Paper feeding equipment and paper feeder

A technology of paper feeding equipment and paper feeding machine, which is applied in transportation and packaging, object supply, pile separation, etc., can solve the problems of low paper feeding speed, low paper feeding accuracy, and inaccurate cardboard feeding, etc., to achieve Good compression and transmission, improved convenience, anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to specific embodiments.

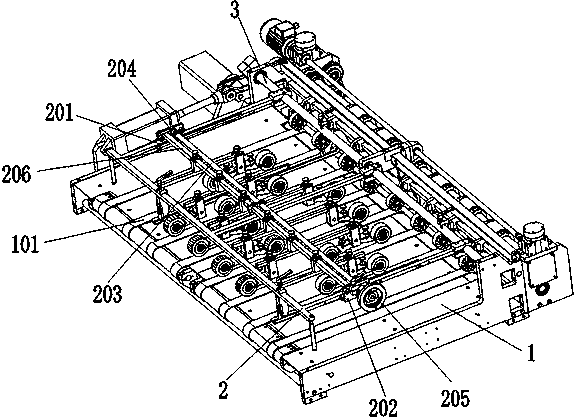

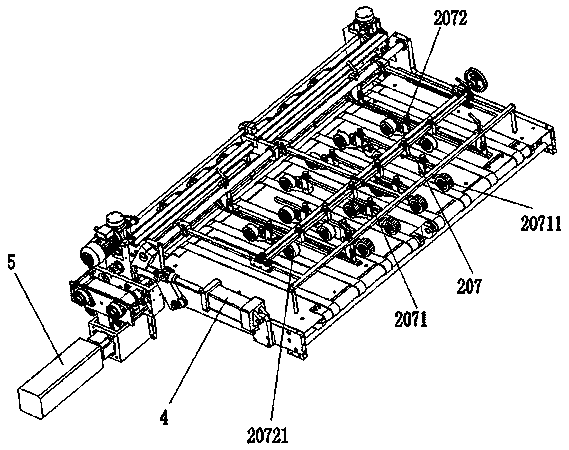

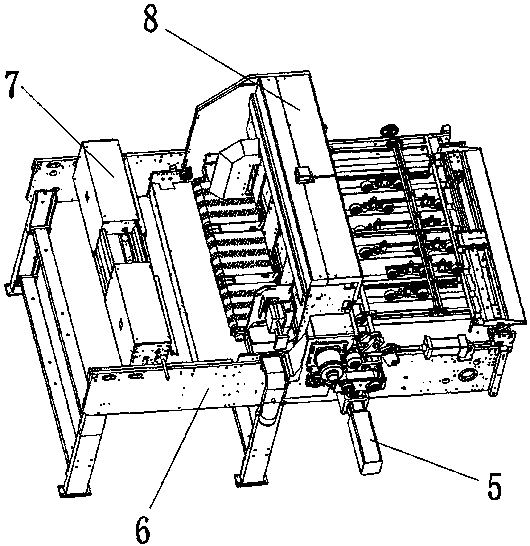

[0045] like Figure 1-Figure 2 As shown, a paper feeding device includes a first stand 1, a first support 2 and a roller 3, the first support 2 is rotatably connected to the first stand 1 through the roller 3, and one end of the roller 3 Connect the first drive unit 4, the first drive unit 4 is used to drive the first bracket 2 to turn over, and the first drive unit 4 is an air cylinder;

[0046] The first stand 1 is provided with a plurality of conveyor belts 101, and the conveyor belts 101 are driven by a second drive unit 5, and the second drive unit 5 is a motor;

[0047] Both sides of the first bracket 2 are provided with a rack 201 and a moving seat 202, the two moving seats 202 are rotatably connected to the same first transmission rod 203, and both ends of the first transmission rod 203 are sleeved with a first gear 204, the first gear 204 is engaged with the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com