Vacuum paper feeding device for flat pressing and planar gold stamping die cutting machine

A flattening and vacuum technology, applied in the field of vacuum paper transfer device, can solve the problems of low work efficiency, high price, complex structure, etc., and achieve the effect of fast response, high paper feeding efficiency and high paper feeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

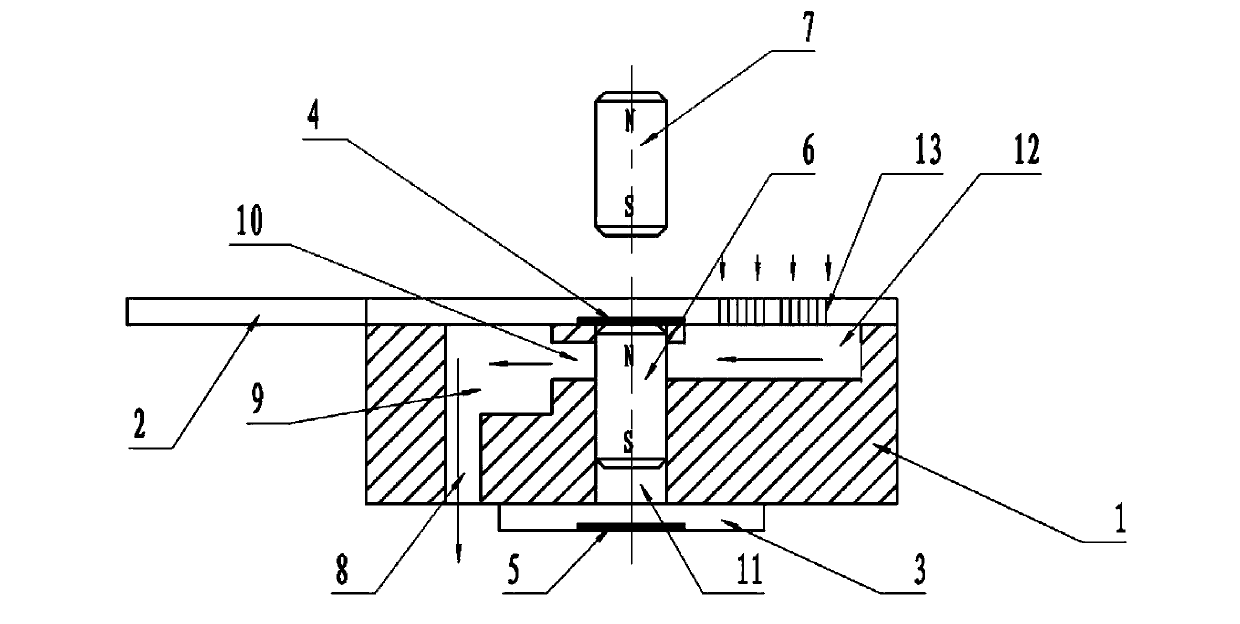

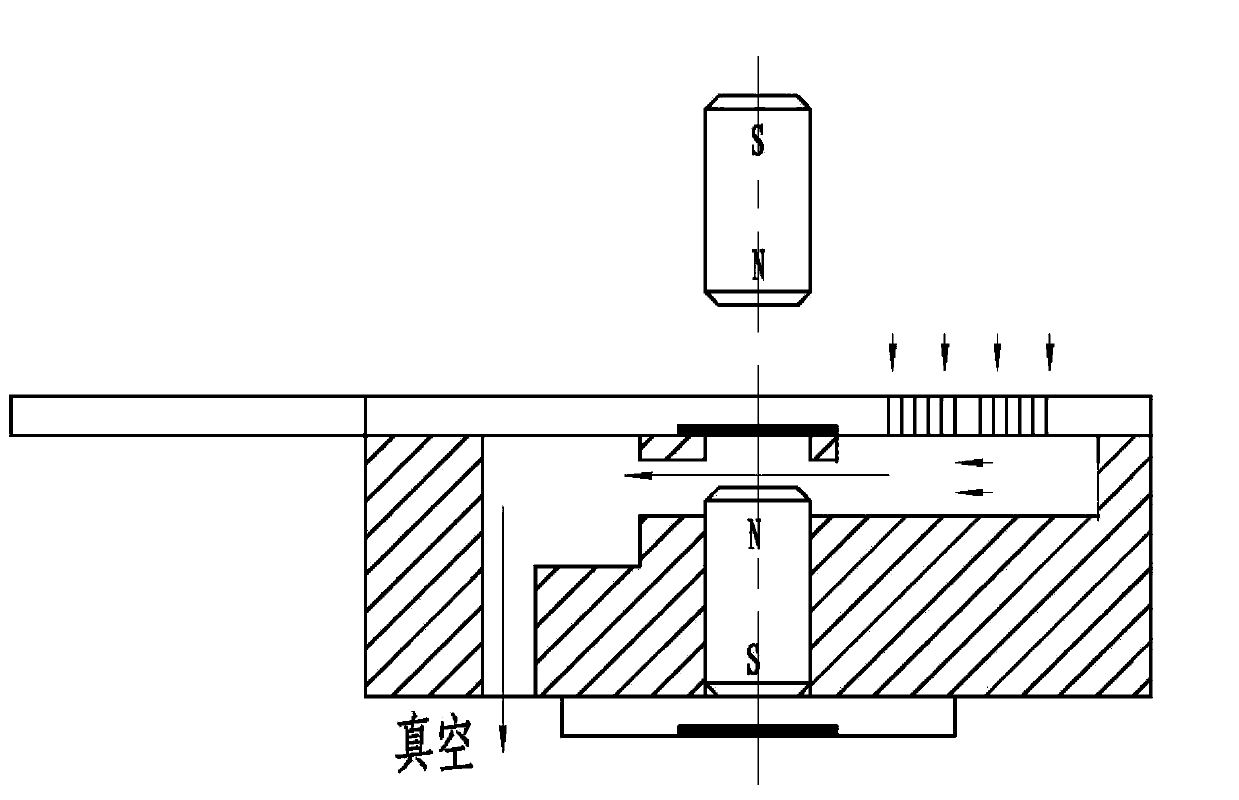

[0018] Such as figure 1 , figure 2 As shown, a vacuum paper transfer device for a flat stamping die-cutting machine, including a vacuum discharge body 1, a microporous cover plate 2, a lower cover plate 3, an upper holding iron sheet 4, a lower holding iron sheet 5, a permanent The magnetic valve core 6 and the opening and closing permanent magnet 7, the upper holding iron sheet 4 is fixed on the microporous cover plate 2, the lower holding iron sheet 5 is fixed on the lower cover plate 3, and the vacuum discharge body 1 There are vacuum microporous passages 12, branch vacuum passages 10, main vacuum passages 9 and vacuum outlets 8 connected in sequence, and the microporous cover plate 2 is provided with micropore groups 13 communicating with the vacuum microporous passages 12, The opening and closing permanent magnet 7 is arranged corresponding to the permanent magnet valve core 6, and the permanent magnet valve core 6 is arranged in the vacuum discharge body 1;

[0019] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com