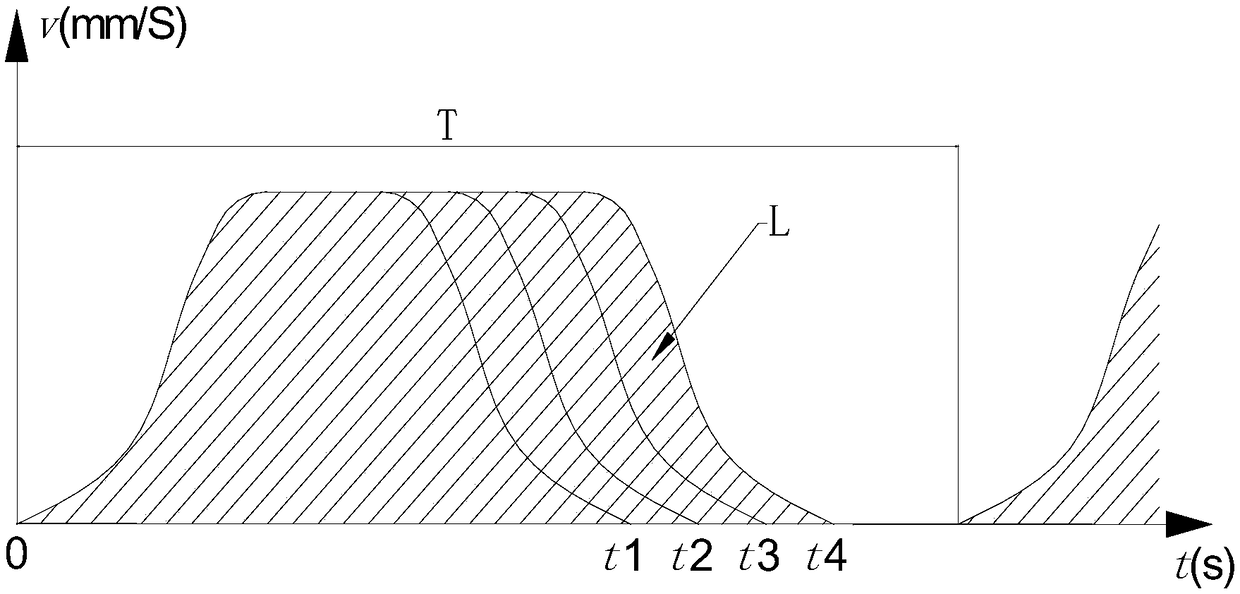

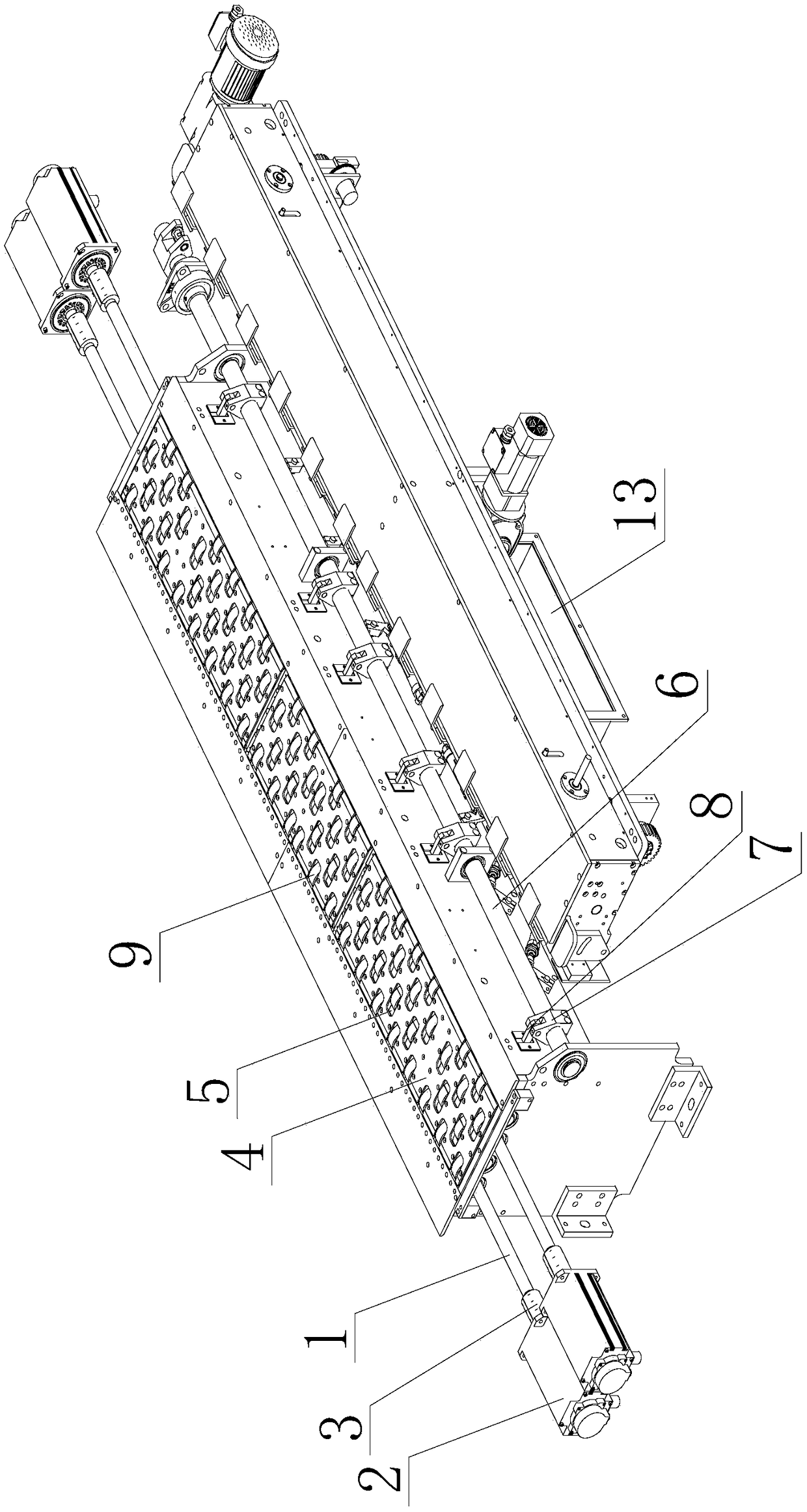

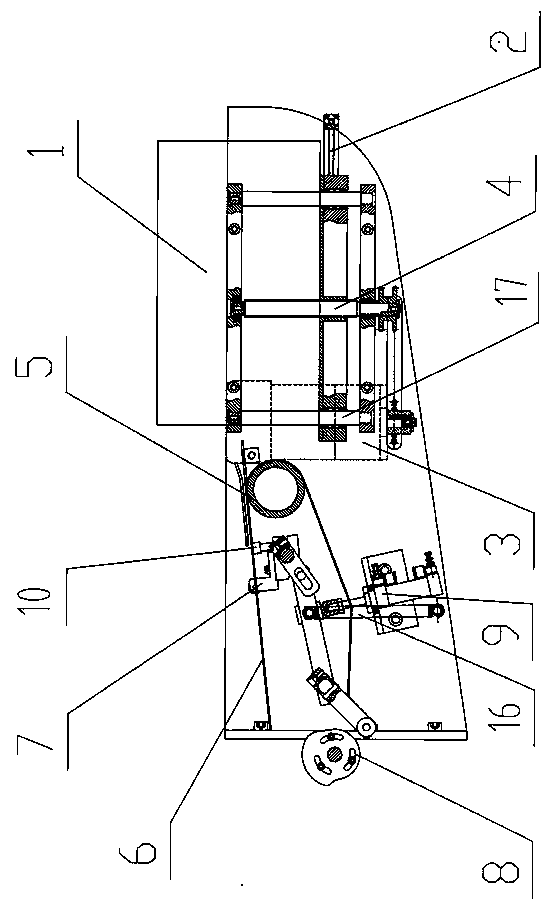

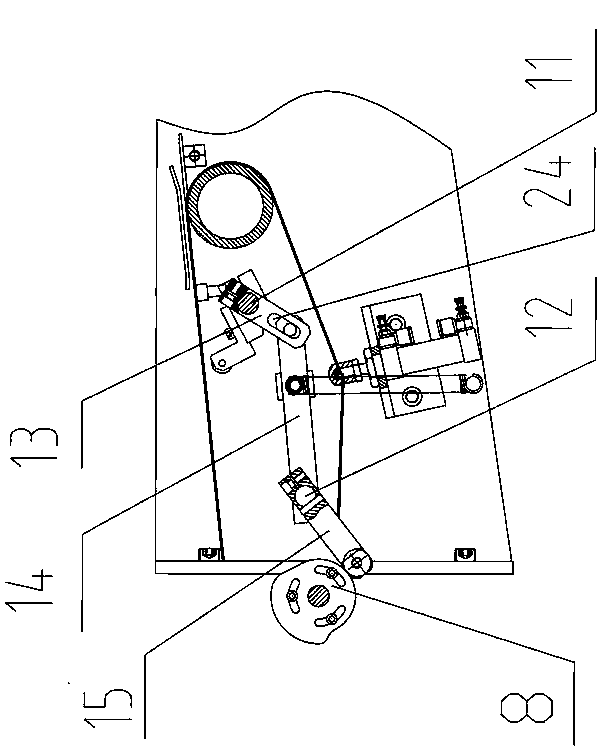

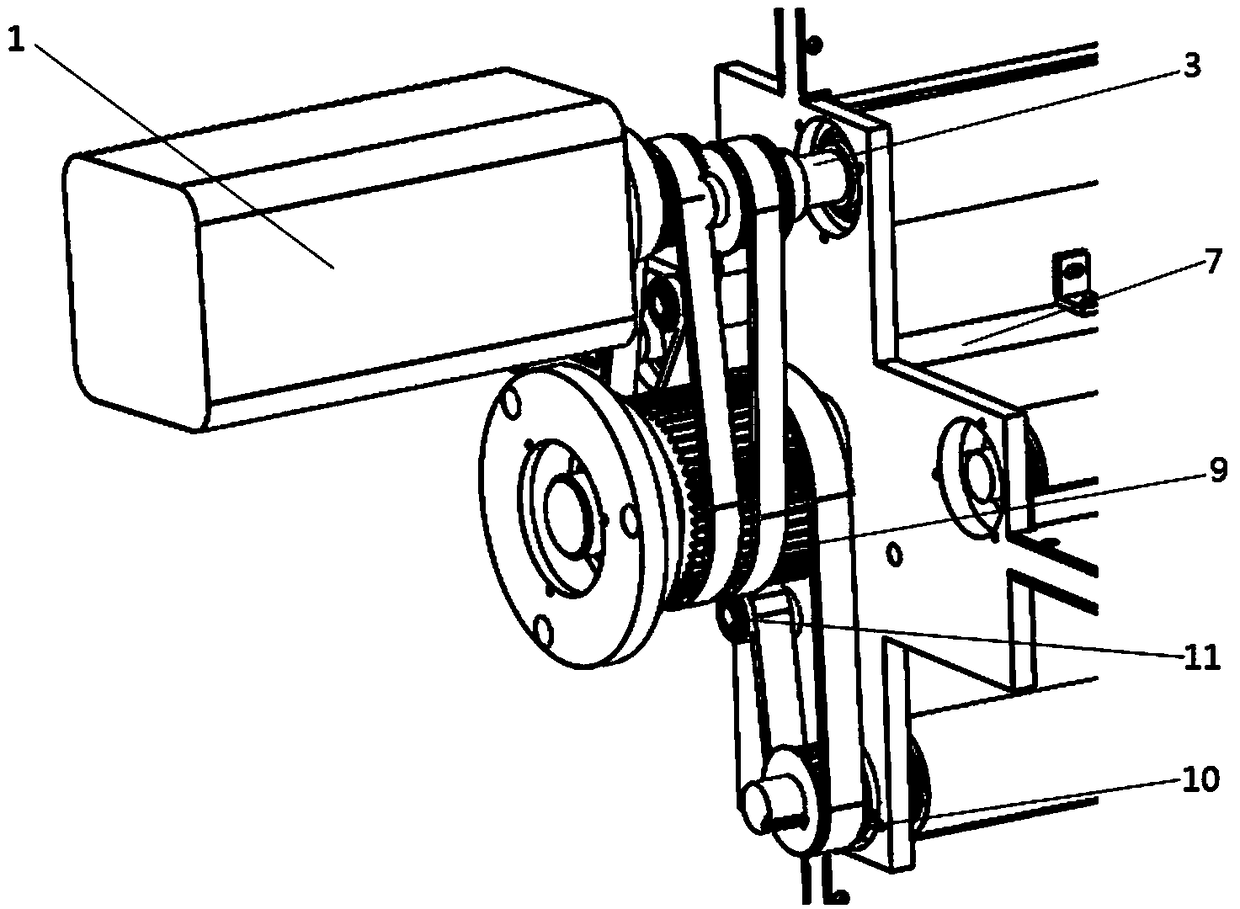

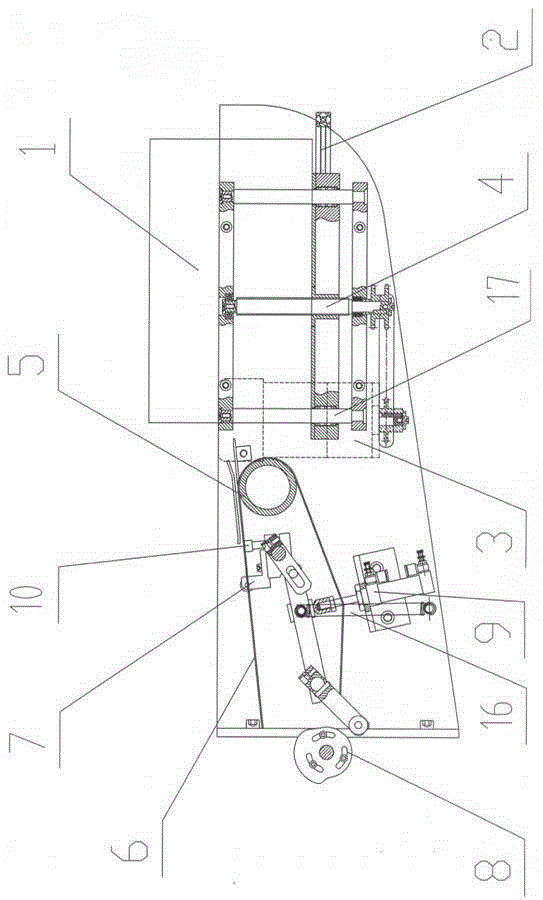

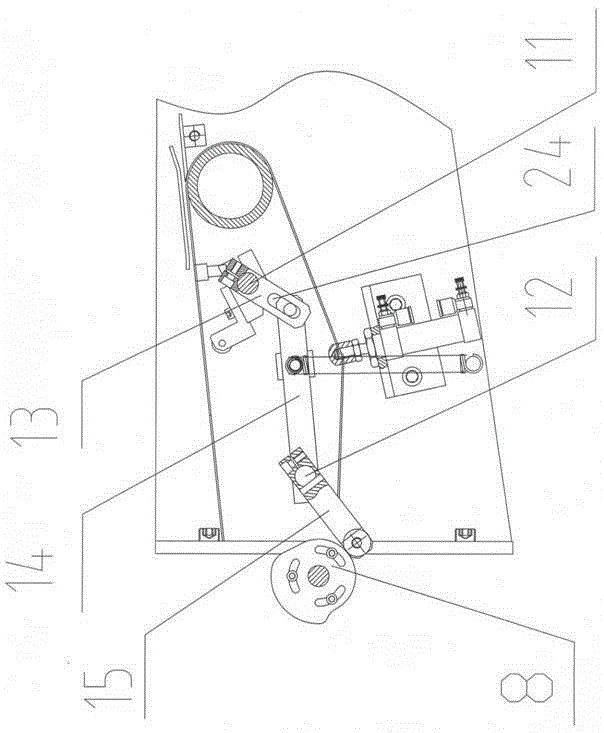

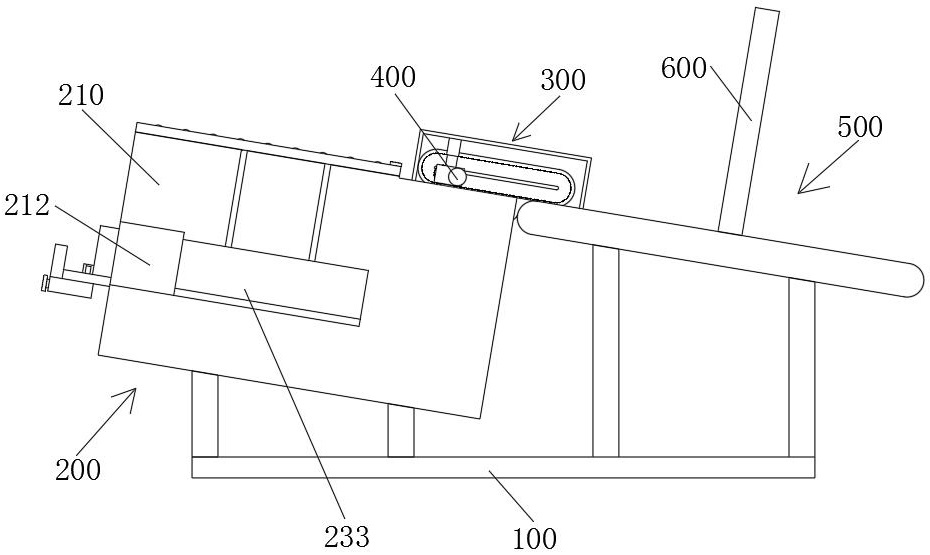

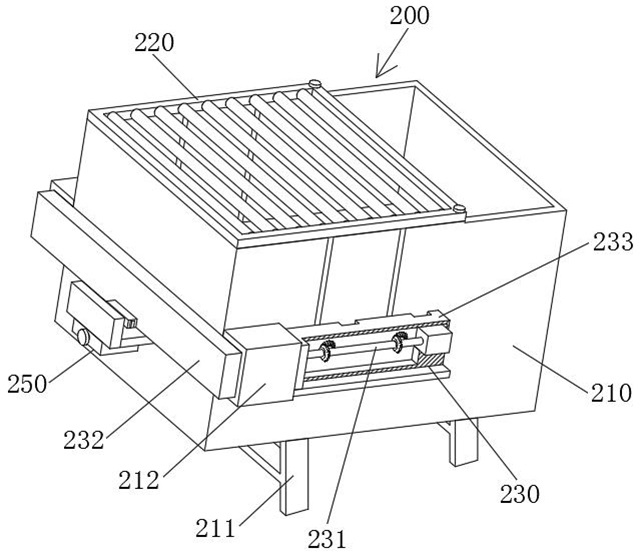

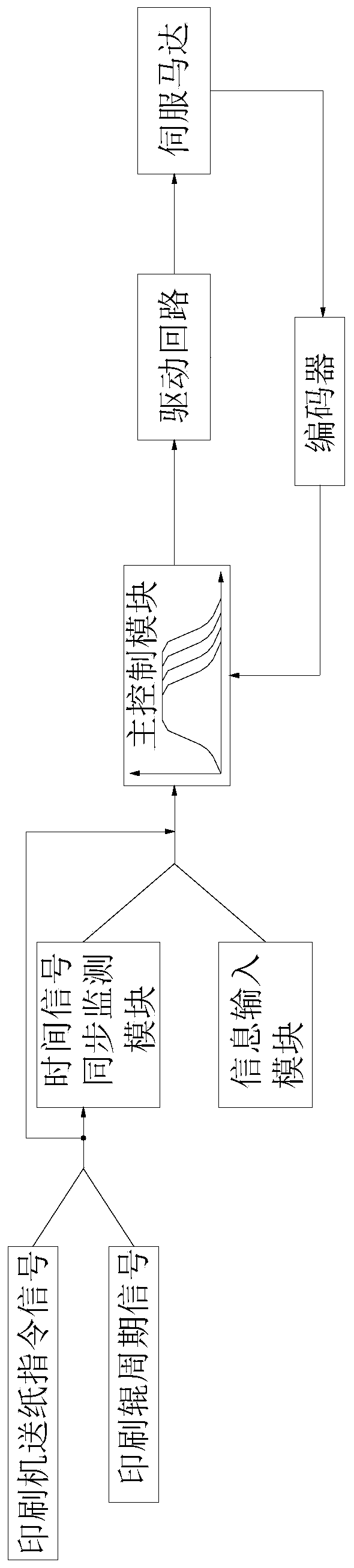

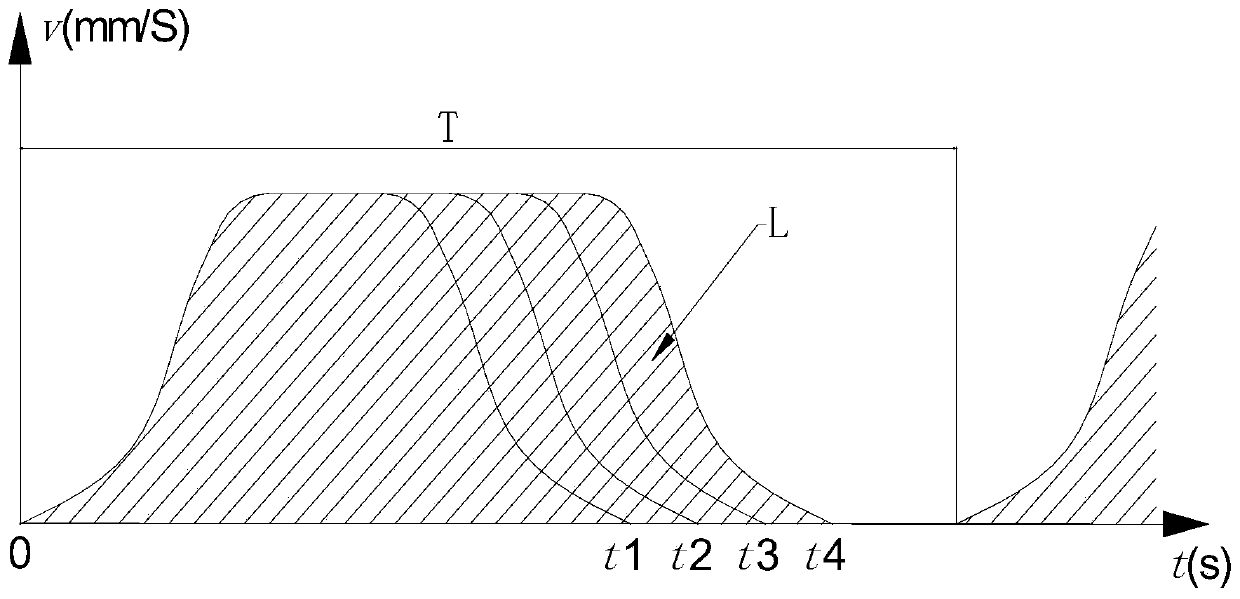

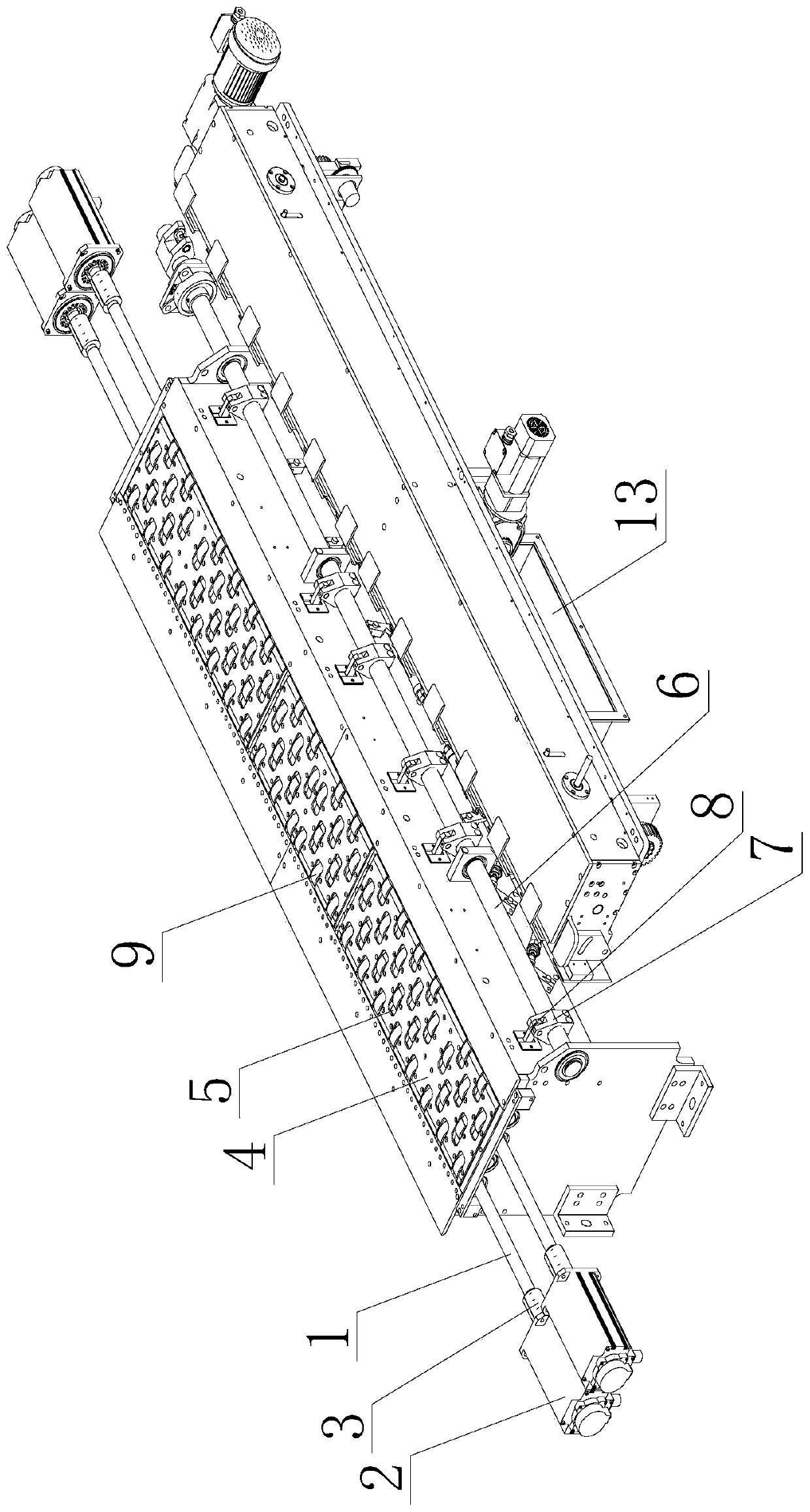

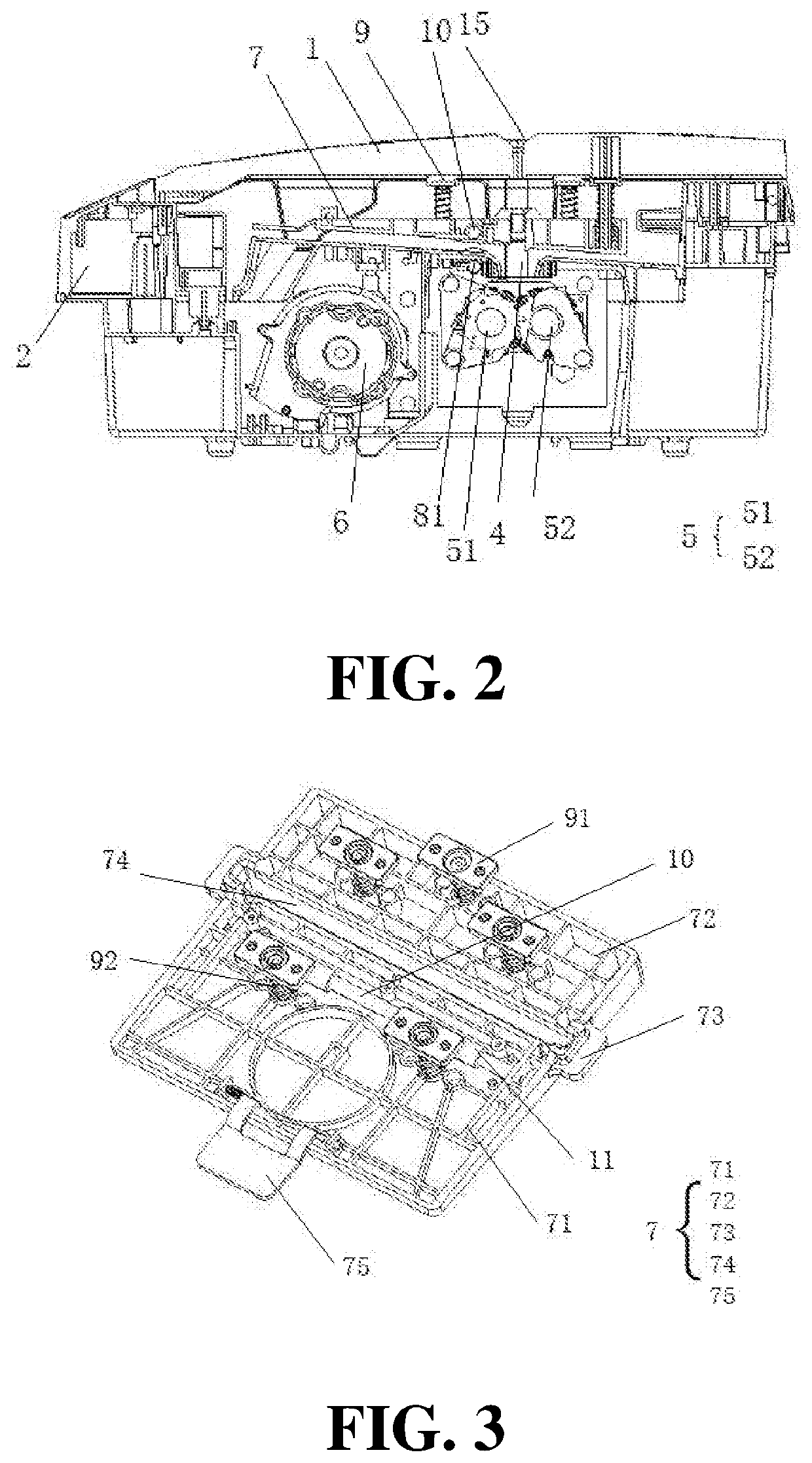

Front edge paper feed portion for corrugated paper printing equipment and drive device of front edge paper feed portion

ActiveCN108819470AOvercoming the problem of not being able to start and stop quicklyPaper feeding speedPrinting press partsArticle separationTime signalFront edge

The invention discloses a front edge paper feed portion of corrugated paper printing equipment and a drive device of the front edge paper feed portion. The drive device comprises servo motors, couplings and a master control device. Each paper feed shaft in the front edge paper feed portion is correspondingly provided with the corresponding servo motor, each servo motor is connected with the corresponding paper feed shaft through the corresponding coupling, and the servo motors are connected with the master control device. A time signal synchronous monitoring module, an information input module, a master control module, a drive loop and an encoder are arranged in the master control device. The front edge paper feed portion is provided with the drive device and comprises a paper feed platform and a lifting plate lifting mechanism. A lifting plate on the paper feed platform is driven through the lifting plate lifting mechanism to do lifting motion, and the paper feed shafts are driven bythe servo motors to complete paper feed. Or, the front edge paper feed portion comprises the paper feed platform and a paper supporting mechanism, and through lifting motion of the paper supporting mechanism, the paper feed shafts are driven by the servo motors to complete paper feed. According to the front edge paper feed portion of the corrugated paper printing equipment and the drive device ofthe front edge paper feed portion, the paper feed speed can be greatly improved, and the problem that a traditional paper feed device cannot be started or stopped rapidly is effectively solved.

Owner:GUANGZHOU KESHENGLONG CARTON PACKING MACHINE

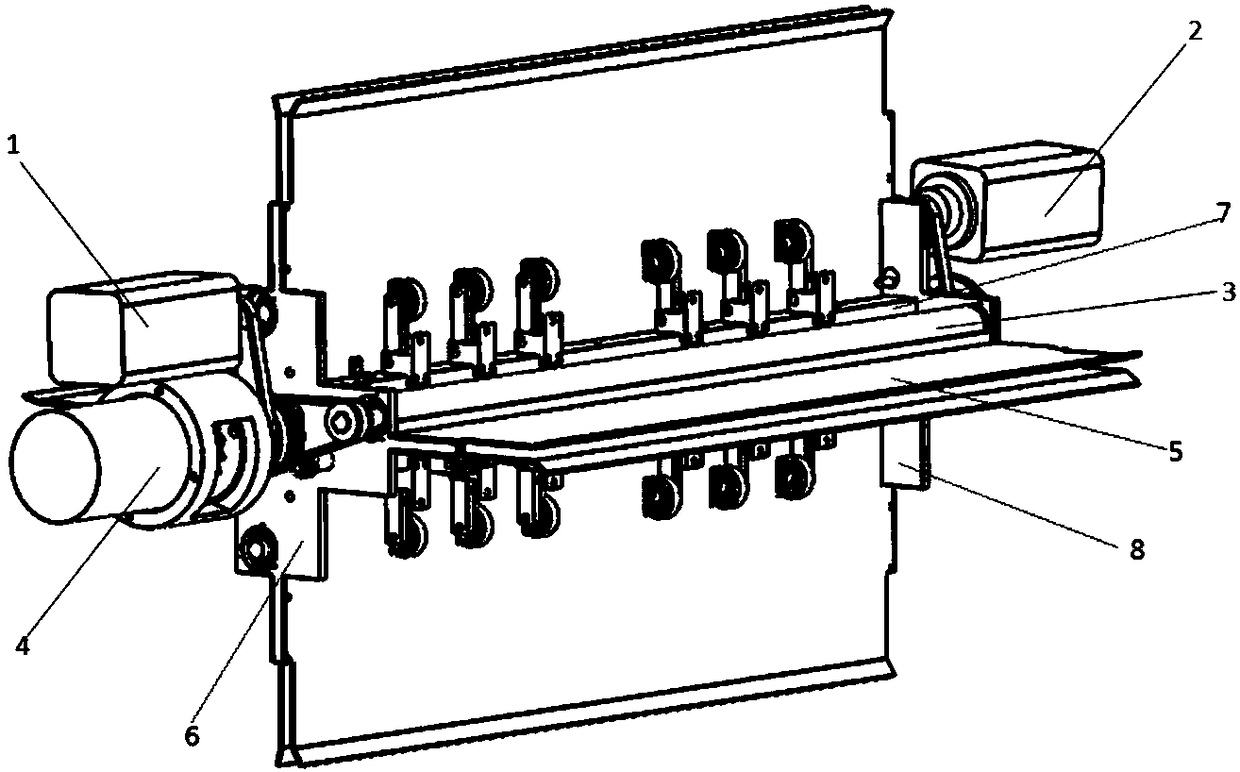

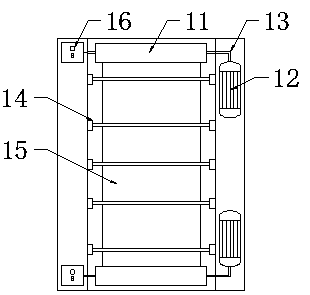

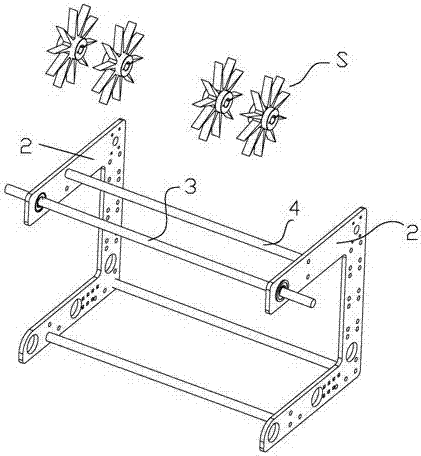

Paper feeding mechanism of paperboard pasting machine

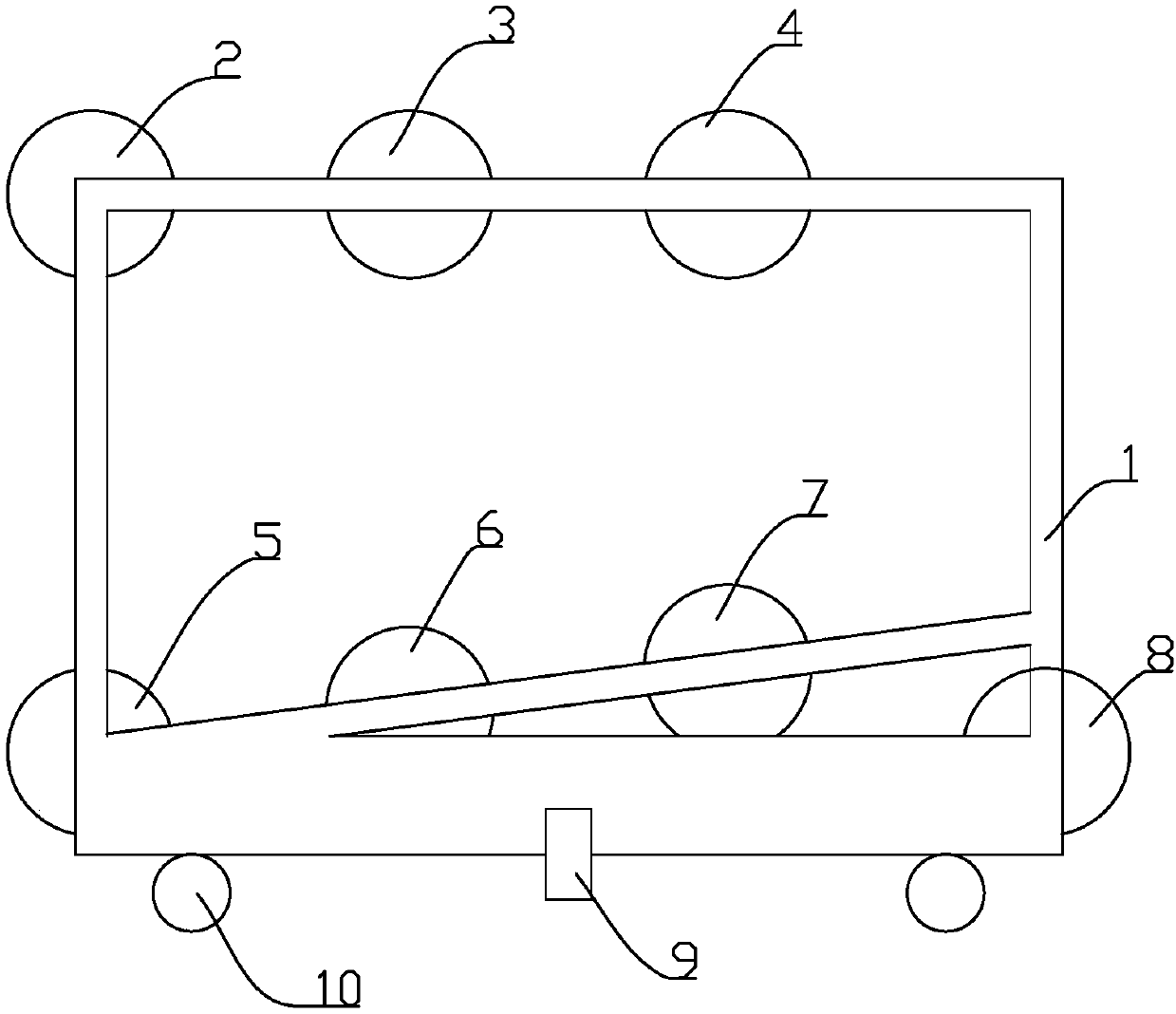

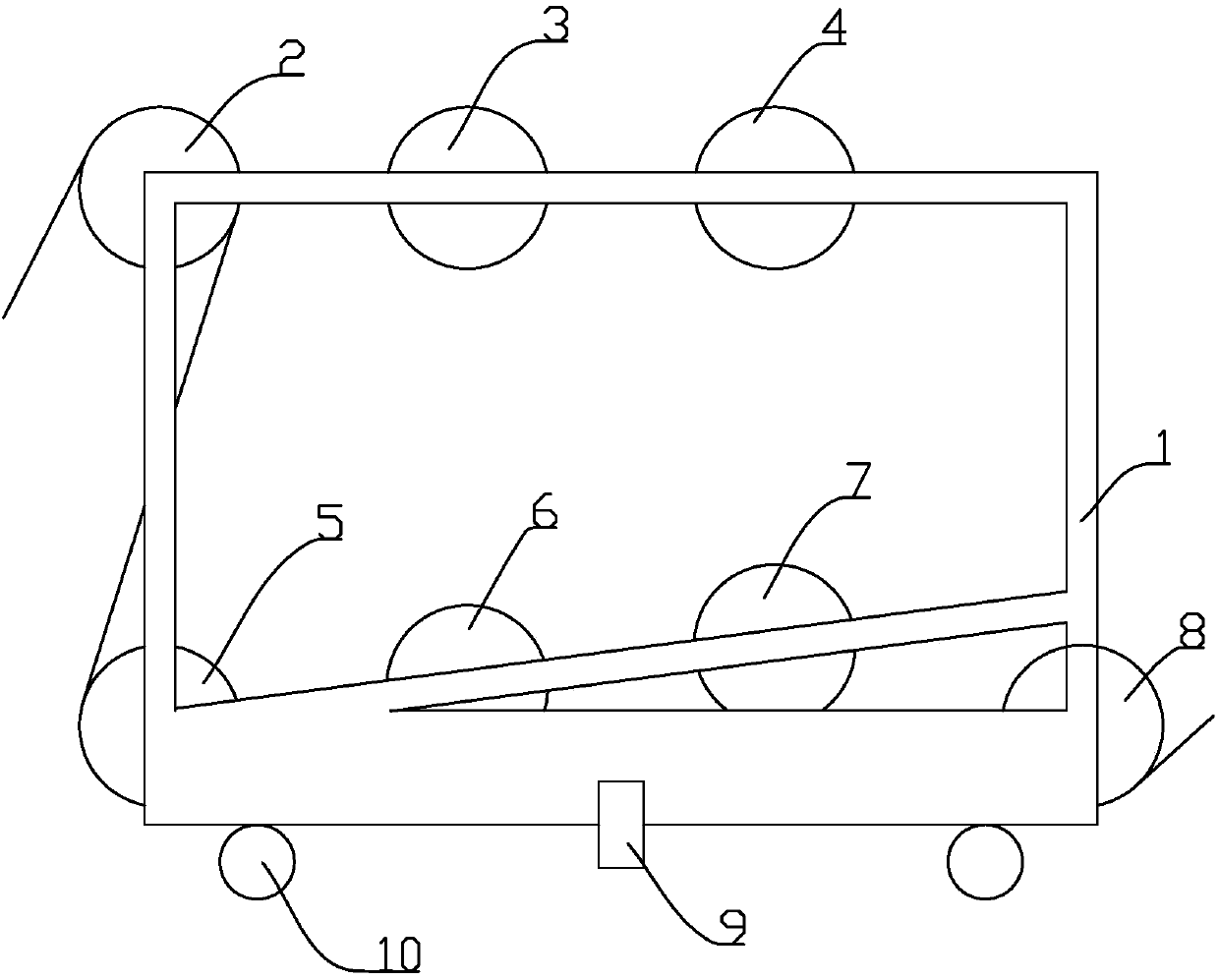

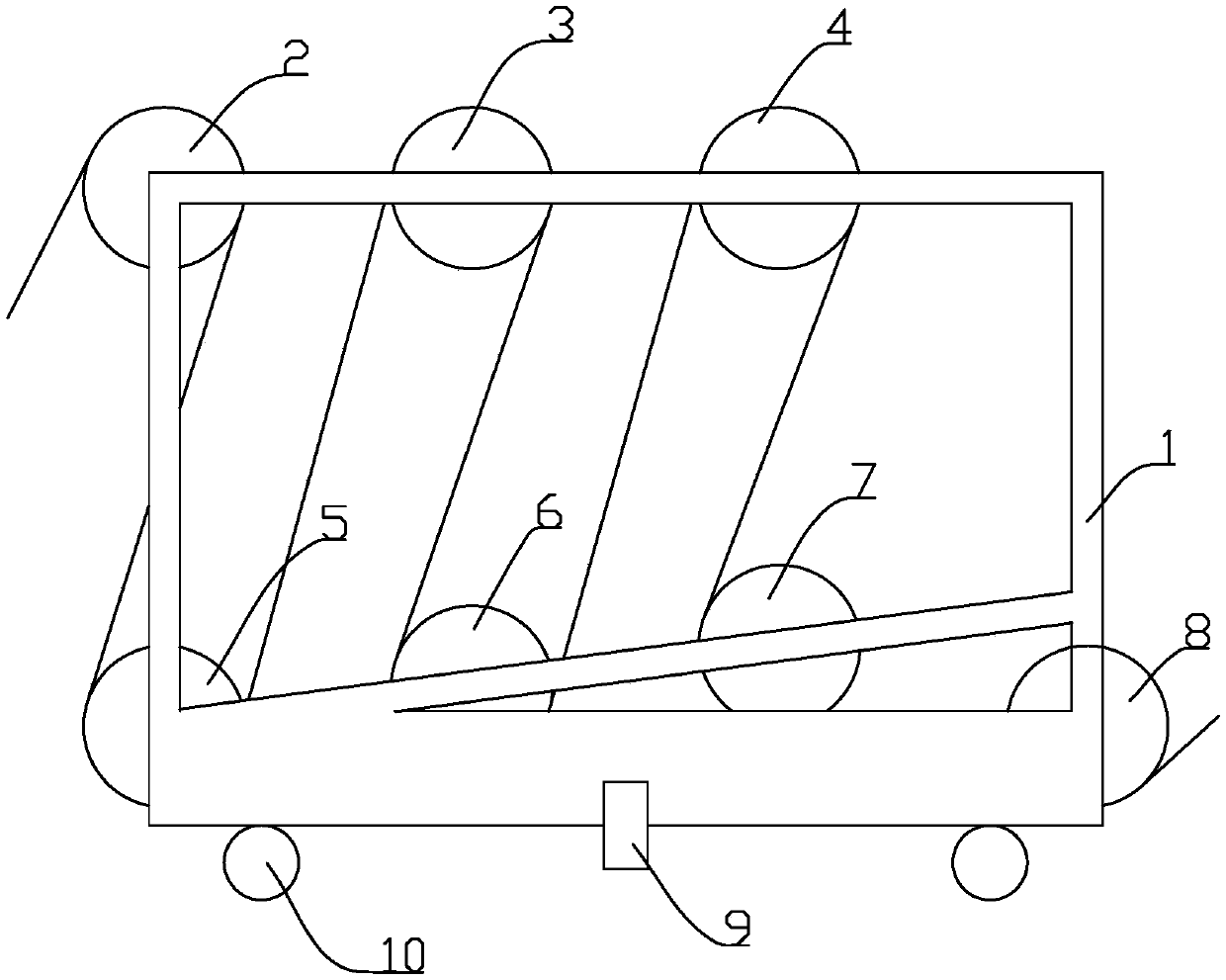

ActiveCN103662887ASimple structureGood synchronizationRegistering devicesArticle feedersPaperboardEngineering

The invention relates to a paper feeding mechanism of a paperboard pasting machine. The paper feeding mechanism comprises a frame. At least two conveying belts driven by a power source are arranged on the frame and are separated from each other. Conveying outlets of the conveying belts face a main unit of the paperboard pasting machine. Retainers capable of moving up and down are arranged in the space between the conveying belts, and up and down movement routes of the retainers pass through conveying planes of the conveying belts. The retainers are connected with transmission control devices for driving the same to move up and down. The transmission control devices are arranged below the conveying planes of the conveying belts. The conveying belts and the transmission control devices cooperate with the main unit of the paperboard pasting machine in working, and paper on the conveying belts is prevented from moving by up and down movements of the retainers. As the up and down movements of the retainers are controlled by the transmission control devices which cooperate with the main unit of the paperboard pasting machine in working, released paper on the conveying belts continue to move into the main unit to reach a working station rightly. The paper feeding mechanism has the advantages of convenience and flexibility and high stability in paper feeding.

Owner:温州旭弘机械有限公司

Paper feeding device

InactiveCN109259644AImprove work coordinationAchieve separationDomestic applicationsVertical barEngineering

A paper feeding device is disclosed, and includes a box body, the box body is fixedly provided with a discharge cavity with an opening facing upward, a left-right symmetrical splint is rotatably arranged on that rear end wall of the discharge cavity, a plurality of paper cylinders arranged in an arrangement are arranged between the splints, a rotating cavity is communicated with the front end surface of the discharge cavity, a link rod arrange in that rotating chamber is rotatably arranged on the front end surface of the splint, the connecting rods are rotatably arranged with each other, a movable rod located in the rotating chamber is rotatably arranged with the connecting rod, the movable rod is fixedly provided with an inner cavity with an opening facing downward, and a vertical bar fixed to the lower end wall of the rotating cavity is slidably arranged with the inner cavity. The device has simple structure and convenient use, and adopts a cam-type moving mechanism to realize the separation of the paper cylinder, thereby improving the utilization rate and the paper feeding efficiency of the device, realizing the high-efficiency control of the paper cylinder through a stable ringstructure, and improving the quality of the paper drawing and the reliability of the device.

Owner:永康仁诒电子科技有限公司

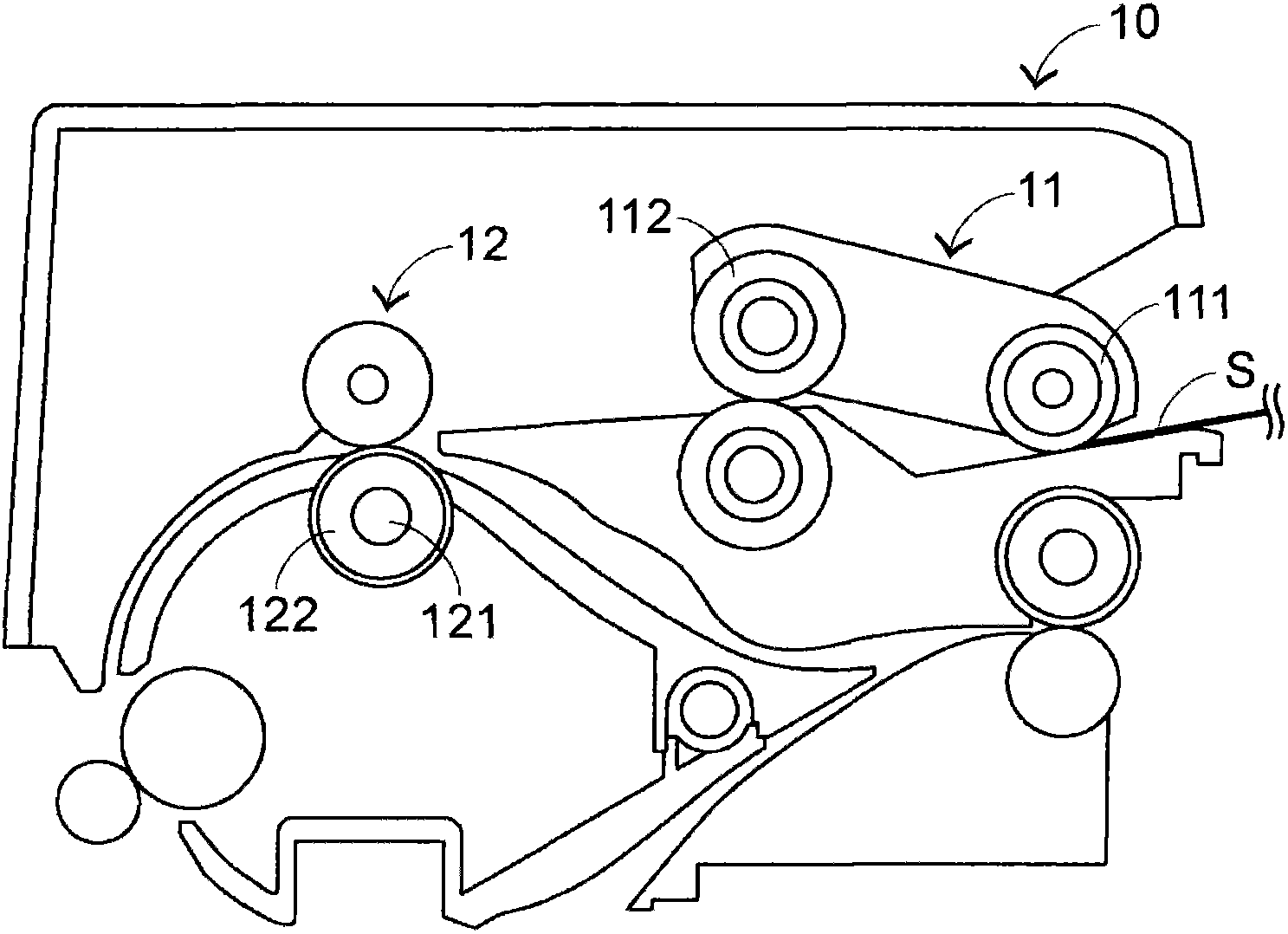

Automatic paper advance device

InactiveCN103121597ASolve the skewShorten the timeArticle feedersArticle separationEngineeringFront edge

The invention provides an automatic paper advance device. The automatic paper advance device comprises a paper obtaining device, a first conveying idler wheel set and a second conveying idler wheel set. The first conveying idler wheel set comprises a first rotary shaft, a first idler wheel and a power connection device. When the power connection device is connected with the first rotary shaft and the first idler wheel to convey a first piece of paper, the first rotary shaft drives the first idler wheel to rotate. When the front edge of the first piece of paper reaches to the second conveying idler wheel set, the paper drives the first idler wheel to rotate at a high speed, and the power connection device is enabled to be released from the power connection with the first idler wheel and the first rotary shaft. And then the first idler wheel enters in a static state to rectify the skew of the next piece of paper. The automatic paper advance device is capable of solving the problem of the skew of the paper, improving paper advance efficiency, and greatly reducing working time.

Owner:PRIMAX ELECTRONICS LTD

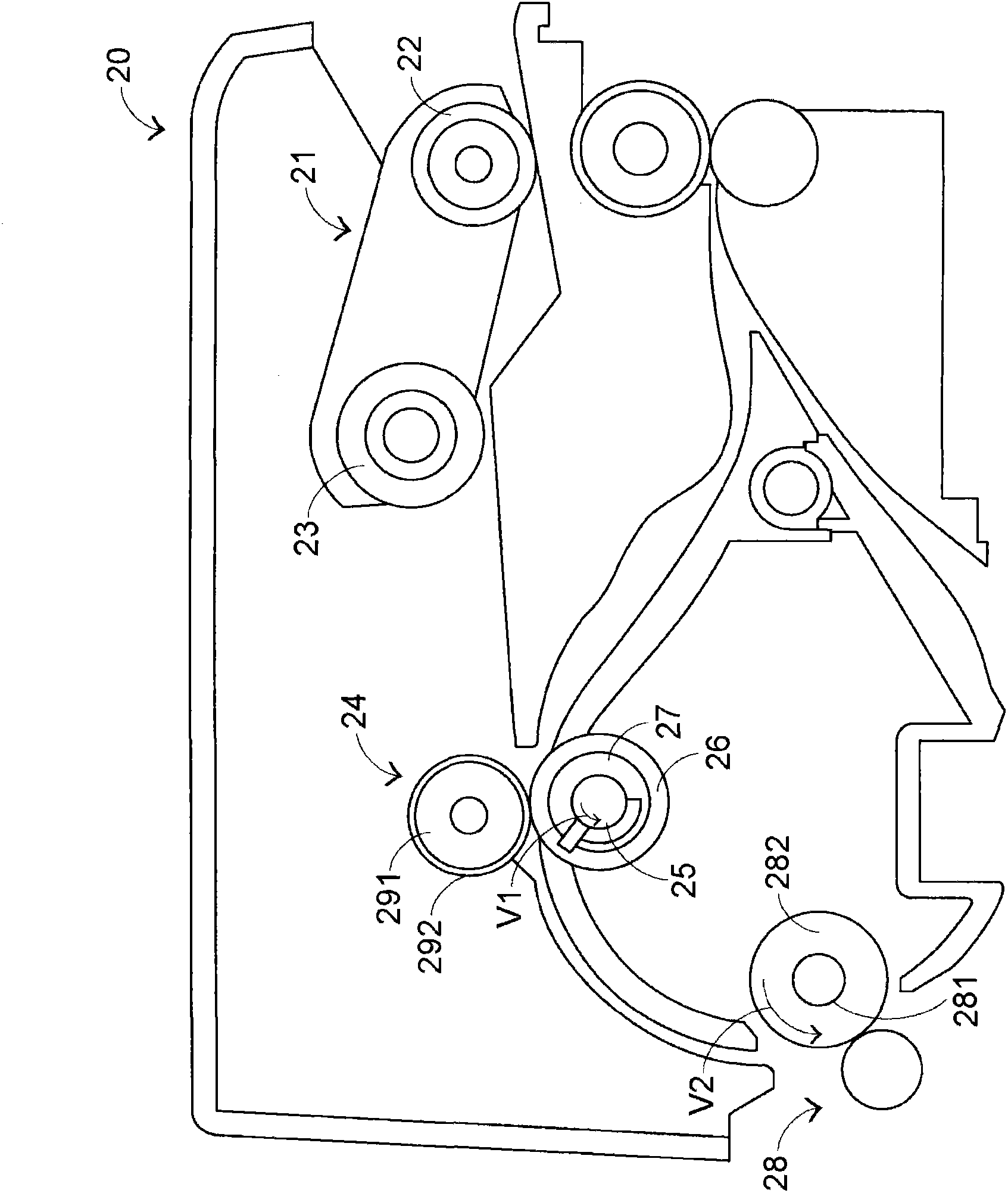

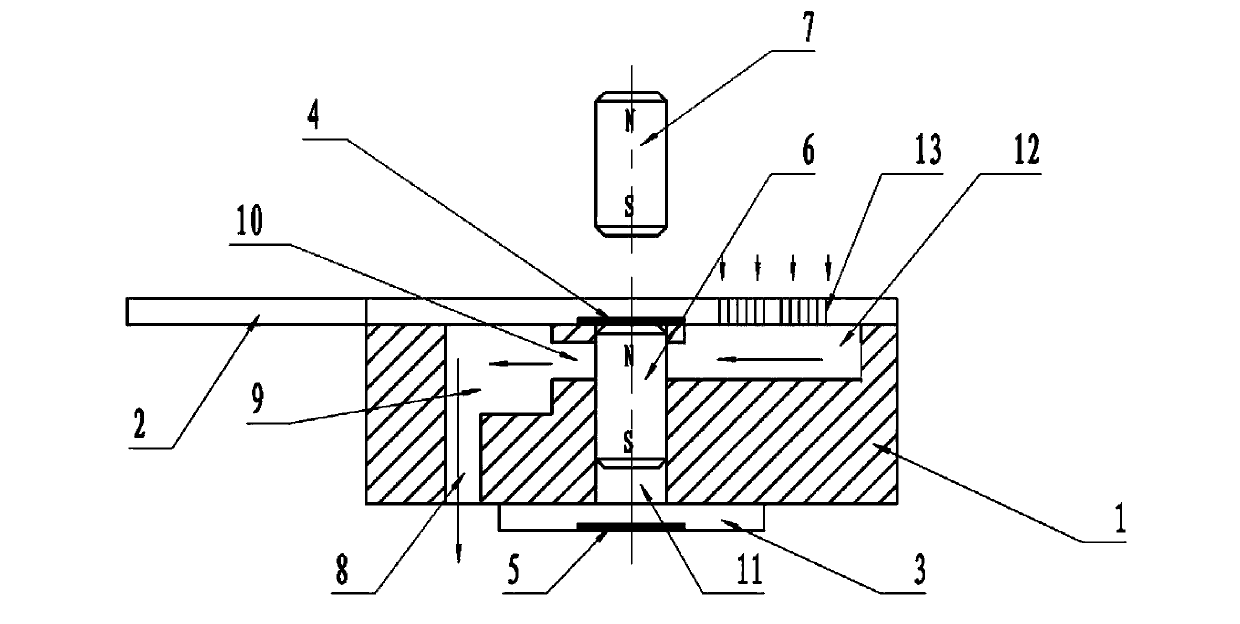

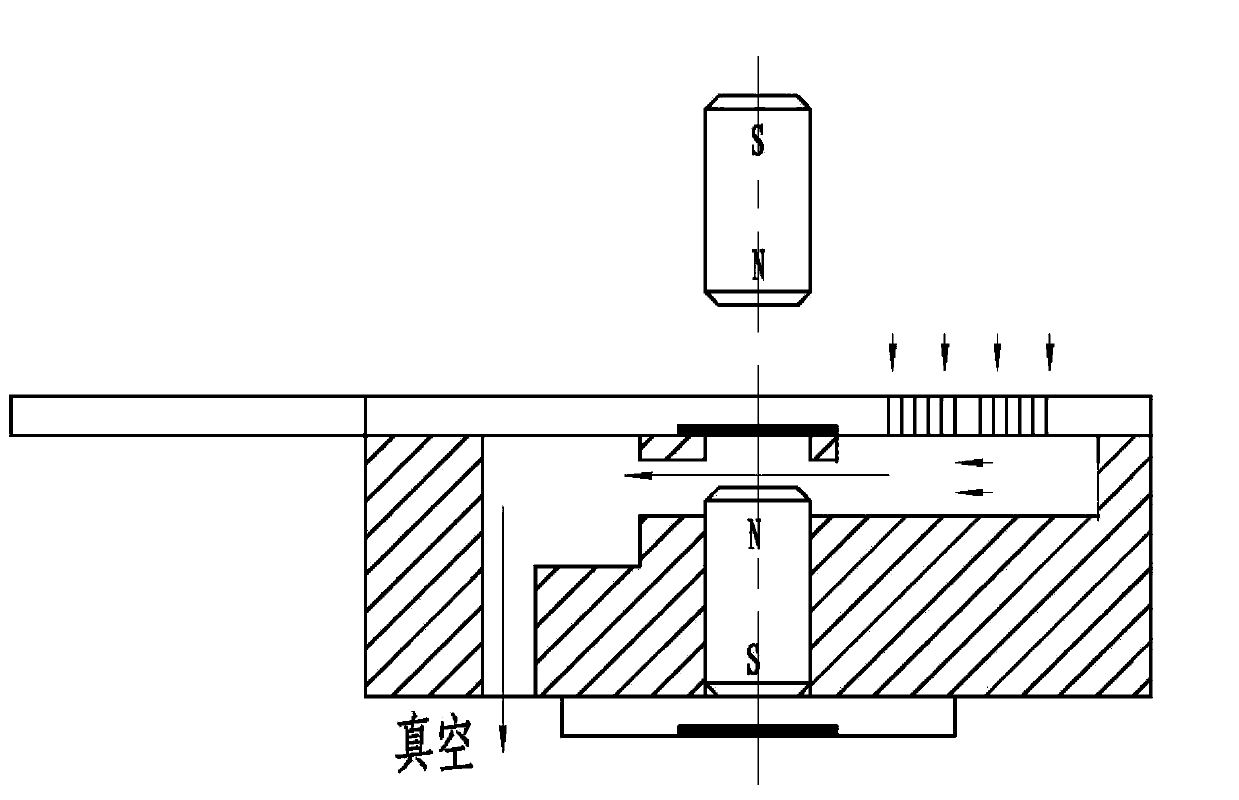

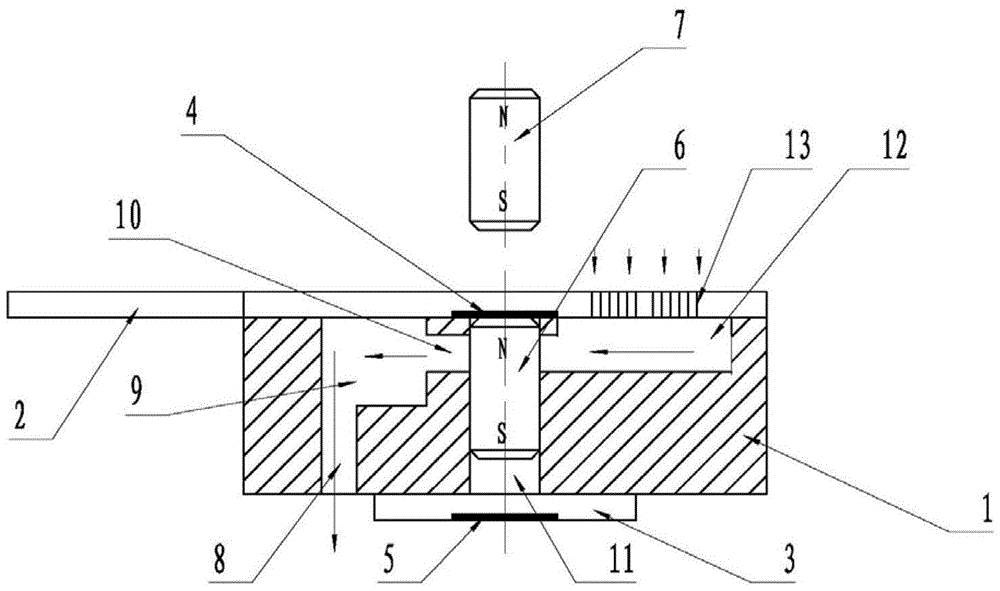

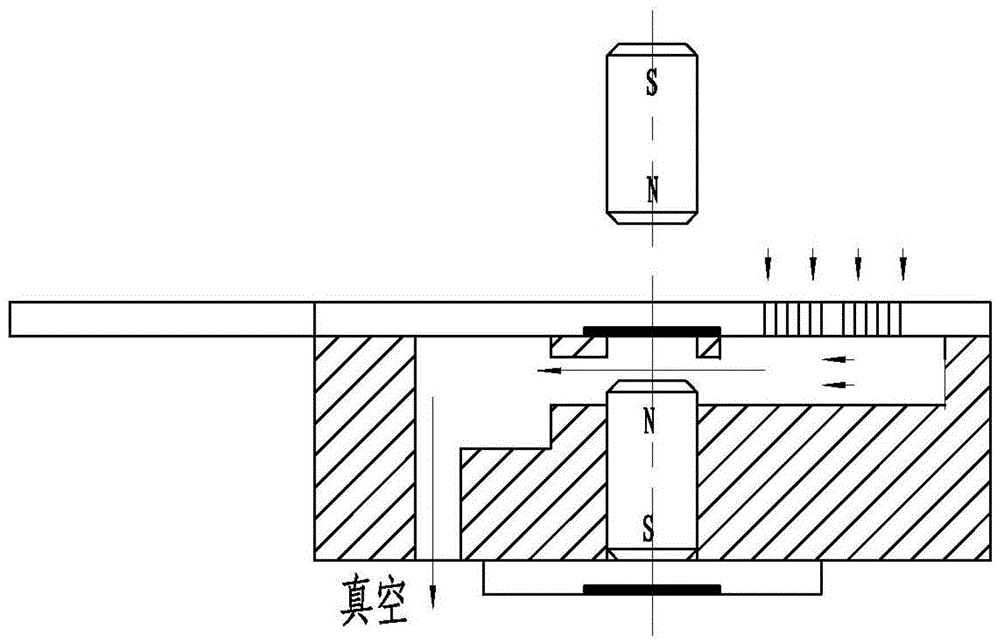

Vacuum paper feeding device for flat pressing and planar gold stamping die cutting machine

ActiveCN103863858AEasy to adjust the number of opening and closingQuick responseArticle feedersPulp and paper industryMagnet

The invention relates to a vacuum paper feeding device for a flat pressing and planar gold stamping die cutting machine. The vacuum paper feeding device for the flat pressing and planar gold stamping die cutting machine comprises a vacuum drain body, a micropore cover plate, a lower cover plate, an upper retaining iron piece, a lower retaining iron piece, a permanent magnet valve core and an open and close permanent magnet; the upper retaining iron piece is fixed on the micropore cover plate; the lower retaining iron piece is fixed on the lower cover plate; a vacuum micropore channel, a branch vacuum channel, a main vacuum channel and a vacuum outlet which are communicated sequentially are arranged in the vacuum drain body; a micropore group which is communicated with the vacuum micropore channel is formed in the micropore cover plate; the open and close permanent magnet is arranged corresponding to the permanent magnet valve core which is arranged in the vacuum drain body. Compared with the prior art, vacuum paper feeding device for the flat pressing and planar gold stamping die cutting machine has the advantages of being quick in response speed, high in paper feeding quality and paper feeding efficiency, enabling the number of open paper sucking micro pores and the number of closed paper sucking micro pores to be conveniently adjusted, being not prone to scratch papers in a paper feeding process and the like.

Owner:SHANGHAI ETERNAL MACHINERY

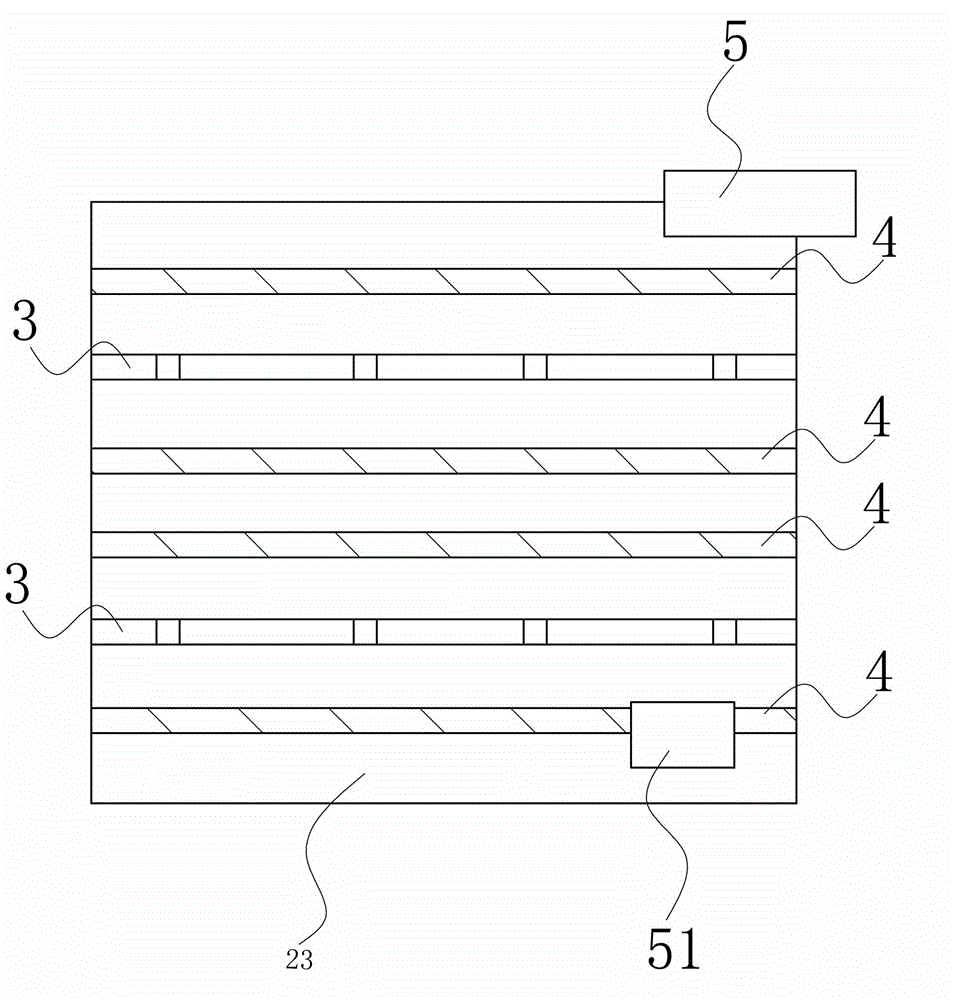

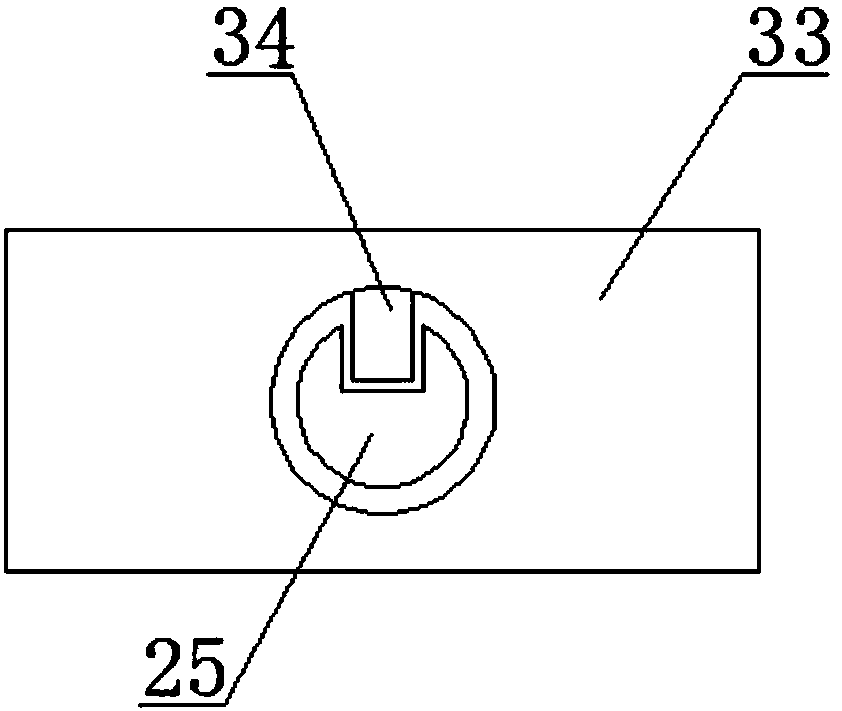

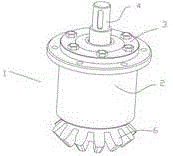

Splicer for corrugated board production line

InactiveCN106882615AImprove paper feeding efficiencyWill not oppressFunction indicatorsArticle feedersCardboardProduction line

The invention discloses a splicer for a corrugated board production line. The splicer comprises a fixed shaft barrel; the fixed shaft barrel is provided with a driving shaft body therein; the driving shaft body comprises a shaft rod; the shaft rod is provided with a pair of support bearings; the bottom of the shaft rod is provided with a detachable feeding disk head. When corrugated boards on a splicer rack is conveyed to the opening of the splicer rack, multiple feeding disk heads rotate synchronously so that the corrugated boards are quickly fed to a conveyer belt under the splicer rack, which is quick and reliable and is not liable to slip; therefore the feeding efficiency of corrugated boards is greatly increased. Besides, since the double bearing support is adopted, the feeding disk heads rotate stably and boards will not be compressed so that the splicer is especially suitable for use in high-speed corrugated board production lines.

Owner:SHANGHAI YUNSHU INTPROP CONSULTANCY CO LTD

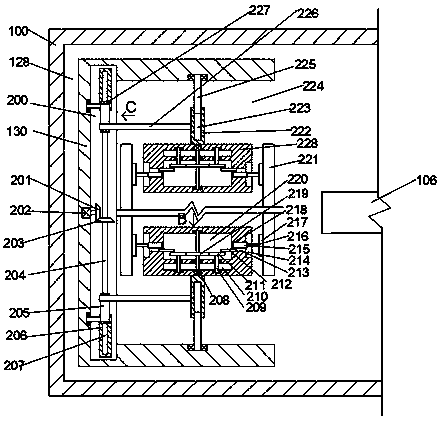

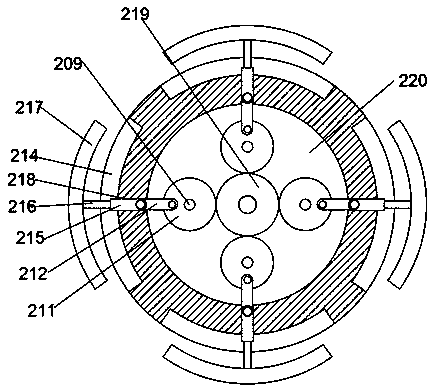

Rotating paper conveying device

InactiveCN108313783ALoad balancingOvercome the problem limited by transmission distanceArticle feedersInlet channelPulp and paper industry

The embodiment of the invention discloses a rotating paper conveying device. The device comprises a rotating beam, a fixing plate and a paper conveying channel, wherein the rotating beam is of a hollow columnar structure, and four long-strip-shaped groove holes which are formed in the outer side wall are formed in the side wall of the rotating beam in the axial direction; the paper conveying channel comprises a paper inlet channel and a paper outlet channel, the fixing plate is arranged at the two ends of the rotating beam, and the paper inlet channel is arranged perpendicular to the paper outlet channel; the paper outlet of the paper inlet channel and the paper inlet of the paper discharging channel of the same paper conveying channel correspondingly communicates with two opposite grooveholes in the side wall of the rotating beam; and the side edge of the paper conveying channel is connected with the fixing plate. Paper conveying is switched between the paper conveying channels, thepaper conveying efficiency is improved; meanwhile, a star conveying mechanism with a synchronous belt is adopted, and the problem that a traditional star conveying mechanism is limited by a conveyingdistance is solved; and meanwhile, the load of the driving medium belt wheel is balanced, so that transmission loss is reduced.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION +1

Paper supply device capable of automatically replacing roll paper

The invention discloses a paper supply device capable of automatically replacing roll paper. The paper supply device comprises a device body, wherein the device body consists of a paper supply box, arotating cylinder and a fixing block, wherein the paper supply box is arranged on the side surface of the device body; the rotating cylinder is arranged on the side surface of the paper supply box; the fixing block is arranged on the side surface of the rotating cylinder. According to the paper supply device capable of automatically replacing roll paper, a speed adjuster is controlled by rotatingan adjusting knob, the rotation speed of a Y2-90L-4 electromotor is further controlled by the speed adjuster, then the rotation speed of a roller is controlled, the paper supply speed is further adjusted, an optimal paper supply effect is adjusted conveniently, and very good practicability is achieved; meanwhile, rolls of which paper is used up are sucked through electromagnets, new rolls are pushed to the middle of the rotating cylinder through hydraulic rods, then paper can be supplied again, the paper supply efficiency is greatly improved, a great amount of labor resources are saved, and the workload of operators is alleviated; in addition, paper is pressed by a paper guide, then the paper can be moved in a correct direction, the paper is prevented from damage, and the paper utilizationrate is increased.

Owner:WEIFANG HUAGUANG DIGITAL EQUIP

Shredder paper feeder with protective cover

InactiveCN102989565AImprove work efficiencySimple structureGrain treatmentsEngineeringMechanical engineering

Owner:NINGBO HAIBO OFFICE MACHINERY

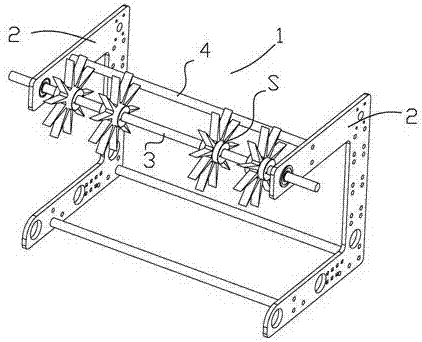

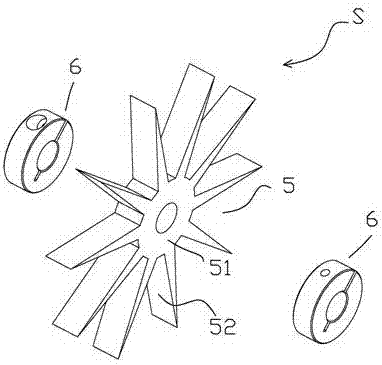

Multipurpose coated paper feeding device

The invention discloses a multipurpose coated paper feeding device. The multipurpose coated paper feeding device comprises a pair of fixed supports which are arranged in parallel, wherein a drive shaft rod and a guide shaft rod are arranged at the top of each fixed support; a paper feeding assembly array composed of paper feeding assemblies is arranged on each drive shaft rod; each paper feeding assembly comprises a paper feeding shifting disc and a pair of annular limit clamping rings, and the limit clamping rings are located at the two sides of the paper feeding shifting disc; each paper feeding shifting disc comprises an annular shifting disc seat; a shifting sheet array composed of flexible shifting sheets is arranged on the sidewall of each shifting disc seat; and a transversally-formed locking screw hole and a longitudinally-formed adjustment slit are formed in each limit clamping ring. A user directly connects each drive shaft rod with an external drive motor. After the drive motor starts, the paper feeding shifting discs prepared from rubber rapidly rotate, the shifting sheets directly and rapidly shift out coated paper in paper grooves, the operation is fast and rapid, and slip is not easily caused, so that the coated paper feeding efficiency is greatly increased.

Owner:王琳

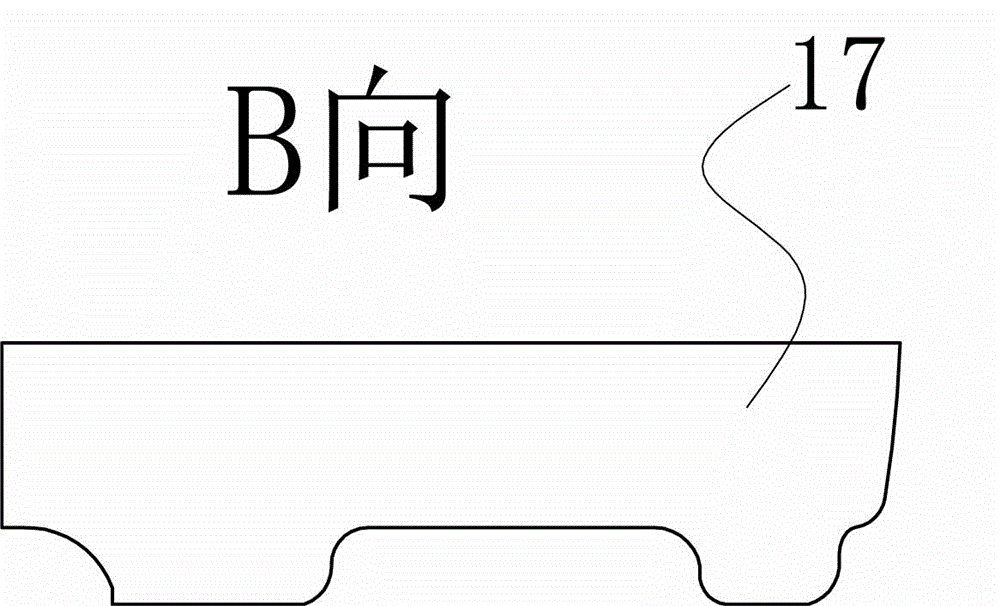

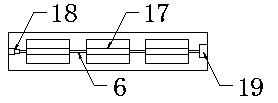

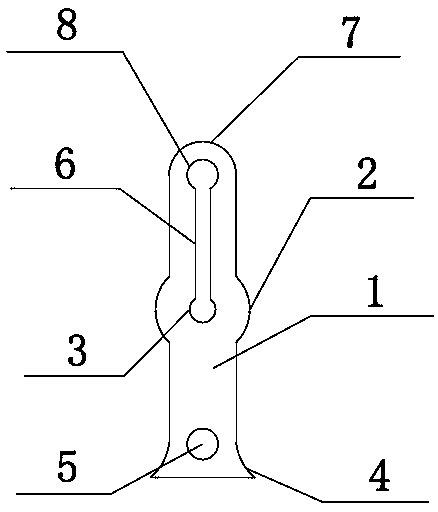

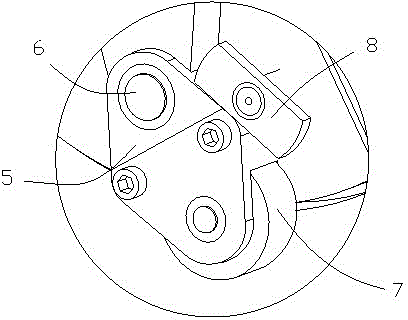

Paper-lifting connecting plate of printing press

InactiveCN103350912AImprove paper feeding efficiencyImprove performanceArticle feedersEngineeringPrinting press

The invention relates to a paper-lifting connecting plate of a printing press. The paper-lifting connecting plate of the printing press comprises a plate body (1). Circular arc parts (2) are symmetrically arranged on the two sides of the middle portion of the plate body (1). Central holes are formed in the centers of the circular arc parts (2). One end of the plate body (1) is a circular arc end (7). The other end of the plate body (1) is a peculiar-shaped end (4), wherein circular arcs are arranged on the two sides of the peculiar-shaped end (4). An end hole (8) is formed in the center of the circular arc end (7). A connecting hole (5) is formed in the peculiar-shaped end (4). The paper-lifting connecting plate of the printing press is simple in structure, reasonable in design, and stable and solid in connection, improves the paper feed efficiency of the printing press, and improves the overall performance of the printing press.

Owner:KUNSHAN DACHANG MACHINERY MFR

Paper feeding mechanism of a cardboard laminating machine

ActiveCN103662887BSimple structureGood synchronizationRegistering devicesArticle feedersPaperboardEngineering

The invention relates to a paper feeding mechanism of a paperboard pasting machine. The paper feeding mechanism comprises a frame. At least two conveying belts driven by a power source are arranged on the frame and are separated from each other. Conveying outlets of the conveying belts face a main unit of the paperboard pasting machine. Retainers capable of moving up and down are arranged in the space between the conveying belts, and up and down movement routes of the retainers pass through conveying planes of the conveying belts. The retainers are connected with transmission control devices for driving the same to move up and down. The transmission control devices are arranged below the conveying planes of the conveying belts. The conveying belts and the transmission control devices cooperate with the main unit of the paperboard pasting machine in working, and paper on the conveying belts is prevented from moving by up and down movements of the retainers. As the up and down movements of the retainers are controlled by the transmission control devices which cooperate with the main unit of the paperboard pasting machine in working, released paper on the conveying belts continue to move into the main unit to reach a working station rightly. The paper feeding mechanism has the advantages of convenience and flexibility and high stability in paper feeding.

Owner:温州旭弘机械有限公司

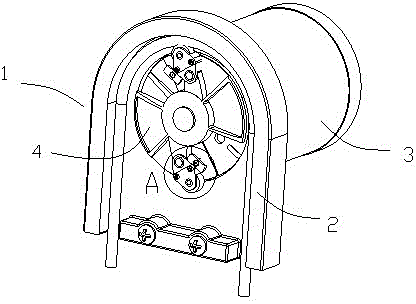

Paper feeder of die-cutting machine

InactiveCN103552862AImprove paper feeding efficiencyLow costArticle feedersCircular discElectric machinery

The invention discloses a paper feeder of a die-cutting machine. The paper feeder of the die-cutting machine comprises a driving motor and a guide groove casing, wherein a rotatable guide disc is arranged at the head part of the driving motor; a rotatable guide bracket is arranged at the bottom of the guide disc; a fixed pivot is arranged at the tail part of the guide bracket; a guide rubber wheel is arranged at the head part of the guide bracket; and a rotatable press bar is arranged on the guide disc further. According to the paper feeder of the die-cutting machine, a user can change the paper feeding angle according to the paper thickness by the aid of the rotatable guide bracket and the rotatable press bar on the guide disc, the operation is simple, the paper feeding efficiency of the die-cutting machine is greatly improved, the cost is low, and the practicability is high.

Owner:赵士立

A kind of enterprise paper voucher entry management equipment and using method thereof

ActiveCN113420765BEasy to organizeEasy to useTelevision system detailsColor television detailsBusiness enterpriseVoucher

The invention relates to the technical field of paper voucher entry, in particular to an enterprise paper voucher entry management device and a method for using the same. The input rack, the arrangement module includes a placement box, the bottom surface of the placement box is fixedly connected with two support brackets that are fixedly connected to the top surface of the bottom plate, and the tops of the two outer sides of the placement box are located on one side of the conveying module. Both are fixedly connected There are drive modules. In the present invention, the elliptical block in contact with the top surface of the sliding block is fixedly connected to one end of the rotating rod, and the power mechanism can drive the elliptical block to rotate. When the block is rotated, the paper voucher on the placing board can be shaken up and down, so that the paper voucher is aligned with one side of the placing board, no manual sorting is required, and the sorting is relatively simple and easy to use.

Owner:宜春职业技术学院

Leading edge feeder for corrugated cardboard printing equipment

ActiveCN108819470BOvercoming the problem of not being able to start and stop quicklyPaper feeding speedPrinting press partsArticle separationCardboardControl engineering

The invention discloses a leading edge paper feeding part for corrugated paper printing equipment and its driving device. The driving device includes a servo motor, a shaft coupling and a main control device. Motor, each servo motor is connected to a paper feeding shaft through a coupling, and each servo motor is connected to the main control device; the main control device is equipped with a time signal synchronization monitoring module, an information input module, a main control module, and a drive circuit and encoder. The front edge paper feeding part is equipped with the above-mentioned driving device, including the paper feeding platform and the lifting mechanism of the lifting plate. The lifting plate on the paper feeding platform is driven by the lifting plate lifting mechanism to move up and down, and then the servo motor is used to drive each paper feeding shaft to complete the paper feeding. ; Or include a paper feeding platform and a paper supporting mechanism, through the lifting movement of the paper supporting mechanism, and then use the servo motor to drive each paper feeding shaft to complete the paper feeding. The invention can greatly increase the paper feeding speed, and effectively overcomes the problem that the traditional paper feeding device cannot start and stop quickly.

Owner:GUANGZHOU KESHENGLONG CARTON PACKING MACHINE

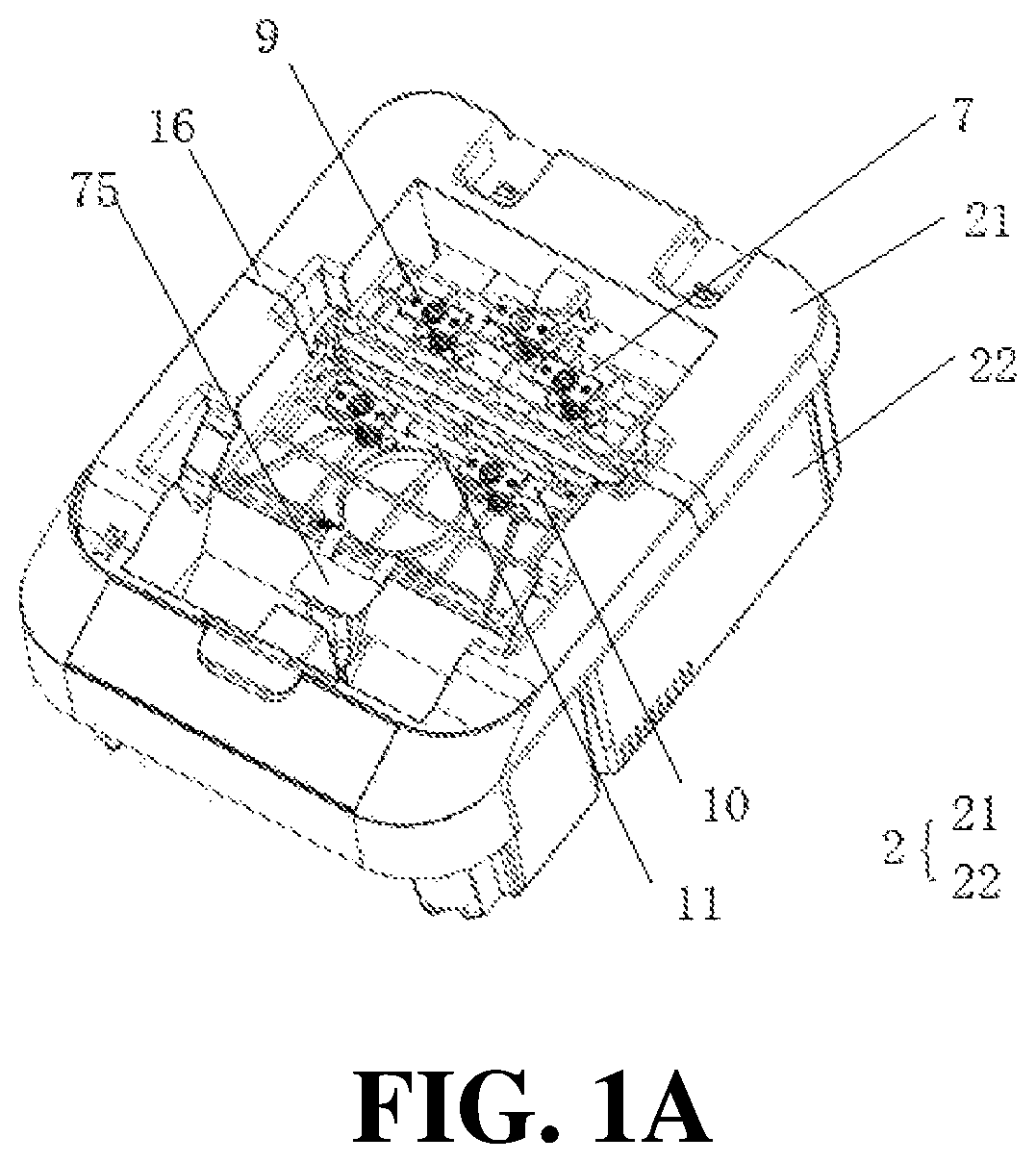

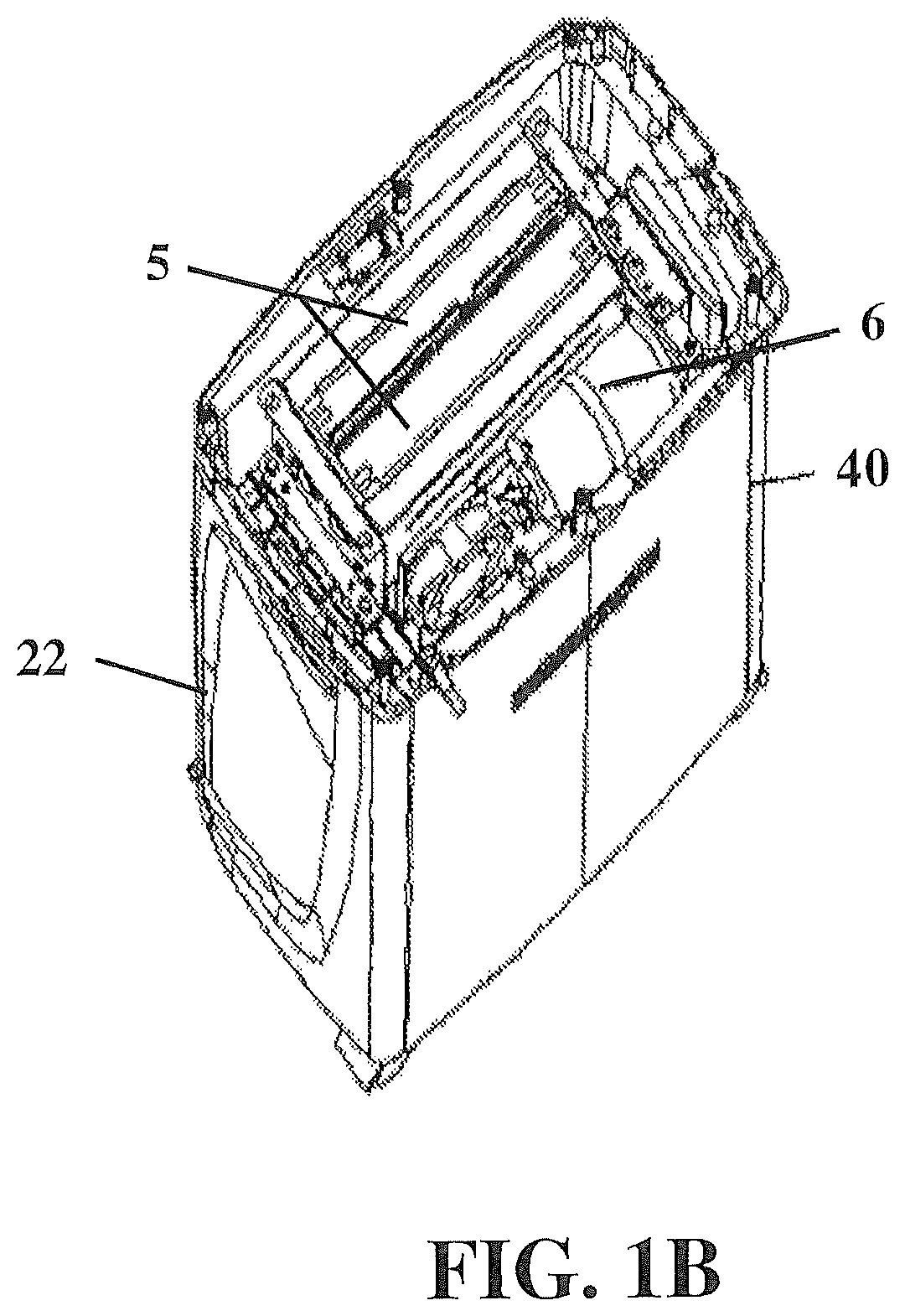

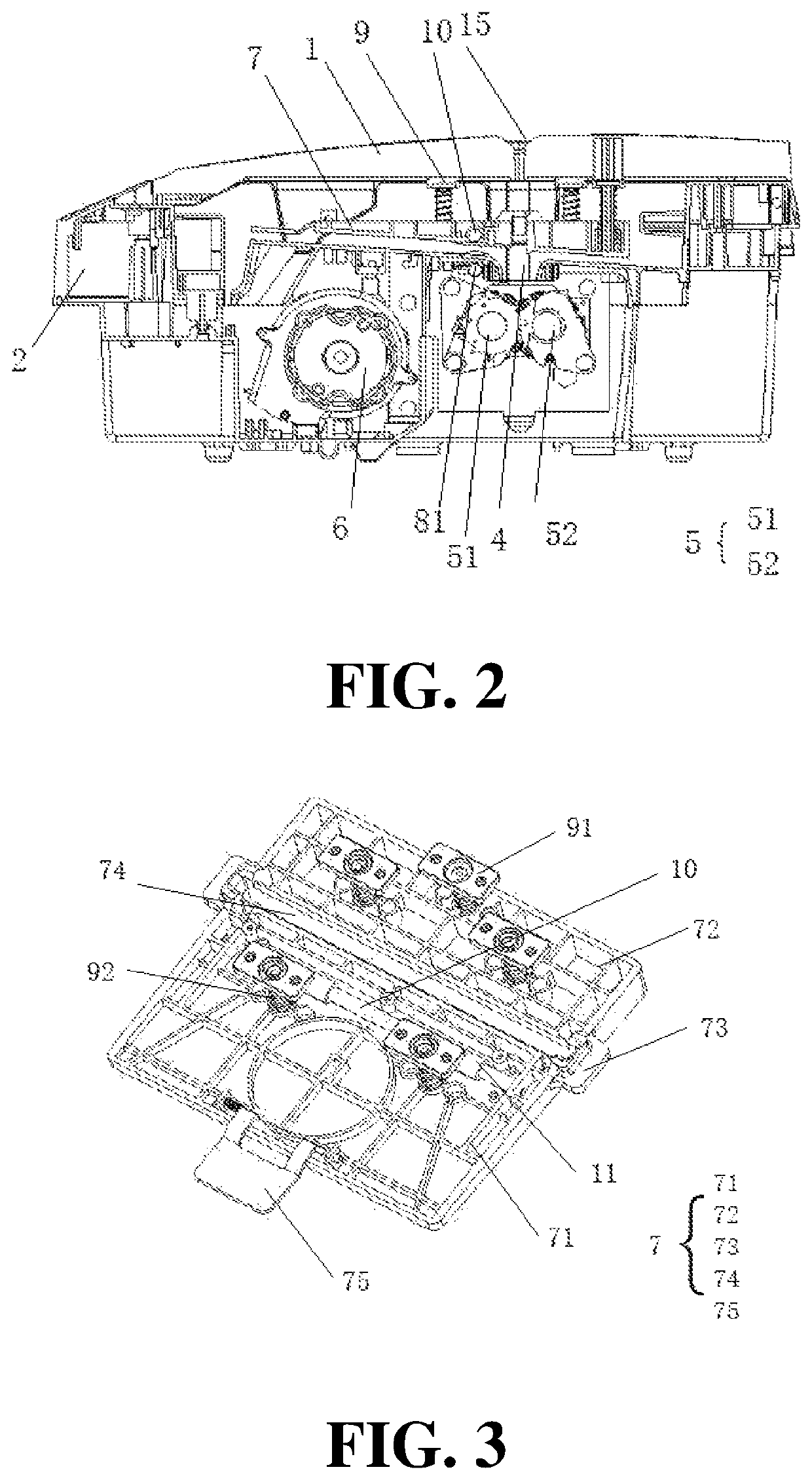

Paper feeder for inspection machine and paper feeding method thereof

ActiveCN103787100BReduce or eliminate scratchesWon't breakArticle feedersArticle separationCardboardPaper sheet

The invention discloses a paper feed machine for a product check machine and a paper feed method of the paper feed machine. The paper feed machine comprises an uninterruptible paper feed mechanism. An induced draft paper supply mechanism is correspondingly arranged above the upper paper outlet end of the uninterruptible paper feed mechanism. A paper aligning plate is vertically arranged on one side of the uninterruptible paper feed mechanism and corresponding to the output end of the induced draft paper supply mechanism. The output end of the induced draft paper supply mechanism and the input end of a blowing paper distributing mechanism are correspondingly arranged. The paper feed method includes the steps that a main paper feed table and an auxiliary paper feed table alternatively support and lift a printed matter stack with printing surfaces placed upwards; printed matter is uninterruptedly supplied to the induced draft paper supply mechanism; the induced draft paper supply mechanism continuously adsorbs a single sheet of printed matter from the position above the printed matter stack and transfers the single sheet of printed matter to the blowing paper distributing mechanism, and then the blowing paper distributing mechanism sends out the single sheet of printed matter after separating the single sheet of printed matter from the induced draft paper supply mechanism. By the adoption of the mode of adsorbing paper feed with the printing surfaces placed upwards, the single sheet of printed matter is uninterruptedly conveyed to a surface quality detector for surface quality detection, and therefore scratches of the printing surfaces of the printed matter are reduced or eliminated.

Owner:HEBEI TIANYUHENG TECH CO LTD +1

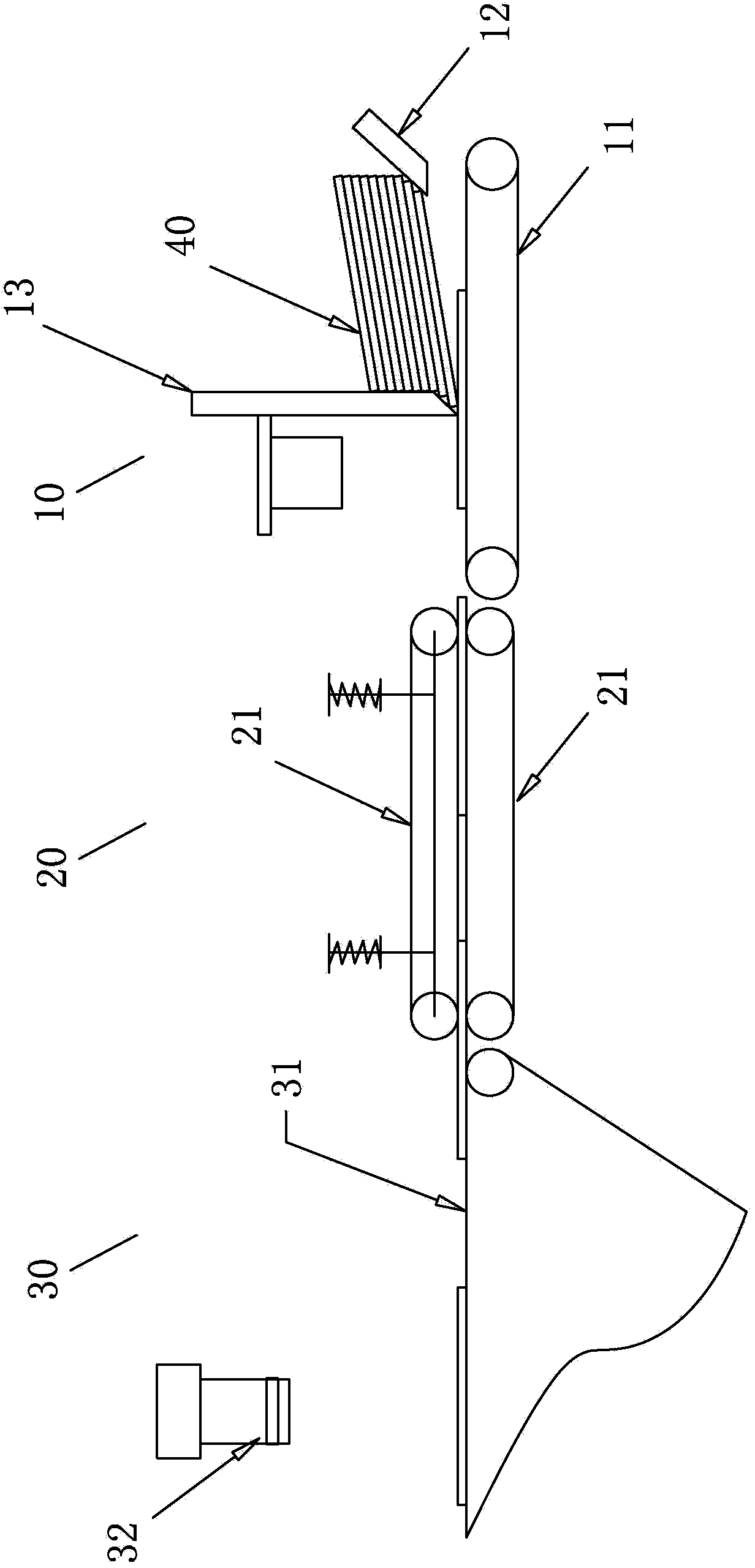

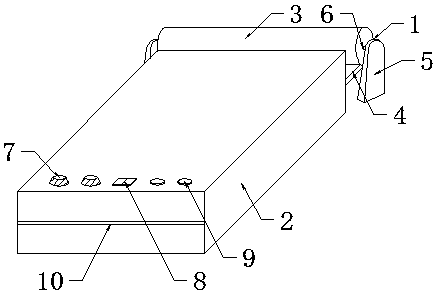

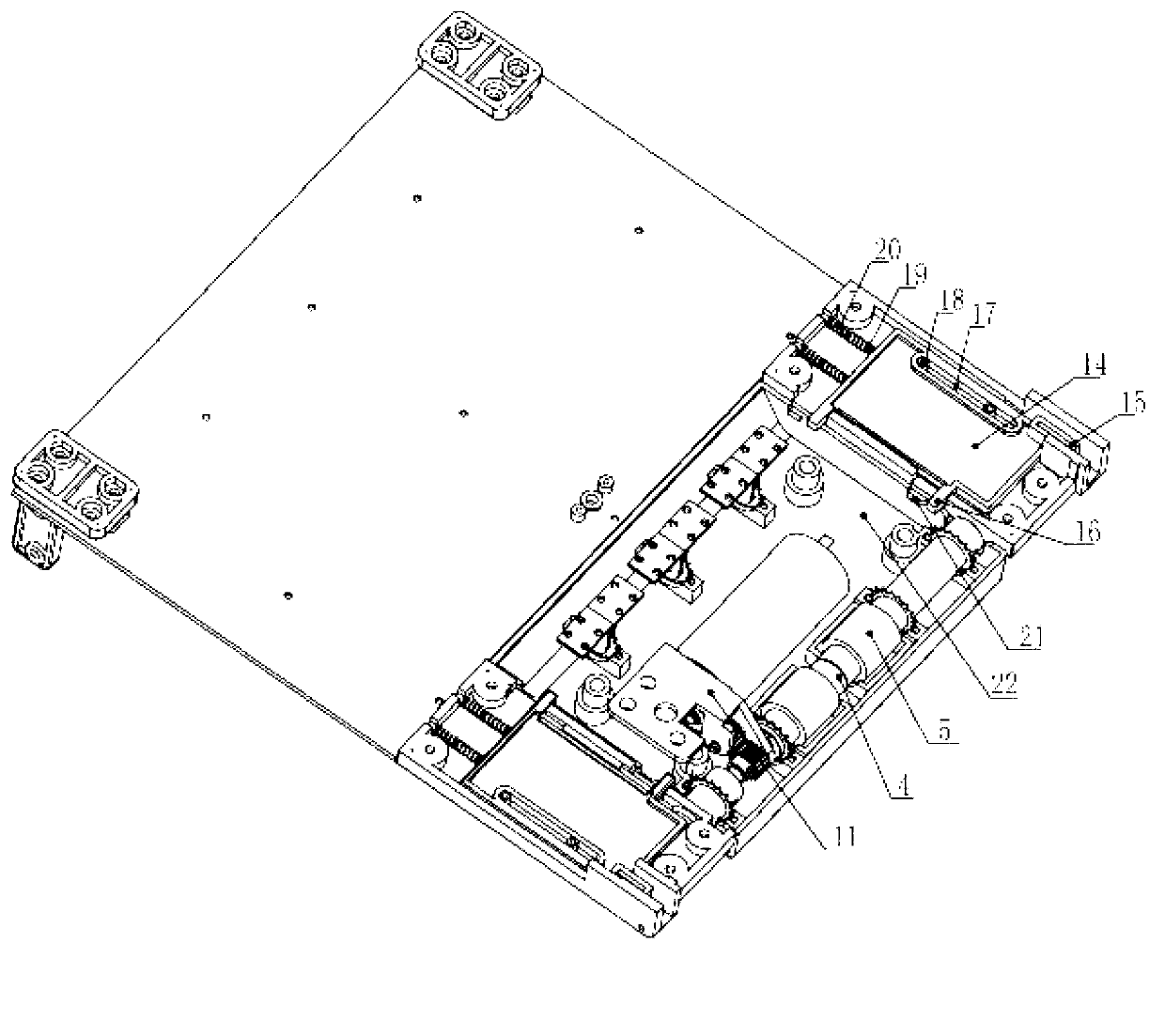

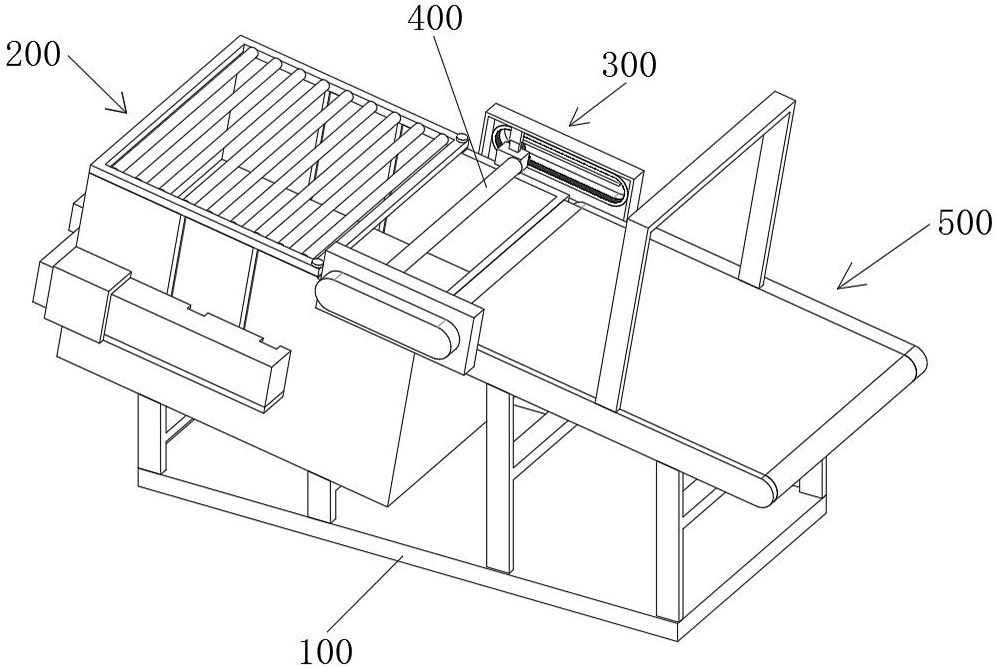

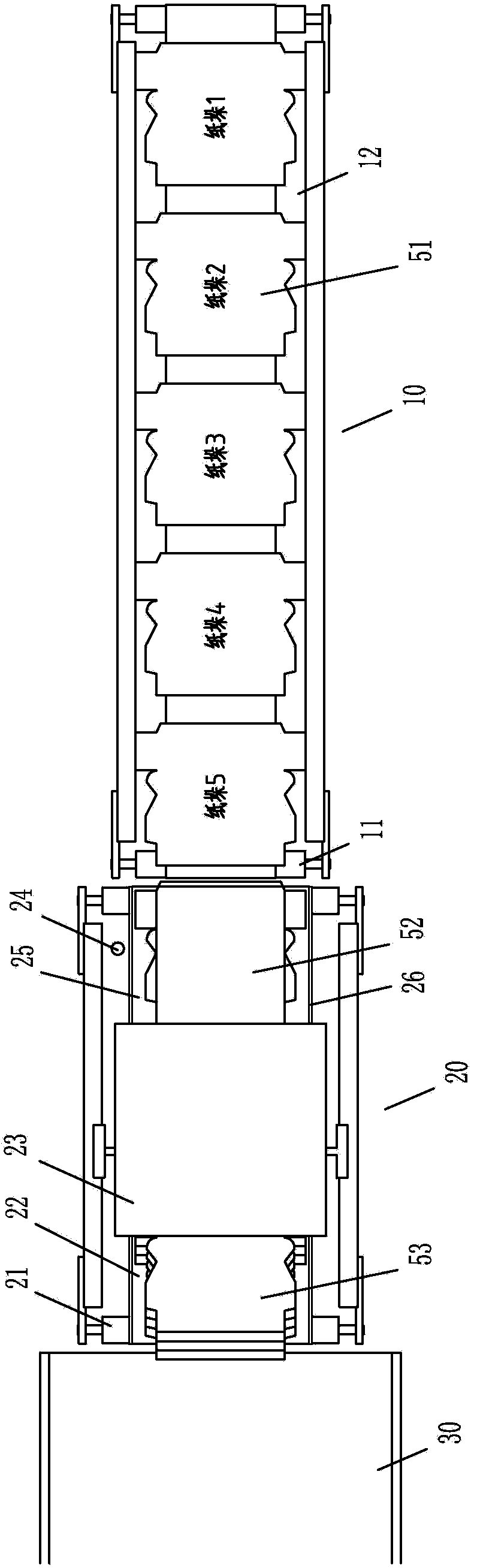

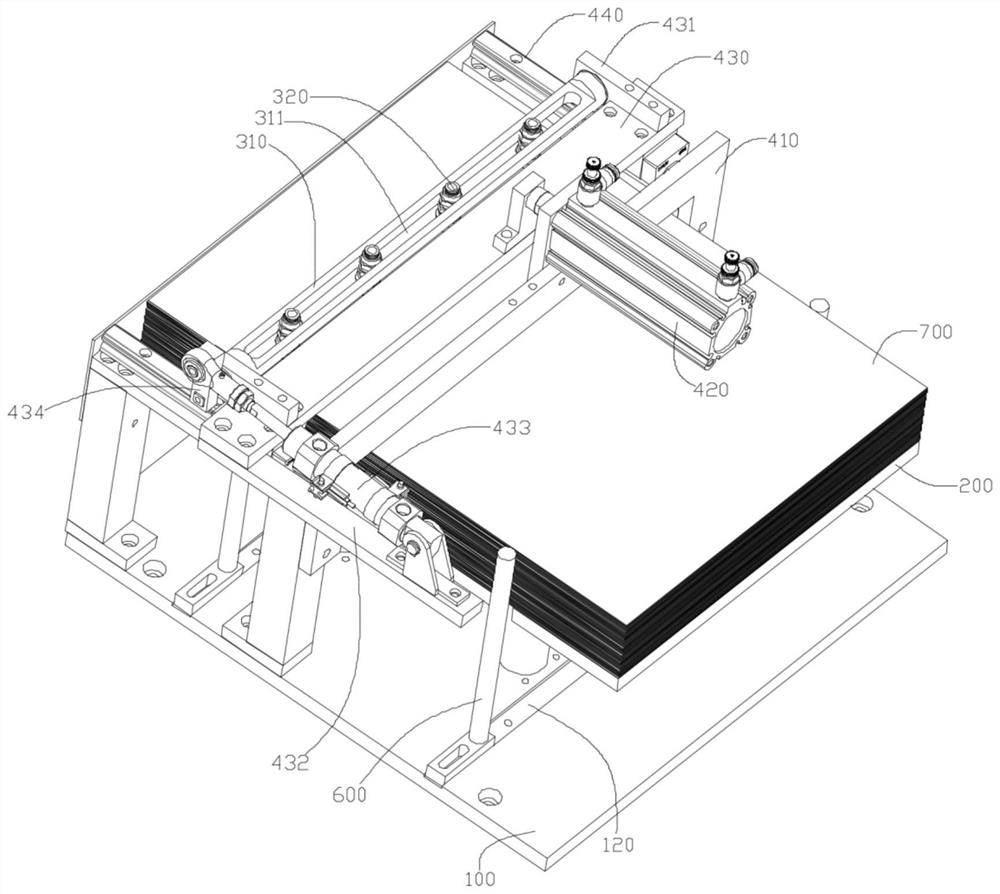

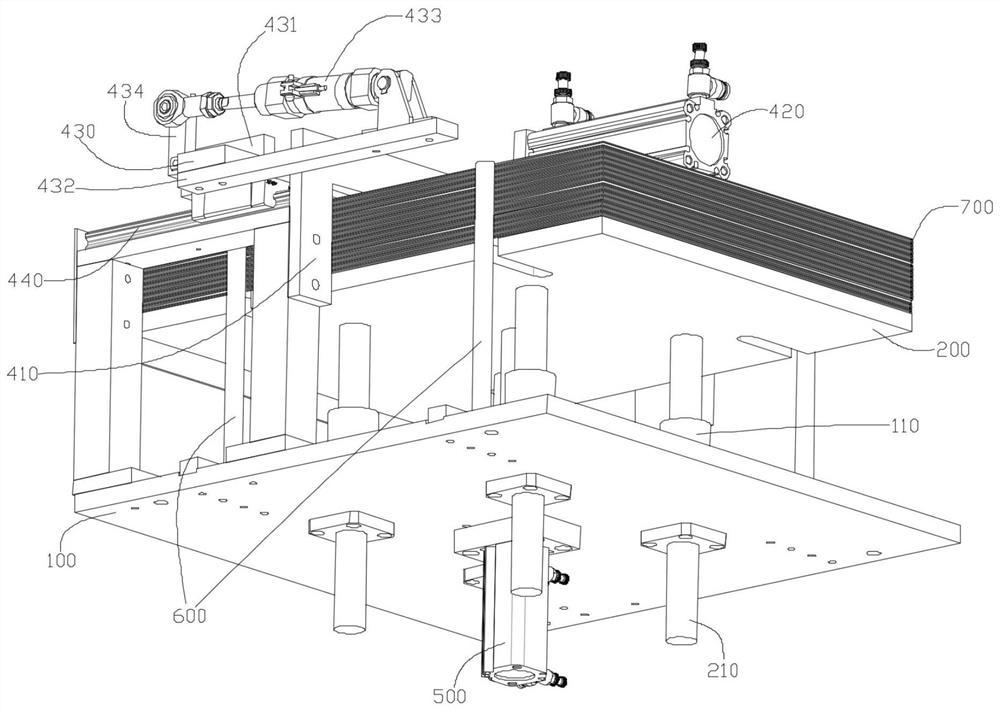

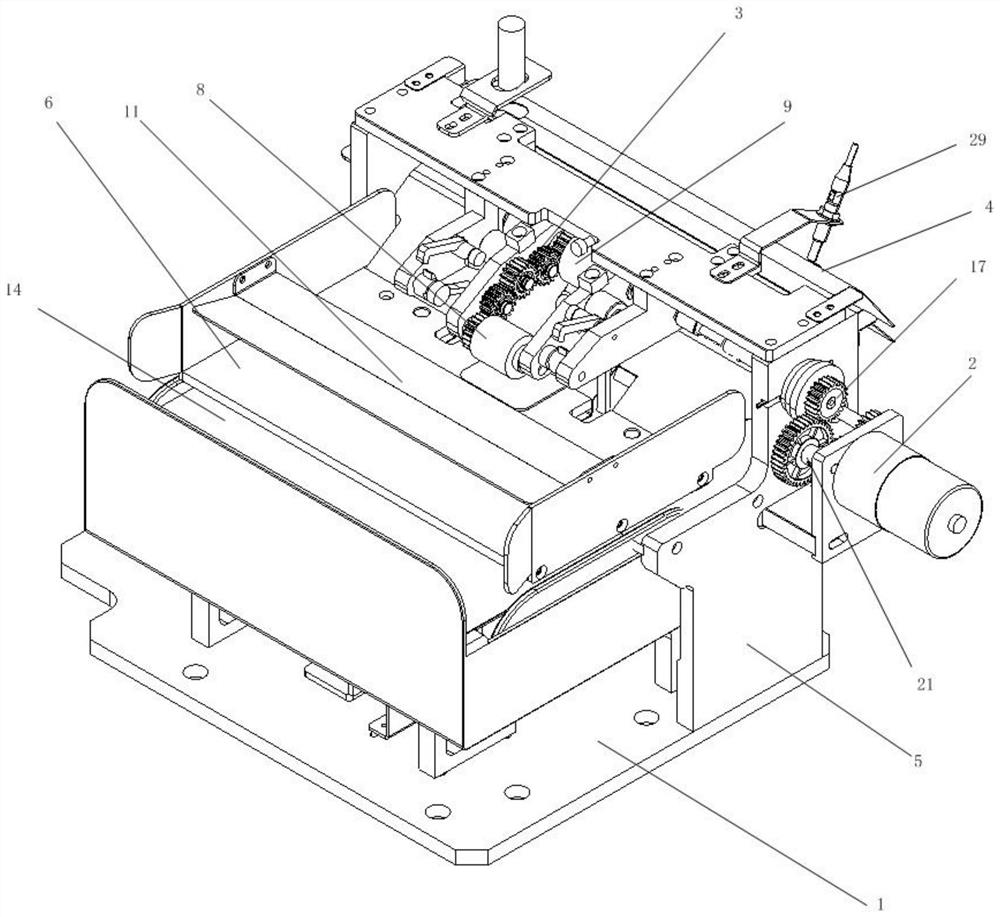

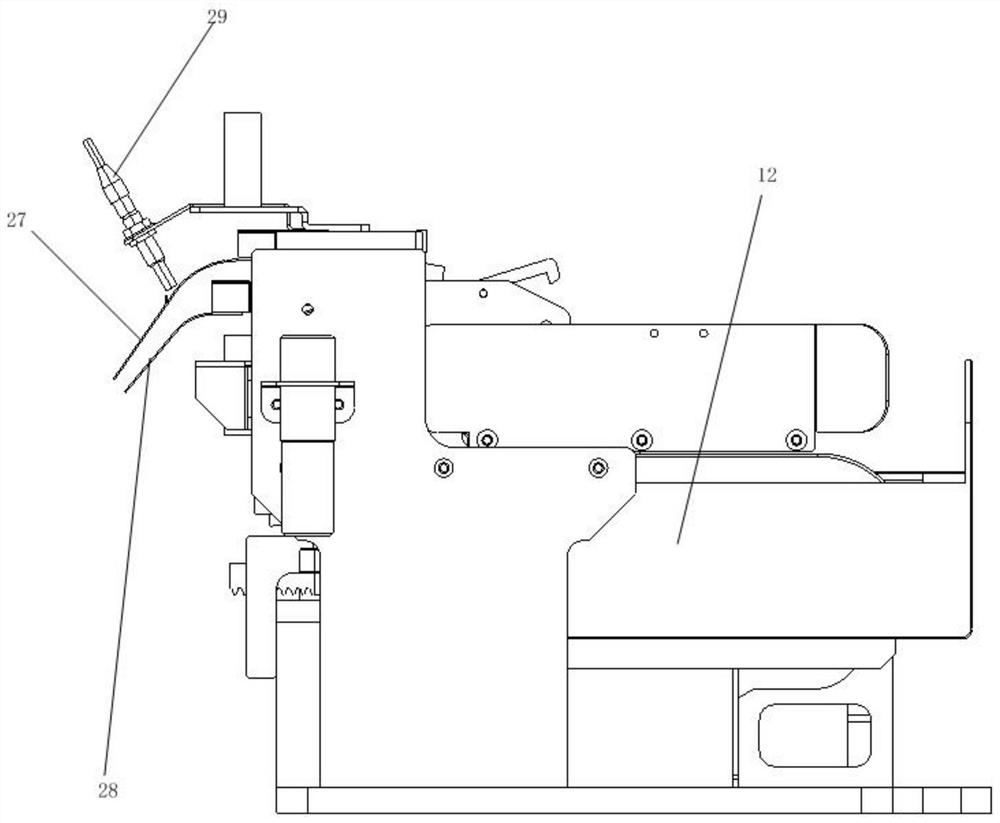

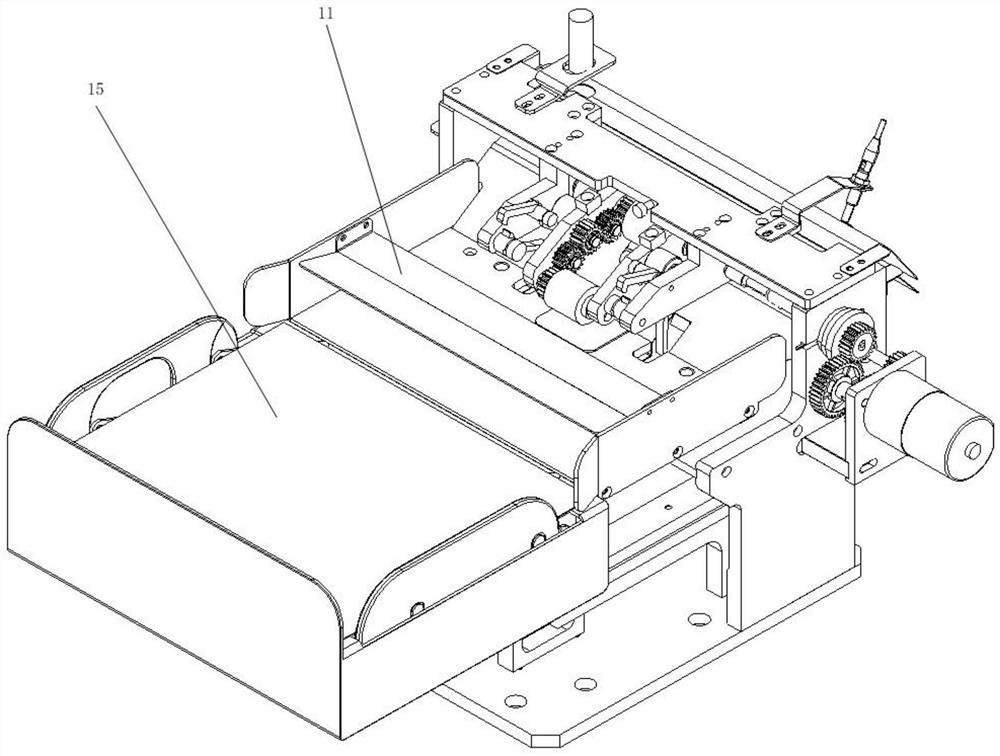

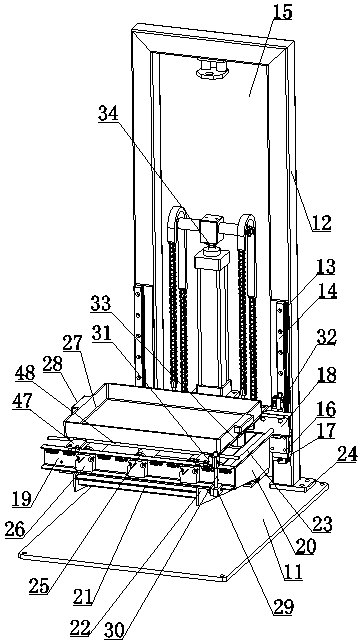

Automatic paper feeding machine

ActiveCN103818747AReduce labor intensityImprove paper feeding efficiencyArticle feedersAdverse effectScale type

The invention discloses an automatic paper feeding machine comprising a paper stack placing table for conveying paper stacks at intervals and a scale transfer table for unfolding paper stacks into scales conveyed out. An output end of the paper stack placing table is arranged opposite to an input end of the scale transfer table, an output end of the scale transfer table is arranged opposite to an input end of a printing packaging machine, and the paper stack placing table and the scale transfer table are connected with a master control device. A plurality of paper stacks can be fed at one time and are unfolded sequentially into scale typed paper to convey into the printing packaging machine to continuously feed the paper , paper feeding speed is high, no manual watching and frequent feeding are required, labor intensity of workers is greatly reduced, empty machine conditions of the printing packaging machine are avoided, paper feeding efficiency is high, and no adverse effect such as scratch on paper occurs.

Owner:HEBEI TIANYUHENG TECH CO LTD

Paper feeding structure for bearing packaging machine

PendingCN113788183AImprove paper feeding efficiencyIncrease productivityWrapping material feeding apparatusCardboardIndustrial engineering

The invention provides a paper feeding structure for a bearing packaging machine, and relates to the technical field of bearing packaging. The paper feeding structure for the bearing packaging machine comprises a support, a paper bearing plate, a paper absorbing assembly and a paper moving assembly, wherein the paper bearing plate is arranged on the support; the paper moving assembly is arranged on the support and located above the paper bearing plate; and the paper absorbing assembly is located on the paper moving assembly so that the paper moving assembly can drive the paper absorbing assembly to move forwards and upwards. Therefore, the technical effect of improving the working efficiency is achieved.

Owner:红米(宁波)智能装备有限公司

Automatic paper shredder

ActiveUS11090657B2Enhanced inhibitory effectImprove shredding efficiencyGrain treatmentsCartonElectric machinery

An automatic paper shredder includes a shredder cover, a paper holding box, a shell, a paper holding plate, a paper holding plate inlet, a paper shredding component, a drive motor, a paper pressing plate, a paper pick-up component, and a waste paper bin. The paper pressing effect is improved through a spliced paper pressing plate, and the paper pick-up effect is improved through a damping plate, a soft rubber piece, and a convex rib, and thus, efficiency is improved. The automatic paper shredder has the characteristics of being highly automated, convenient to use, safe, reliable, structurally simple and cost-effective.

Owner:AURORA OFFICE EQUIP

Vacuum transfer device for flatbed hot stamping die-cutting machine

ActiveCN103863858BEasy to adjust the number of opening and closingQuick responseArticle feedersPulp and paper industryMagnet

The invention relates to a vacuum paper feeding device for a flat pressing and planar gold stamping die cutting machine. The vacuum paper feeding device for the flat pressing and planar gold stamping die cutting machine comprises a vacuum drain body, a micropore cover plate, a lower cover plate, an upper retaining iron piece, a lower retaining iron piece, a permanent magnet valve core and an open and close permanent magnet; the upper retaining iron piece is fixed on the micropore cover plate; the lower retaining iron piece is fixed on the lower cover plate; a vacuum micropore channel, a branch vacuum channel, a main vacuum channel and a vacuum outlet which are communicated sequentially are arranged in the vacuum drain body; a micropore group which is communicated with the vacuum micropore channel is formed in the micropore cover plate; the open and close permanent magnet is arranged corresponding to the permanent magnet valve core which is arranged in the vacuum drain body. Compared with the prior art, vacuum paper feeding device for the flat pressing and planar gold stamping die cutting machine has the advantages of being quick in response speed, high in paper feeding quality and paper feeding efficiency, enabling the number of open paper sucking micro pores and the number of closed paper sucking micro pores to be conveniently adjusted, being not prone to scratch papers in a paper feeding process and the like.

Owner:SHANGHAI ETERNAL MACHINERY

Paper feeding device based on composite paper

PendingCN113651165APositioning movement positionReduce the phenomenon of double sheetsArticle deliveryCardboardControl engineering

The invention discloses a paper feeding device based on composite paper. The paper feeding mechanism comprises a driving device, a paper twisting device and a flow guiding device; the driving device is erected on a support erected on a bottom plate, and a paper feeding platform located below the paper twisting device is further erected on the support; the paper twisting device comprises an inclined paper twisting plate, and further comprises a pre-paper twisting wheel, an upper paper twisting wheel and a lower paper twisting wheel which are driven by the driving device; the pre-paper twisting wheel is located above the paper feeding platform, and the upper paper twisting wheel and the lower paper twisting wheel are located above and below the paper twisting plate respectively; the paper twisting plate is arranged between the paper feeding platform and the flow guiding device; a paper feeding area is arranged above the paper feeding platform, and a storage area is arranged below the paper feeding platform; and a paper placing mechanism comprises a lifting translation device and a placing platform, the lifting translation device is connected to the placing platform, and the placing platform is driven by the lifting translation device to move back and forth in the storage area and the paper placing area which is connected to the paper feeding area. The paper feeding device based on the composite paper is high in practicability.

Owner:SUZHOU DEQI INTELLIGENT TECH CO LTD

Automatic paper shredder

ActiveUS20200276594A1Enhanced inhibitory effectImprove shredding efficiencyGrain treatmentsCardboardPaper dust

An automatic paper shredder includes a shredder cover, a paper holding box, a shell, a paper holding plate, a paper holding plate inlet, a paper shredding component, a drive motor, a paper pressing plate, a paper pick-up component, and a waste paper bin. The paper pressing effect is improved through a spliced paper pressing plate, and the paper pick-up effect is improved through a damping plate, a soft rubber piece, and a convex rib, and thus, efficiency is improved. The automatic paper shredder has the characteristics of being highly automated, convenient to use, safe, reliable, structurally simple and cost-effective.

Owner:AURORA OFFICE EQUIP

Automatic paper feeding mechanism of digital creasing machine

InactiveCN103612926BAvoid damageRealize automatic paper feeding operationArticle separationPulp and paper industryPaper sheet

Owner:NINGBO RONGHUA OFFICE EQUIP

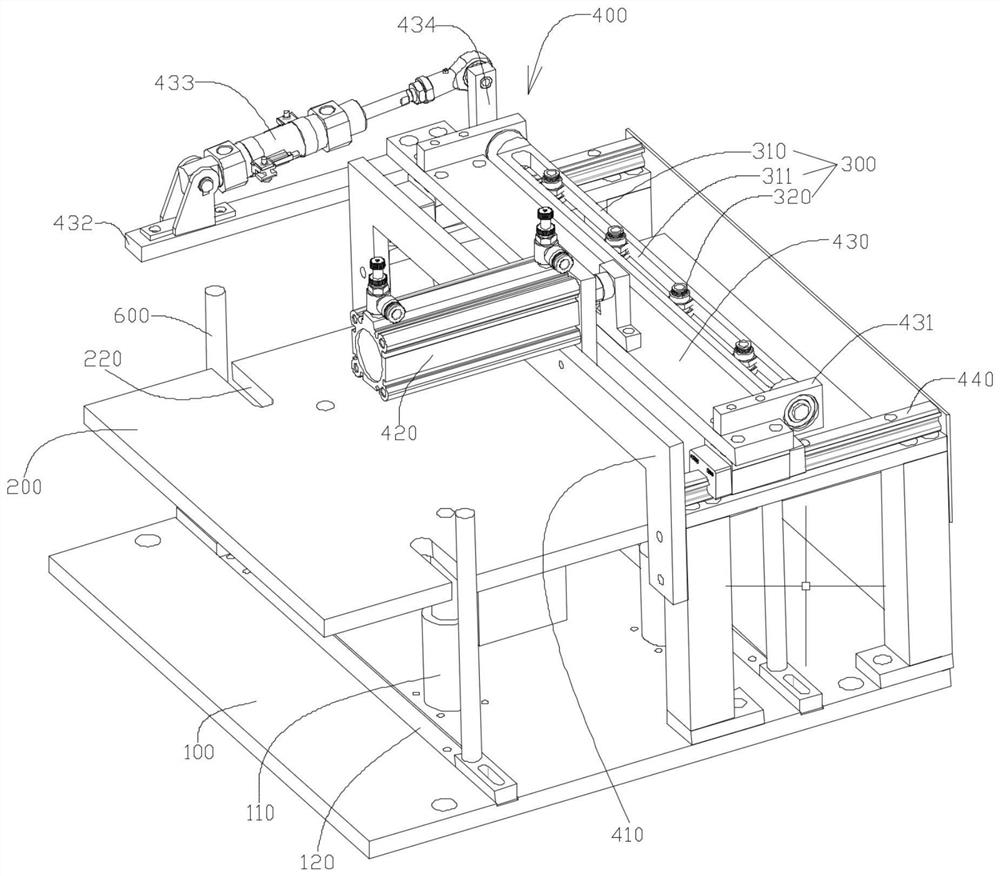

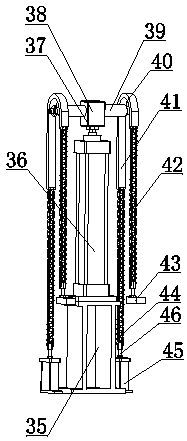

A chain-driven coated paper lifting and conveying device for a paper feeder

ActiveCN107585605BConvenient vertical lift controlEasy slide adjustmentArticle separationPulp and paper industryChain drive

The invention discloses a chain-driven coated paper lifting and conveying device used for a paper conveying machine. The device comprises a base plate, the base plate is provided with a bracket, the two sides of the bracket are provided with fixing plates, and each fixing plate is provided with a guide rail; a slot is formed in the bracket; movable bases are arranged on the guide rails, a buttingtrack is arranged between the movable bases, the outer side of the butting track is provided with an outer-side track, and butting bases are arranged between the outer-side track and the two ends of the butting track; a plurality of supporting rollers are arranged between the outer-side track and the butting track; a paper loading frame is arranged between the outer-side track and the butting track and installed on the supporting rollers; a lifting mechanism is arranged on the base plate. According to the chain-driven coated paper lifting and conveying device, the vertical lifting movement ofthe butting track is achieved, the stable movement adjustment of the butting track along the guide rails is achieved through the movable bases, and therefore the vertical lifting control over the paper loading frame can be conveniently conducted; the lifting and conveying device for the paper conveying machine is placed in front of the paper conveying machine and can convey coated paper to the paper conveying machine through the paper loading frame, and the paper conveying efficiency is greatly improved.

Owner:重庆市国丰印务有限责任公司

Paper feeding travel lengthening device

The invention discloses a paper feeding travel lengthening device. The paper feeding travel lengthening device comprises a bracket, and a first transmission roller, a second transmission roller and athird transmission roller arranged at the upper part of the bracket in parallel at equal intervals, and a fourth transmission roller, a fifth transmission roller, a sixth transmission roller and a paper discharge roller arranged at the lower part of the bracket in parallel at equal intervals; the first transmission roller, the second transmission roller and the third transmission roller are the same in height; the heights of the fourth transmission roller, the fifth transmission roller and the sixth transmission roller are gradually increased; the paper discharge roller is as high as the fourth transmission roller; and the fourth transmission roller, the fifth transmission roller and the sixth transmission roller are respectively positioned rightly below the first transmission roller, thesecond transmission roller and the third transmission roller. The paper feeding travel lengthening device is additionally mounted in front of a slitting machine, and can lengthen a paper feeding travel in front of the slitting machine to a proper size according to different paper demands, so that the paper feeding stability is improved, and the later way rectification is reduced.

Owner:ZHEJIANG WELLVAST PACKING PRINTING PRODS

Automatic paper loader

ActiveCN103818747BWon't scratchReduce labor intensityArticle feedersUltimate tensile strengthAdverse effect

The invention discloses an automatic paper feeding machine comprising a paper stack placing table for conveying paper stacks at intervals and a scale transfer table for unfolding paper stacks into scales conveyed out. An output end of the paper stack placing table is arranged opposite to an input end of the scale transfer table, an output end of the scale transfer table is arranged opposite to an input end of a printing packaging machine, and the paper stack placing table and the scale transfer table are connected with a master control device. A plurality of paper stacks can be fed at one time and are unfolded sequentially into scale typed paper to convey into the printing packaging machine to continuously feed the paper , paper feeding speed is high, no manual watching and frequent feeding are required, labor intensity of workers is greatly reduced, empty machine conditions of the printing packaging machine are avoided, paper feeding efficiency is high, and no adverse effect such as scratch on paper occurs.

Owner:HEBEI TIANYUHENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com