Paper feeding mechanism of a cardboard laminating machine

A technology of a paper feeding mechanism and a laminating machine, which is applied in the directions of separating objects, supplying objects, positioning objects, etc., can solve the effect of the efficiency of the cardboard laminating machine, the influence of the operator's proficiency, and the difficulty of manual cardboard laminating machine operation. and other problems, to achieve the effect of simple and reasonable structure, convenient paper feeding, and stable paper feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

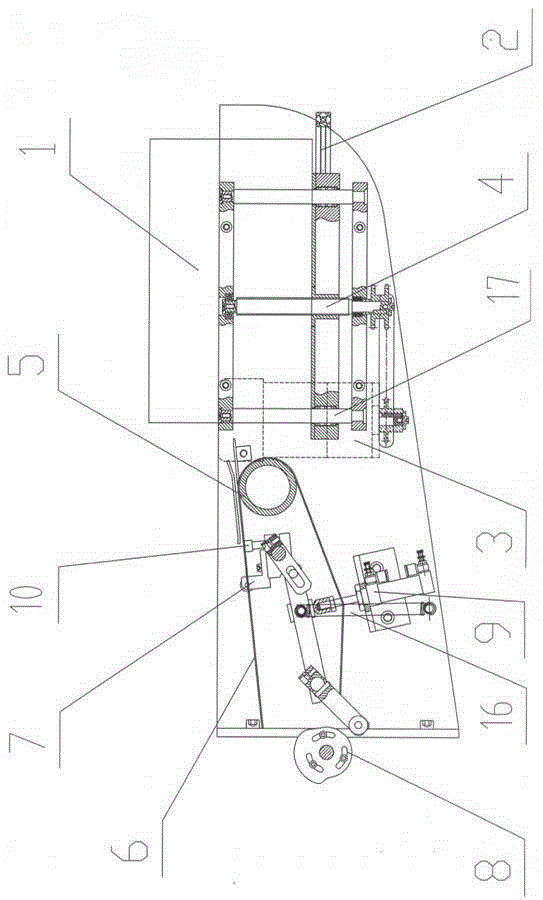

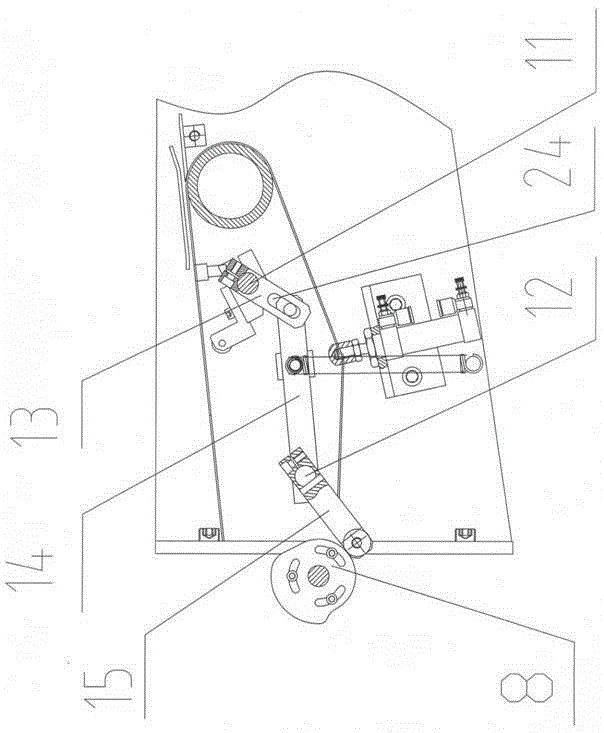

[0020] Referring to accompanying drawing, the paper feeding mechanism of a kind of cardboard laminating machine in this specific embodiment comprises frame, and described frame is provided with the conveyer belt 6 of band power source transmission (conveyor belt can adopt belt, can put The belt is wound on the conveying roller 5, and the conveying roller is set on the frame, and then the motor is set as the power source to drive the conveying roller, and then the belt moves; the length and speed of the conveying belt are set according to the actual situation), and the conveying outlet of the conveying belt faces the card The main machine of the paper laminating machine, the conveying outlet faces the main machine (not shown in the figure of the main machine). The conveyor belts are at least two, and the conveyor belts are separated from each other, and the space separated between the conveyor belts is provided with a stop gauge 7 that moves up and down. The stop gauge can have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com