Paper feed machine for product check machine and paper feed method thereof

A product inspection machine and paper feeding technology, applied in the direction of object supply, object separation, pile separation, etc., can solve the problems of scrapping of qualified printed matter, poor surface wear resistance, false detection, etc., to avoid false detection, high paper feeding efficiency, The effect of uninterrupted paper feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

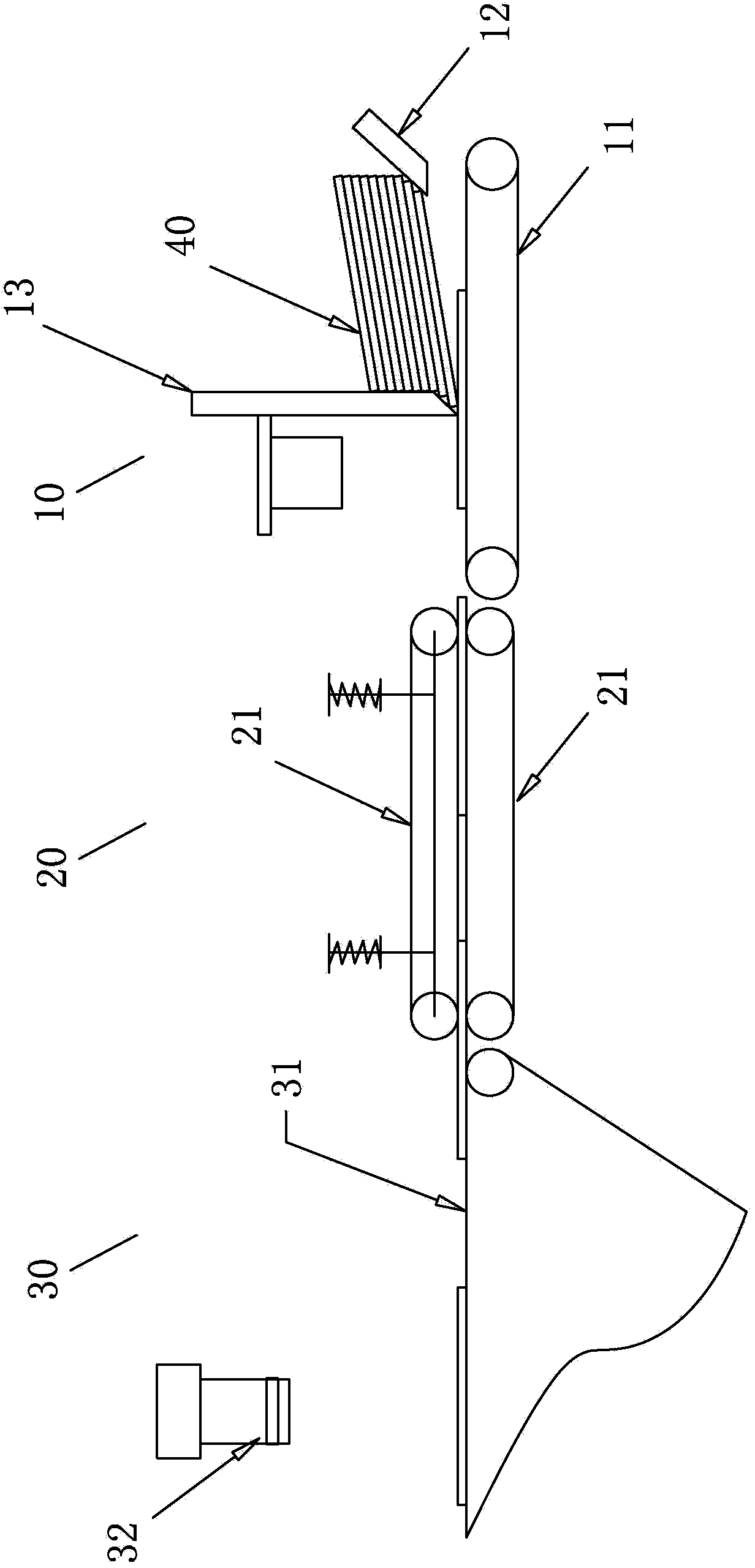

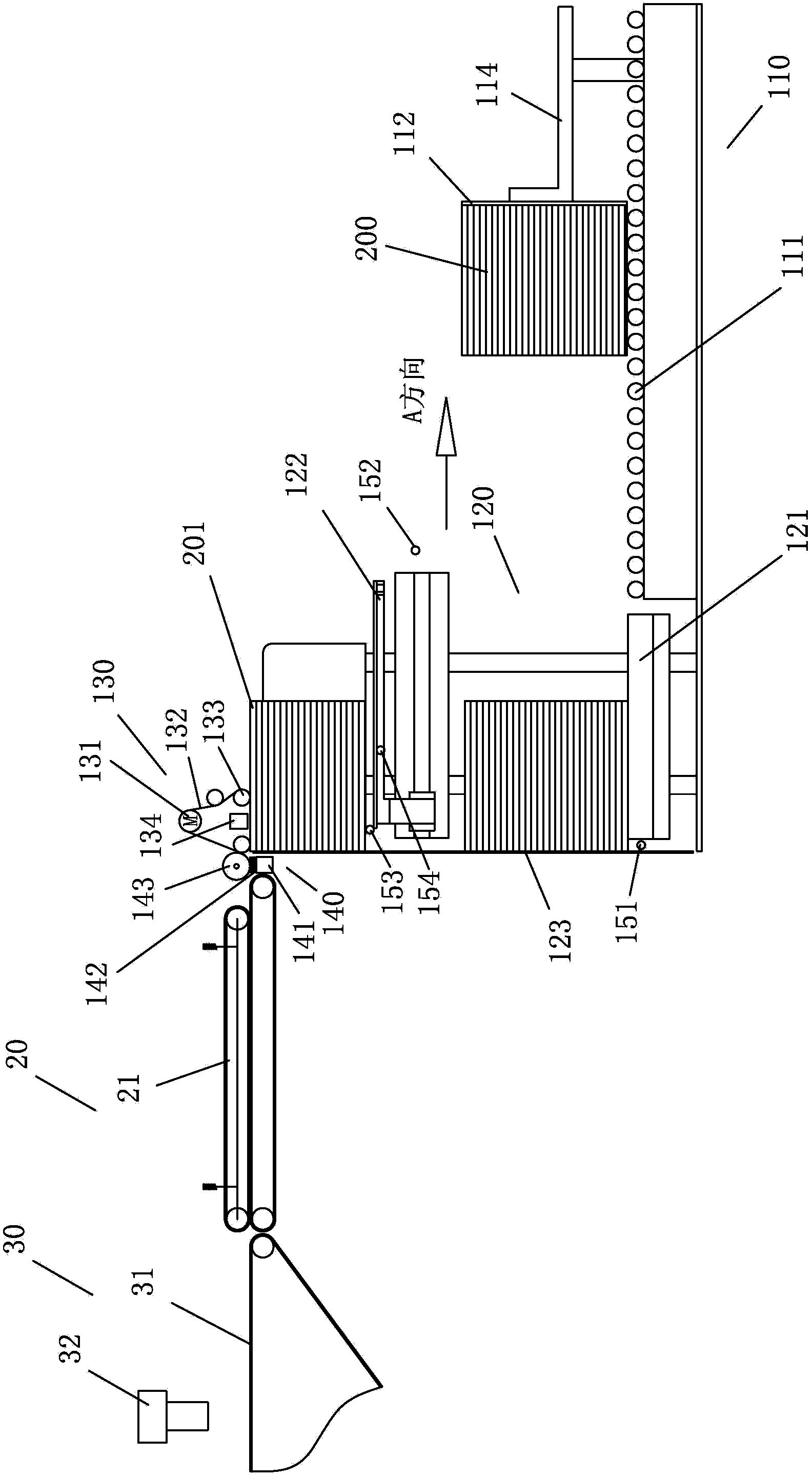

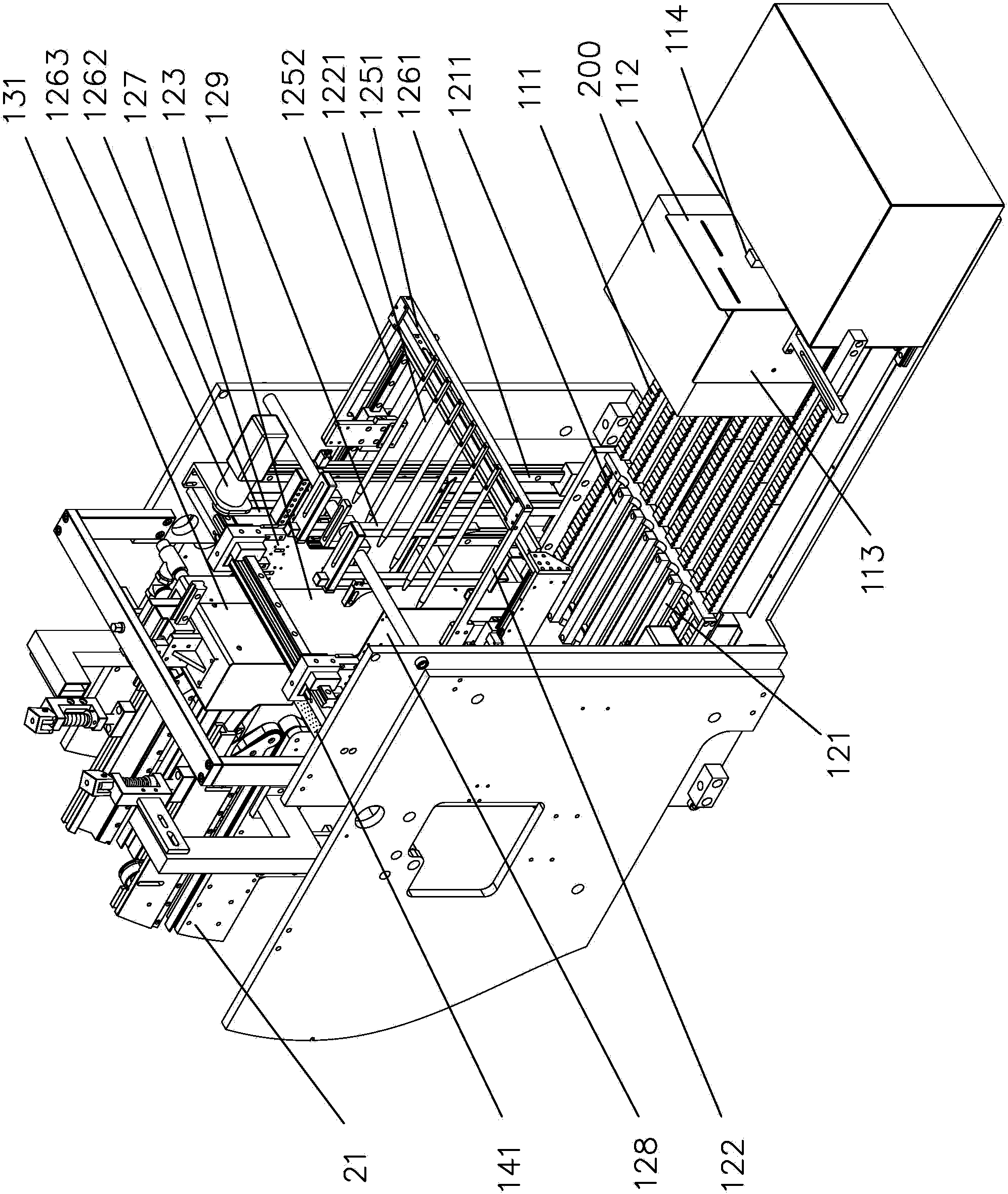

[0030] The paper feeder of the present invention is used as a product inspection machine, also known as a small-sheet printed product inspection machine.

[0031] Such as figure 2 and image 3 As shown, the paper feeder for the product inspection machine of the present invention includes an uninterrupted paper feeding mechanism 120, and above the upper paper output end of the uninterrupted paper feeding mechanism 120, a suction paper feeding mechanism 130 is correspondingly provided to absorb the conveyance of a single printed matter. On one side of the uninterrupted paper feeding mechanism 120, a paper flushing board 123 is vertically arranged corresponding to the output end of the air suction paper feeding mechanism 130, and the output end of the air suction paper feeding mechanism 130 is connected with the single printed matter from the air suction paper feeding mechanism 130. The input end of the air blowing paper separation mechanism 140 that is separated and conveyed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com