Leading edge feeder for corrugated cardboard printing equipment

A technology of printing equipment and corrugated paper, which is applied to general parts of printing machinery, printing, printing machines, etc., can solve problems such as inability to start and stop quickly, and achieve the effects of inability to start and stop quickly, small vibration, and stable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

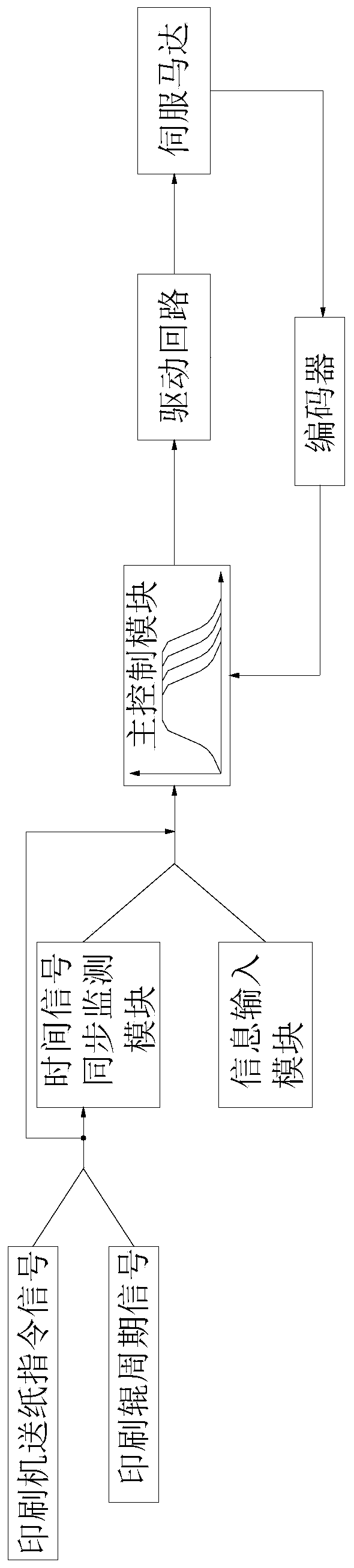

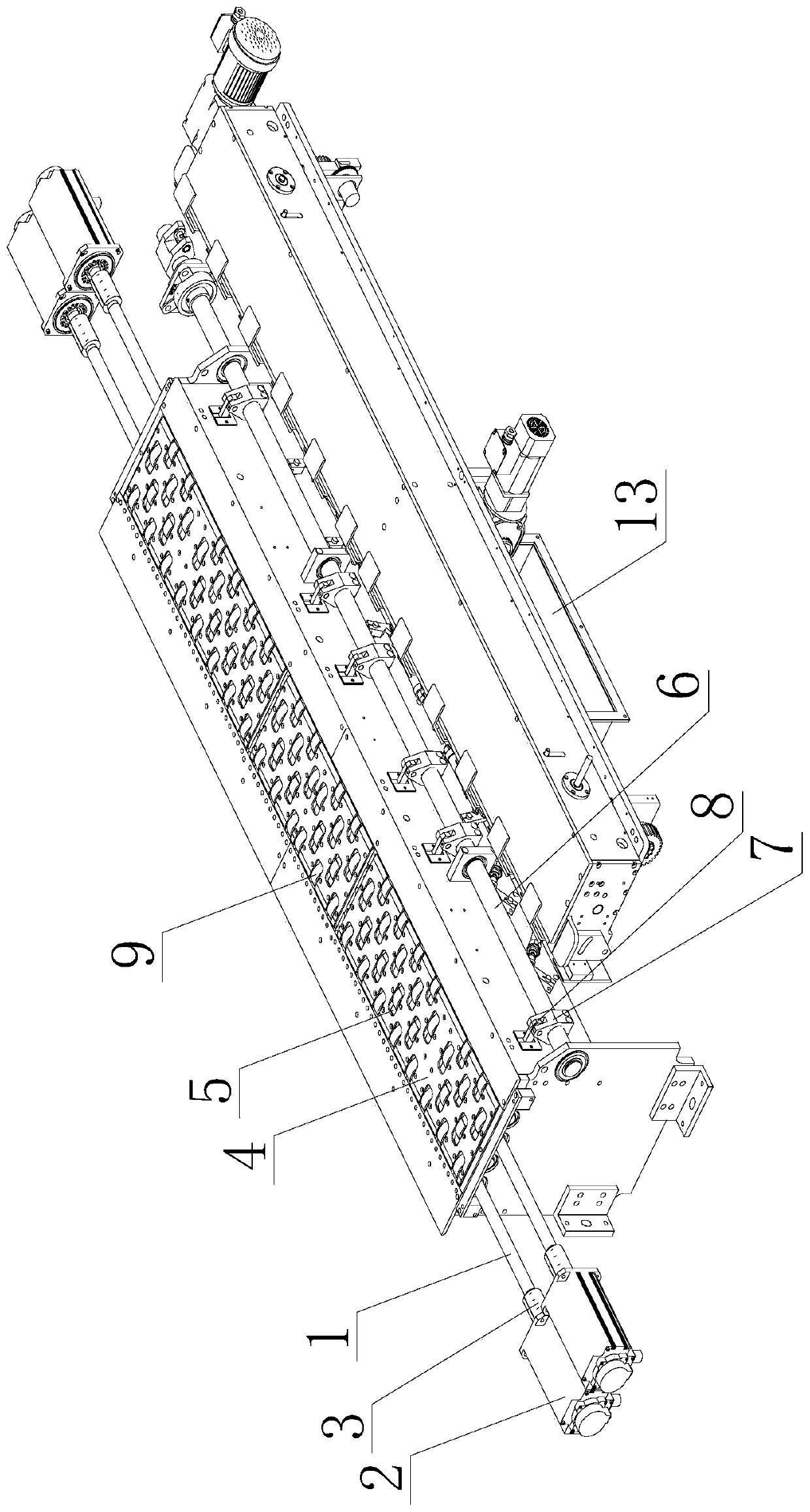

[0042] In this embodiment, a driving device for the leading edge paper feeding part of corrugated paper printing equipment includes a servo motor, a coupling and a main control device, such as image 3 or Figure 5 As shown, each paper feeding shaft 1 in the leading edge paper feeding part is correspondingly equipped with a servo motor 2, and the output shaft of each servo motor is connected to a paper feeding shaft through a coupling 3, and each servo motor is connected to the main shaft respectively. control device connection;

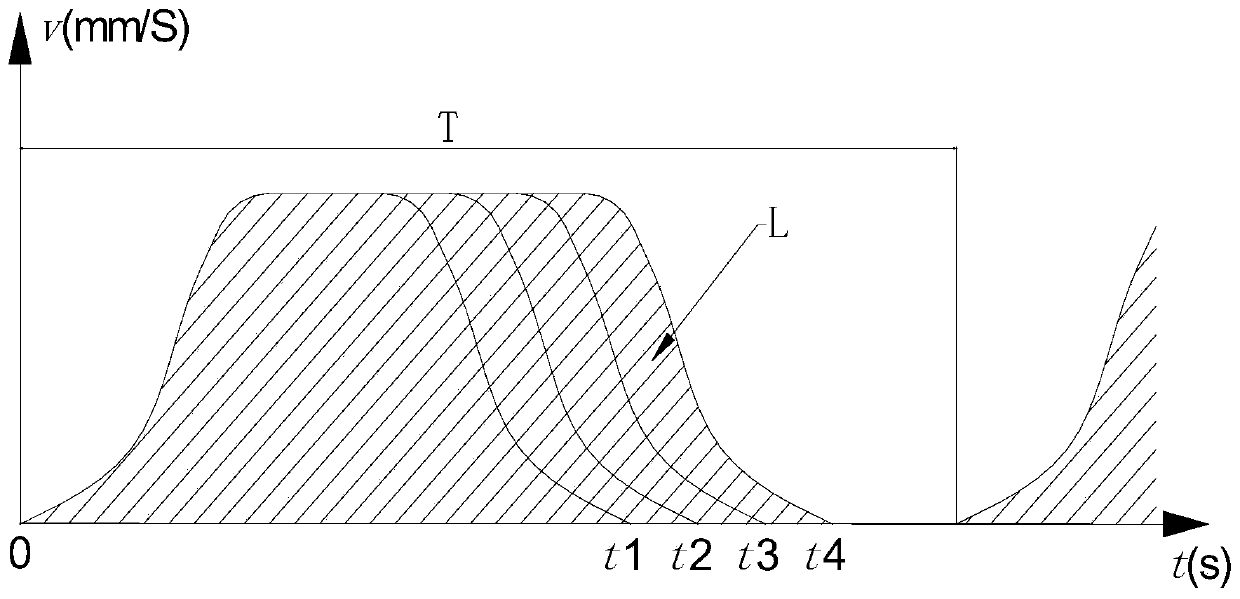

[0043] Such as figure 1 As shown, the main control device is equipped with a time signal synchronization monitoring module, an information input module, a main control module, a drive circuit and an encoder. The signal synchronization monitoring module and the information input module are connected to the main control module respectively, and the main control module passes through the drive circuit Connect each servo motor, and each servo motor is ...

Embodiment 2

[0054] In this embodiment, a leading edge paper feeding unit for corrugated printing equipment with the driving device described in Embodiment 1, such as image 3 As shown, it includes a paper feeding platform and a lifting mechanism. The top surface of the paper feeding platform is a lifting plate 4, and wheel holes 5 are distributed on the lifting plate. The bottom of the lifting plate is connected with the lifting mechanism; A plurality of paper feed shafts 1, each paper feed shaft is provided with a plurality of paper feed wheels 9, each paper feed shaft is arranged under the lifting plate in parallel, and each paper feeding wheel is correspondingly located in a wheel hole; Driven by the lifting mechanism, the lifting movement is carried out; one end of each paper feeding shaft is independently provided with a servo motor 2, and the servo motor is connected to the paper feeding shaft through a coupling 3.

[0055] Lifting plate lifting mechanism includes swinging main shaf...

Embodiment 3

[0058] In this embodiment, a leading edge paper feeding unit for corrugated printing equipment with the driving device described in Embodiment 1, such as Figure 5 or Image 6As shown, it includes a paper feeding platform and a paper supporting mechanism. The paper supporting mechanism is a swing lifting structure, including a push rod 14, a fence rod 15, a swing connecting rod 16, a transmission block 17 and a swing main shaft 6. The swing main shaft is set on the paper feeding On the outside of the platform, the transmission block is fixedly connected to the swing spindle, one end of the swing link is hinged to the drive block, the other end of the swing link is hinged to the ejector rod, the other end of the ejector rod is hinged to the paper feeding platform, and multiple fence bars are distributed on the ejector rod On the surface of the paper feeding platform, there are multiple fence holes, and each fence rod is correspondingly located in a fence hole and moves up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com