Paper feeding travel lengthening device

A technology for extending device and stroke, which is applied in the field of paper-feeding stroke extension device, which can solve the problems of high requirements for deviation correcting device, insufficient product precision, and insufficient use effect, so as to achieve the effect of improving quality, improving efficiency, and reducing deviation in the rear line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

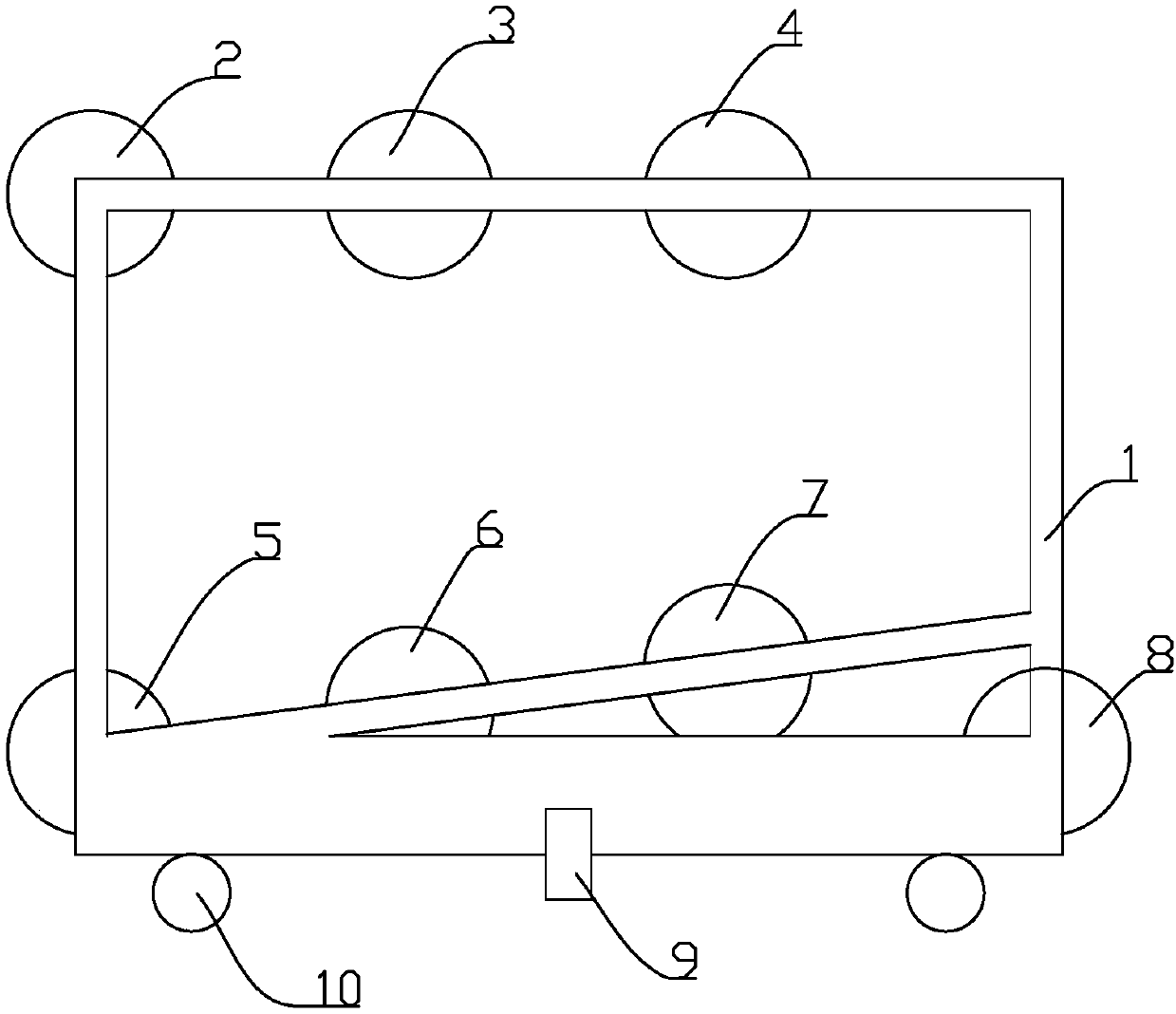

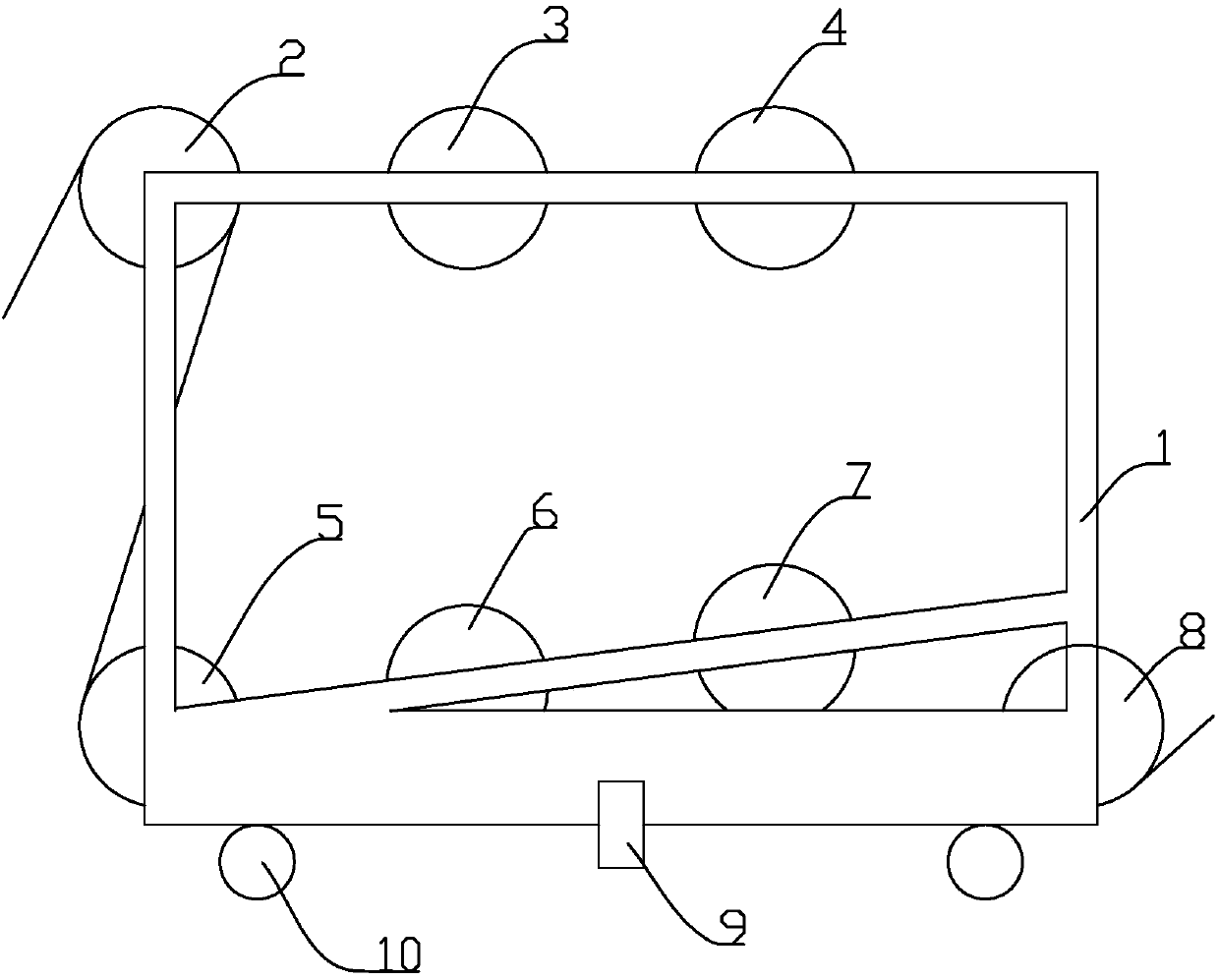

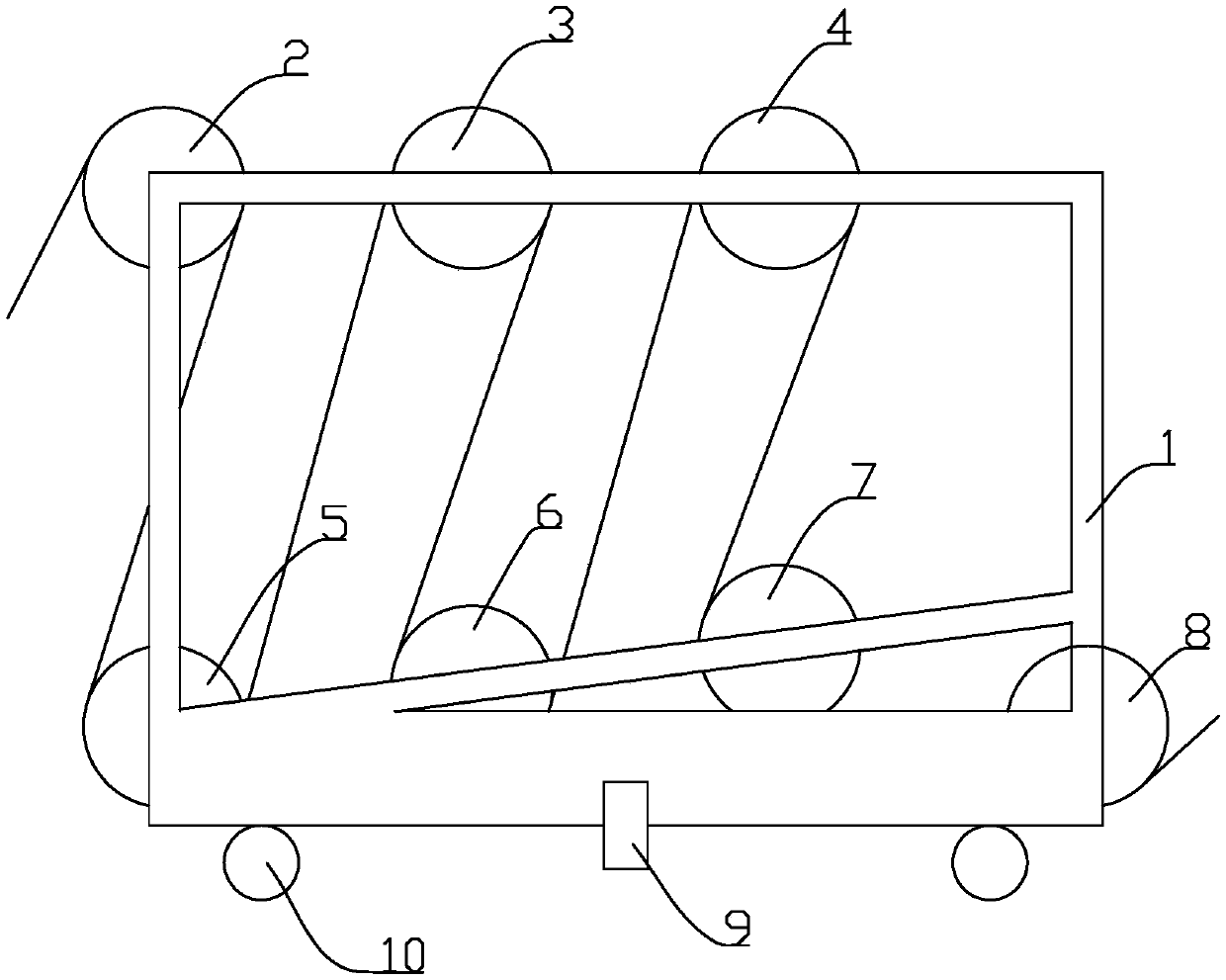

[0018] Such as Figure 1-3 As shown, a device for extending the paper travel stroke includes a support 1, and the first transmission roller 2, the second transmission roller 3 and the third transmission roller 4 arranged in parallel on the upper part of the support 1 at equal intervals, and arranged in parallel at equal intervals on the support 1 The fourth transmission roller 5, the fifth transmission roller 6, the sixth transmission roller 7 and the paper output roller 8 in the lower part, the first transmission roller 2, the second transmission roller 3 and the third transmission roller 4 are equal in height, and the The heights of the fourth transmission roller 5, the fifth transmission roller 6 and the sixth transmission roller 7 gradually increase, and the height of the paper output roller 8 is equal to the height of the fourth transmission roller 5, and the fourth transmission roller 5, The fifth transmission roller 6 and the sixth transmission roller 7 are located dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com