Paper feeding device based on composite paper

A paper feeding device and paper technology, applied in the directions of sending objects, transportation and packaging, thin material handling, etc., can solve the problems of reduced overall efficiency, difficulty in realizing high-intensity automated processes, etc., and achieve rack optimization and strong inclusiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

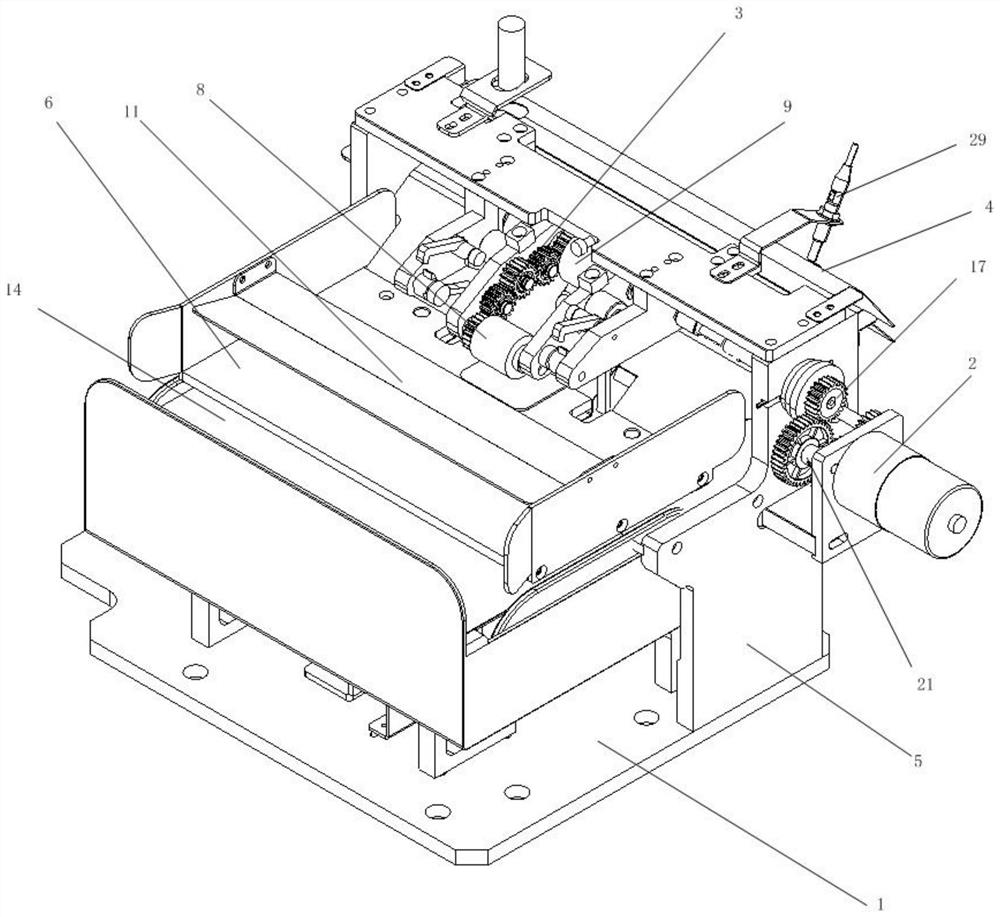

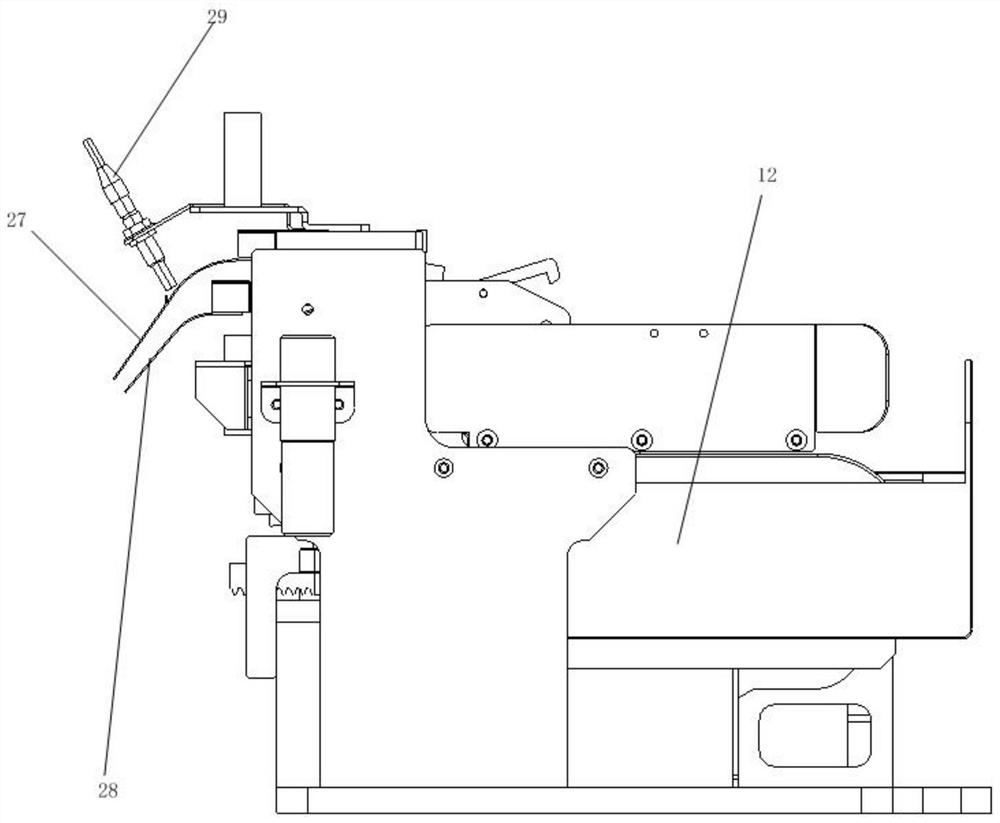

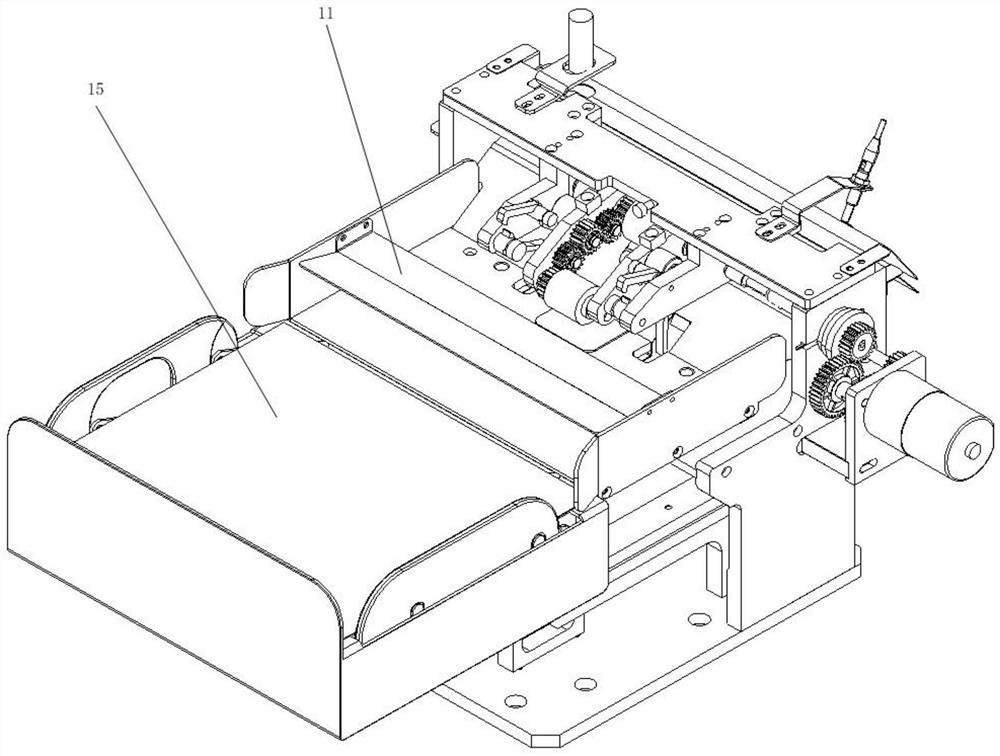

[0062] In this specific example Figure 5 to Figure 7 The shown paper feeding device based on composite paper includes a paper feeding mechanism and a paper feeding mechanism located on the bottom plate 1. The paper feeding mechanism includes a driving device 2, a paper pickup device 3 and a flow guiding device 4. The driving device 2 is erected on the Standing on the support 5 on the bottom plate 1, the support 5 is also erected with a paper feeding platform 6 located below the paper pickup device 3. The paper pickup device 3 includes an inclined pickup board 7 and a forwarding roller 8 driven by the drive device 2 , the upper pickup roller 9 and the lower pickup roller 10, the forward pickup roller 8 is located above the paper feeding platform 6, the pickup direction of the forward pickup roller 8 and the upper pickup roller 9 is the same, and the upper pickup with the opposite pickup direction The paper roller 9 and the lower pickup roller 10 are respectively located above ...

Embodiment 2

[0066] In this specific example Figure 5 to Figure 7 The paper feeding mechanism of a composite paper-based paper feeding device shown includes a paper feeding mechanism and a paper feeding mechanism located on the bottom plate 1. The paper feeding mechanism includes a driving device 2, a paper pickup device 3 and a flow guiding device 4. The device 2 is set up on the support 5 standing on the base plate 1, and the support 5 is also set up with a paper feeding platform 6 located below the paper pickup device 3. The pickup roller 8, the upper pickup roller 9 and the lower pickup roller 10, the forward pickup roller 8 are located above the paper feeding platform 6, the pickup direction of the forward pickup roller 8 and the upper pickup roller 9 is the same, and the pickup direction The opposite upper pickup roller 9 and the lower pickup roller 10 are located above and below the pickup board 7 respectively, and the pickup board 7 is arranged between the paper feeding platform 6...

Embodiment 3

[0070] In this specific example Figure 5 to Figure 7 The paper feeding mechanism of a composite paper-based paper feeding device shown includes a paper feeding mechanism and a paper feeding mechanism located on the bottom plate 1. The paper feeding mechanism includes a driving device 2, a paper pickup device 3 and a flow guiding device 4. The device 2 is set up on the support 5 standing on the base plate 1, and the support 5 is also set up with a paper feeding platform 6 located below the paper pickup device 3. The pickup roller 8, the upper pickup roller 9 and the lower pickup roller 10, the forward pickup roller 8 are located above the paper feeding platform 6, the pickup direction of the forward pickup roller 8 and the upper pickup roller 9 is the same, and the pickup direction The opposite upper pickup roller 9 and the lower pickup roller 10 are located above and below the pickup board 7 respectively, and the pickup board 7 is arranged between the paper feeding platform 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com