Vacuum adsorption front edge paper feed unit in carton making linkage machine

A paper feeding unit and vacuum adsorption technology, applied in paper/cardboard containers, container manufacturing machinery, containers, etc., can solve the problems of high price, slow paper feeding, cardboard feeding, etc., and achieve low manufacturing cost and paper feeding speed. Quick, easy-to-understand effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

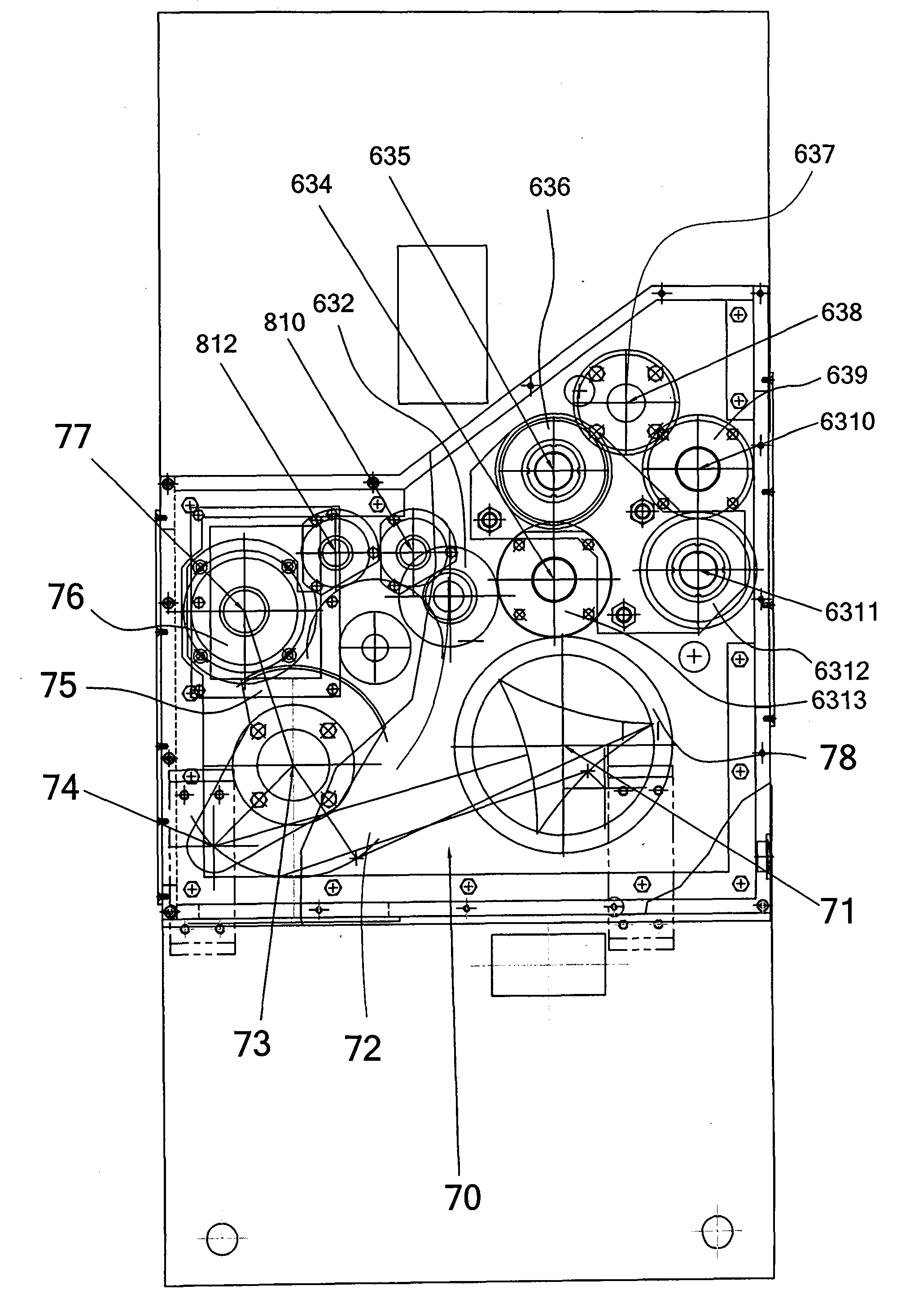

[0046] Embodiment 1, referring to Fig. 1-Fig. 3. The paper feed unit of the present embodiment comprises the machine table 50 of the paper feed unit, the manipulation control box 10, a main motor 61, the paper feed roller group 20 and the suction device 30, and also includes:

[0047] A transmission mechanism 60 that drives the paper feed roller (see Figure 4 ), which includes:

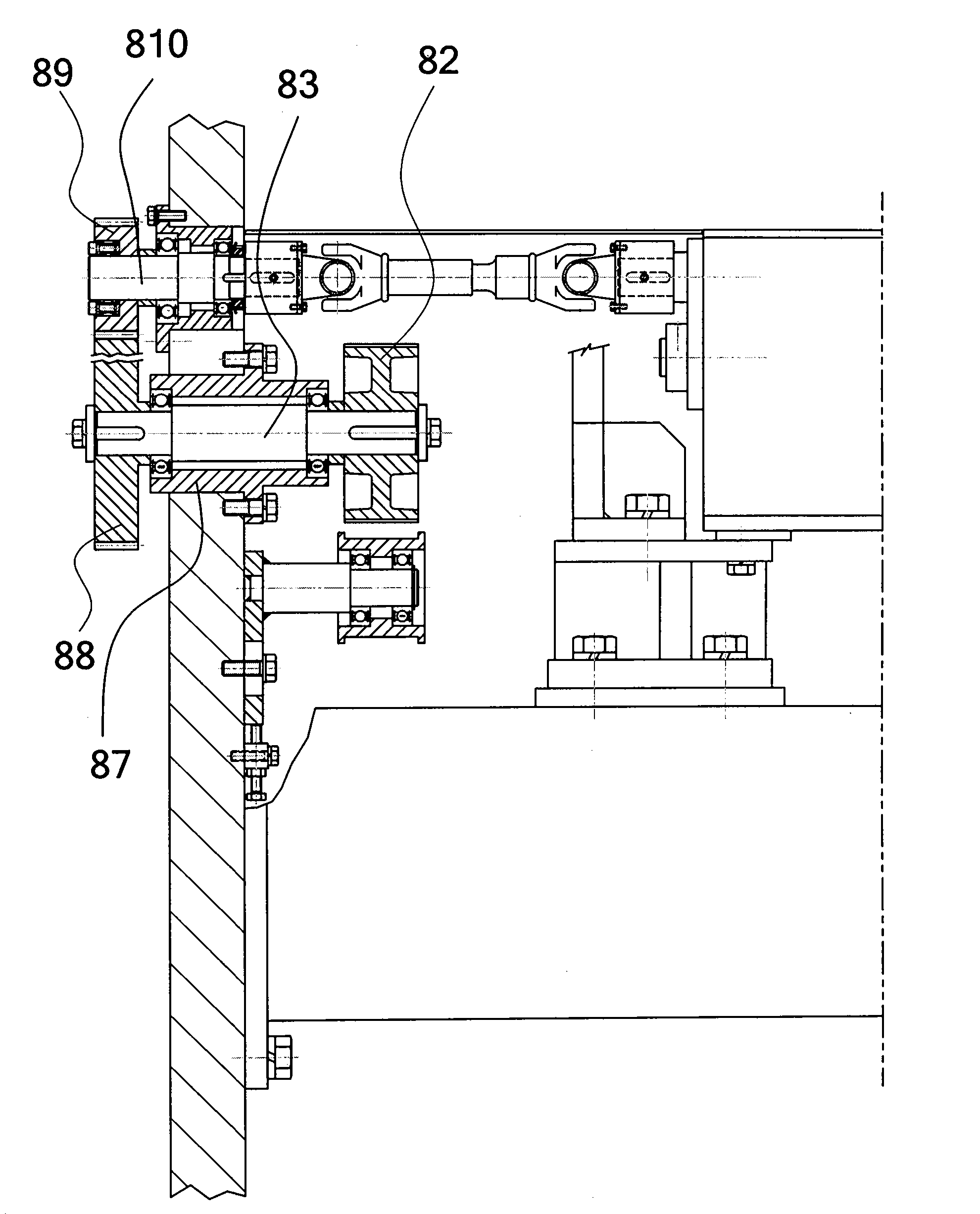

[0048] The pulley deceleration mechanism driven by the main motor 61, the deceleration mechanism includes a small pulley 65 mounted on the output shaft end of the main motor, a large pulley 66 and a transmission belt 62 mounted on the front end of the first drive shaft 67 described below (see Figure 5) ;

[0049] One first power transmission shaft 67, the rear end of this first power transmission shaft 67 is equipped with jaw coupling 672, links with the second power transmission shaft of the printing unit behind by this jaw coupling, this first A first synchronous pulley 671 is installed near the ...

Embodiment 2

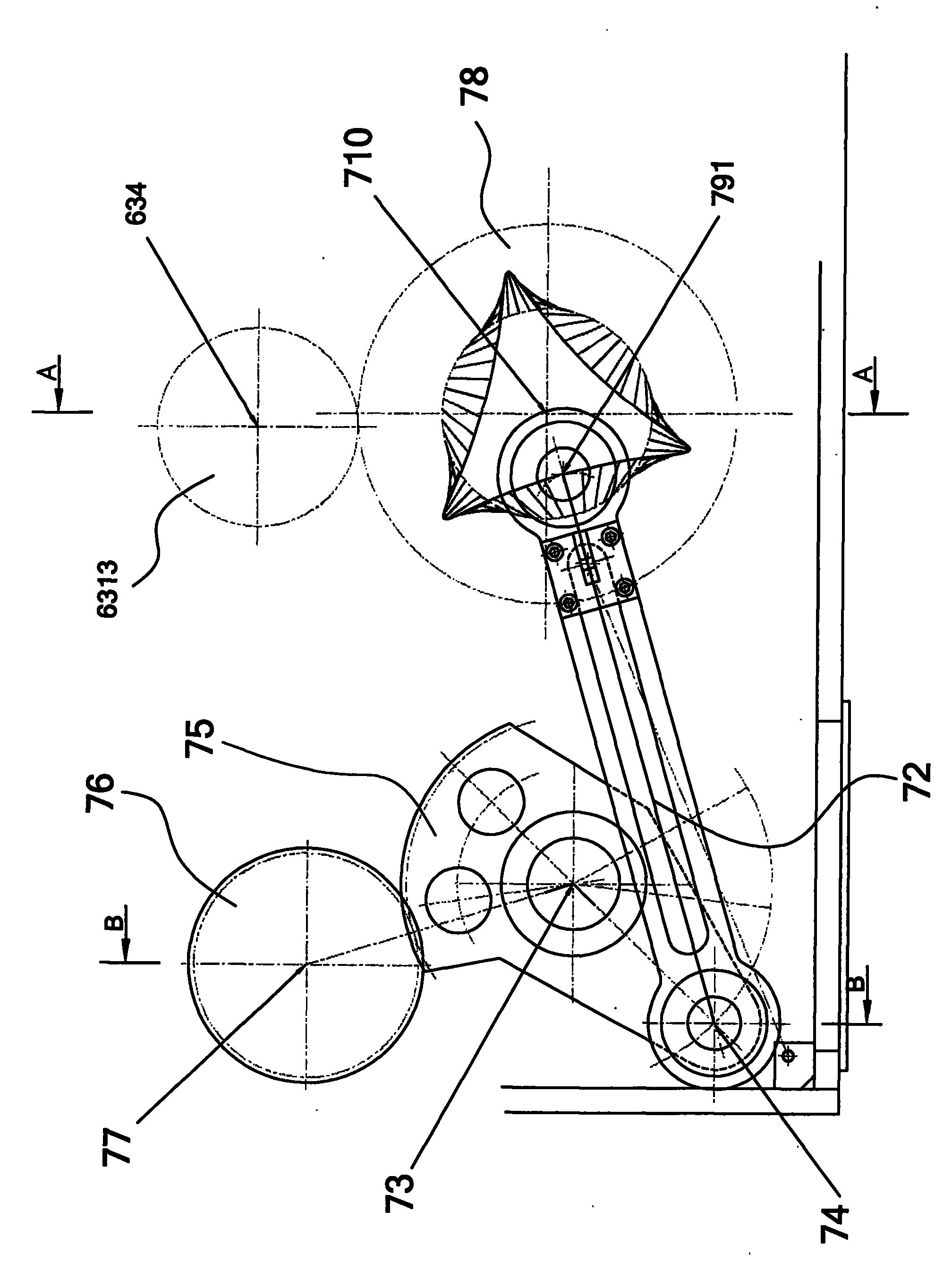

[0063] Embodiment 2, see again Figure 17 and Figure 12. This embodiment is based on the above-mentioned embodiment. In the said paper feeding belt reciprocating mechanism 70, it also includes a flange plate 711 with a boss. On the edge of the flange plate 711, 3 or 4 arc-shaped long slots 7111, the central angle a of each arc-shaped long slot 7111 is between 25°-35° (see Figure 16), the inner hole of the flange 711 is connected with the above-mentioned sleeve 713 through the key The tail parts are connected together, and 3-4 screw holes 7112 are also provided on its rim, and it is fixed on the right side plate 41 with screws. When the screw is loosened and the position of the arc-shaped long groove 7111 on the edge of the flange 711 is adjusted, the position of the large ring gear 710 relative to the pinion 714 can be adjusted accordingly, thereby adjusting the back and forth of the paper feeding belt 723 The swing angle is the central angle a.

Embodiment 3

[0064] Embodiment 3, refer to Fig. 16 again. In this embodiment, on the basis of the above two embodiments, the central angle a between the first fixed point 720 and the second fixed point 724 of a section of the part where the paper feeding belt 723 is wrapped on the large paper feeding pulley 719 The adjustment is 153°. Practice has proved that the central angle is the best.

[0065] Before work, the cardboard 90 is stacked on the machine platform 50 of the paper feeding unit, and the bottom of the machine platform is the suction box 40 . Then, start the motor of the main motor 61 and the air suction device, and the suction force of the air suction box 40 will firmly adsorb the lowermost cardboard 90 on the machine table. The main motor 61 drives the four paper feed rollers 21-24 to rotate through the above-mentioned transmission mechanism 60 for driving the paper feed rollers. Cams 811 and 813 rotate. When the cam lifted the lowermost cardboard 90 and was slightly highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com