Leather belt swinging feeder equipment of high-speed automatic cardboard printing forming machine

A forming machine and belt type technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of slow paper feeding speed and complex structure, and achieve the effect of fast paper feeding speed, simple structure and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

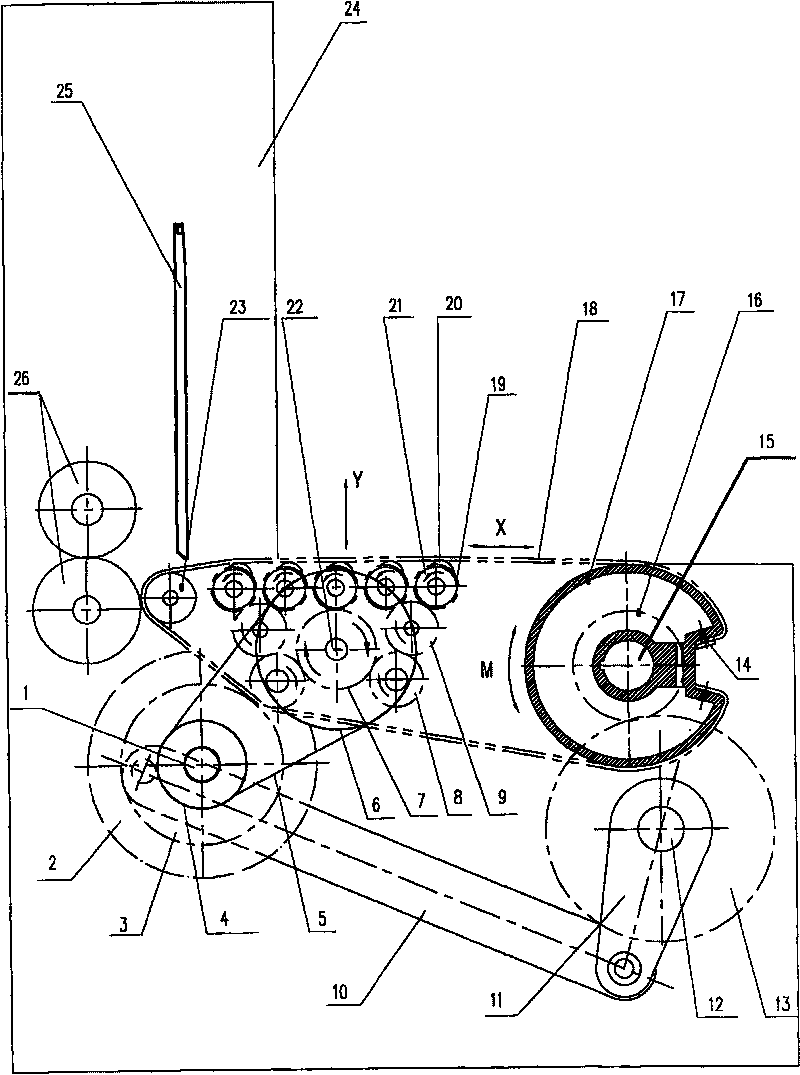

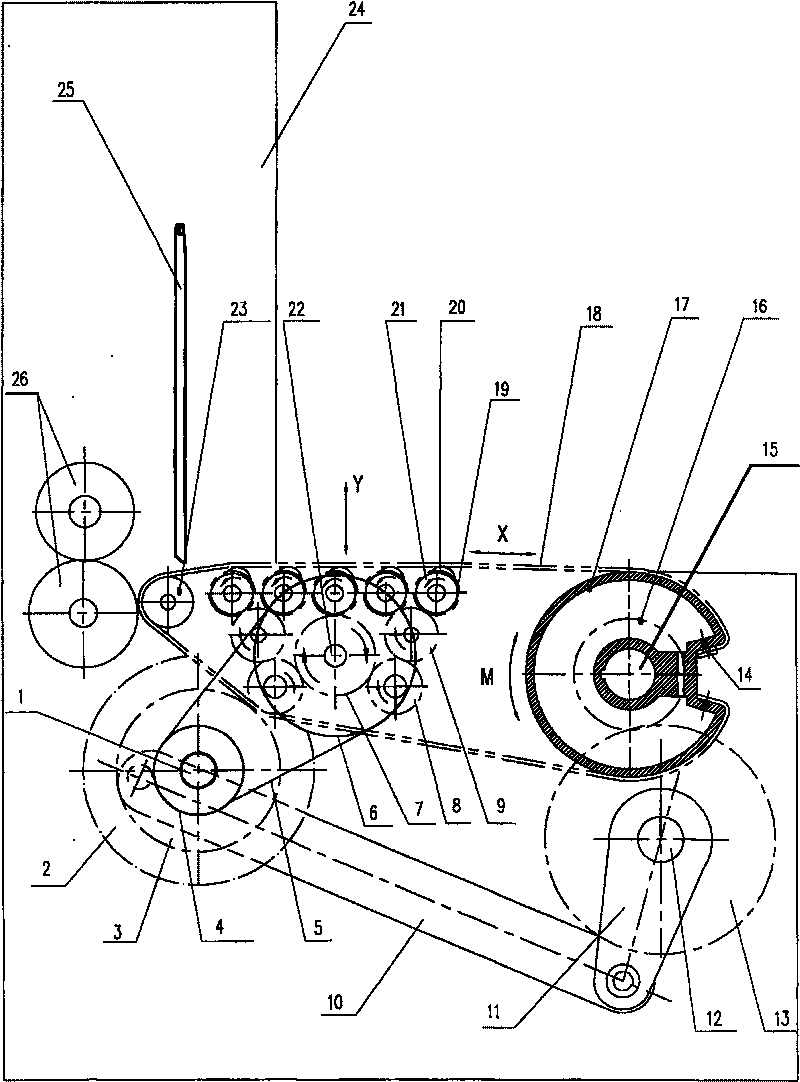

[0013] Embodiment 1: as figure 1 As shown, a belt-type swinging paper feeding device of a high-speed automatic cardboard printing and forming machine includes a frame 24, which is provided with a paper feeding limit plate 25 and a paper feeding rubber roller 26, and is characterized in that it adopts The following five parts:

[0014] (1), frame 24 left lower part is provided with a drive shaft 1, is connected with drive gear 2, eccentric wheel 3 and synchronous belt pulley 4 that match with input power on the drive shaft 1;

[0015] (2), frame 24 lower right is provided with a crankshaft 12, is connected with a crank gear 13 on the crankshaft 12, and one end of crank 11 is connected with crankshaft 12, and the other end is hinged with an end of a connecting rod 10, connects The other end of the rod 10 is hinged with the eccentric wheel 3;

[0016] (3), one end of the upper right part of the frame 24 is provided with a swing shaft 15, a swing wheel 17 and a swing gear 16 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com