Paper feeder of die-cutting machine

A die-cutting machine and paper feeding technology, which is applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems that the paper feeding direction cannot be adjusted, the guiding effect is not ideal, and the paper thickness requirement is high, so as to improve the paper feeding efficiency , strong practicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

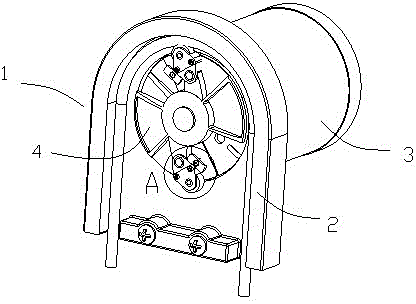

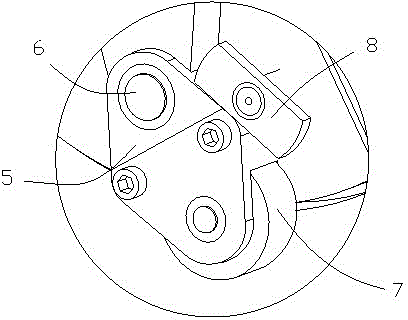

[0016] Such as Figure 1 to Figure 2 As shown, the paper feeder 1 of the die-cutting machine of the present invention includes a drive motor 3 and a guide groove housing 2, the head of the drive motor 3 is provided with a rotatable guide disc 4, and the bottom of the guide disc 4 A rotatable guide bracket 5 is provided, the tail of the guide bracket 5 is provided with a fixed pivot 6, the head of the guide bracket 5 is provided with a guide rubber wheel 7, and the guide disc 4 is provided with a rotatable bead 8.

[0017] Bead 8 is made of nylon.

[0018] The above is only a specific implementation of the present invention, but the scope of prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com