Shredder paper feeder with protective cover

A technology of paper feeding device and paper shredder, which is applied in the direction of grain processing, etc., which can solve the problems of affecting work efficiency, prone to slipping paper, and easy roll-up of paper, so as to improve work efficiency, avoid paper slipping, and increase the amount of paper feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

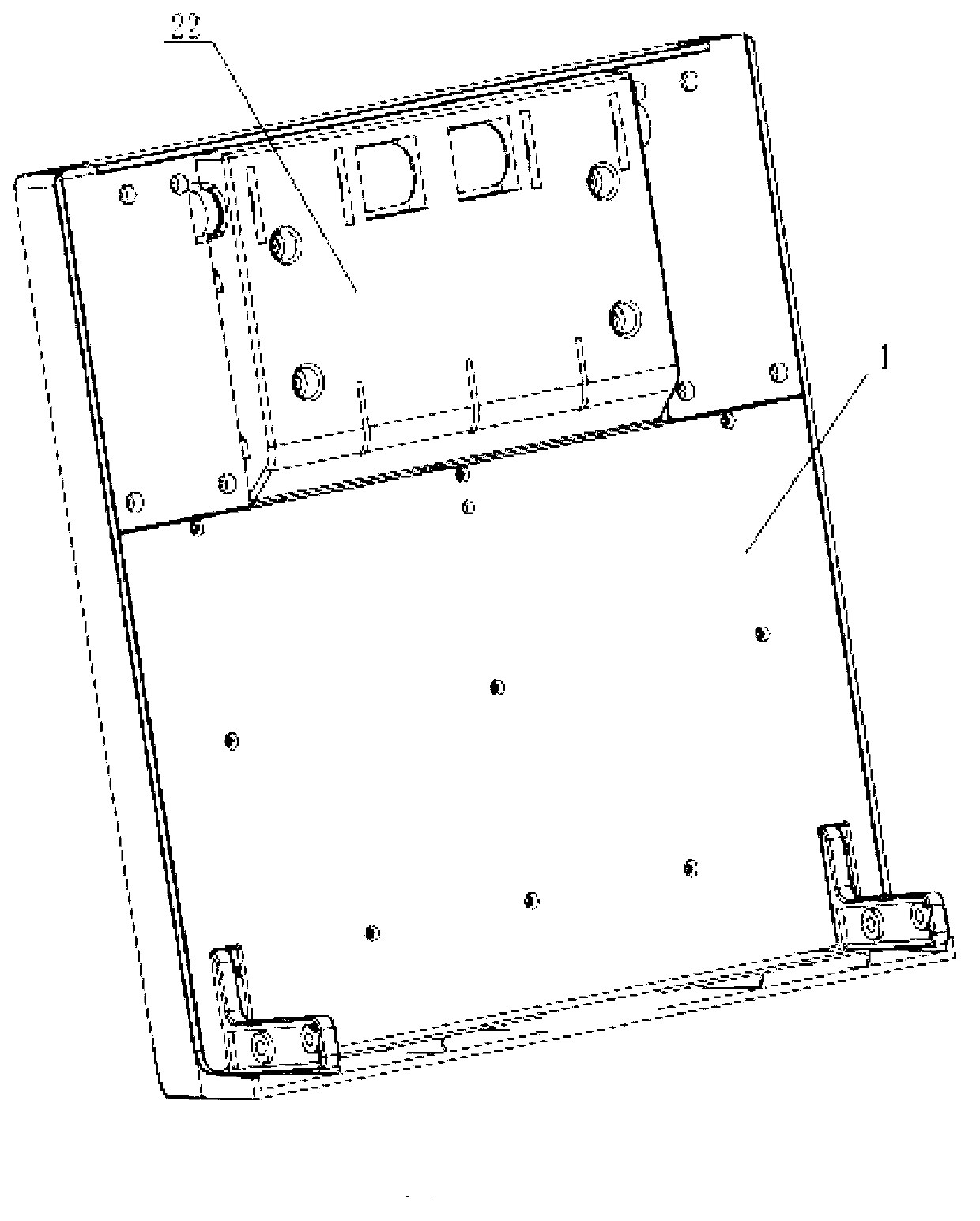

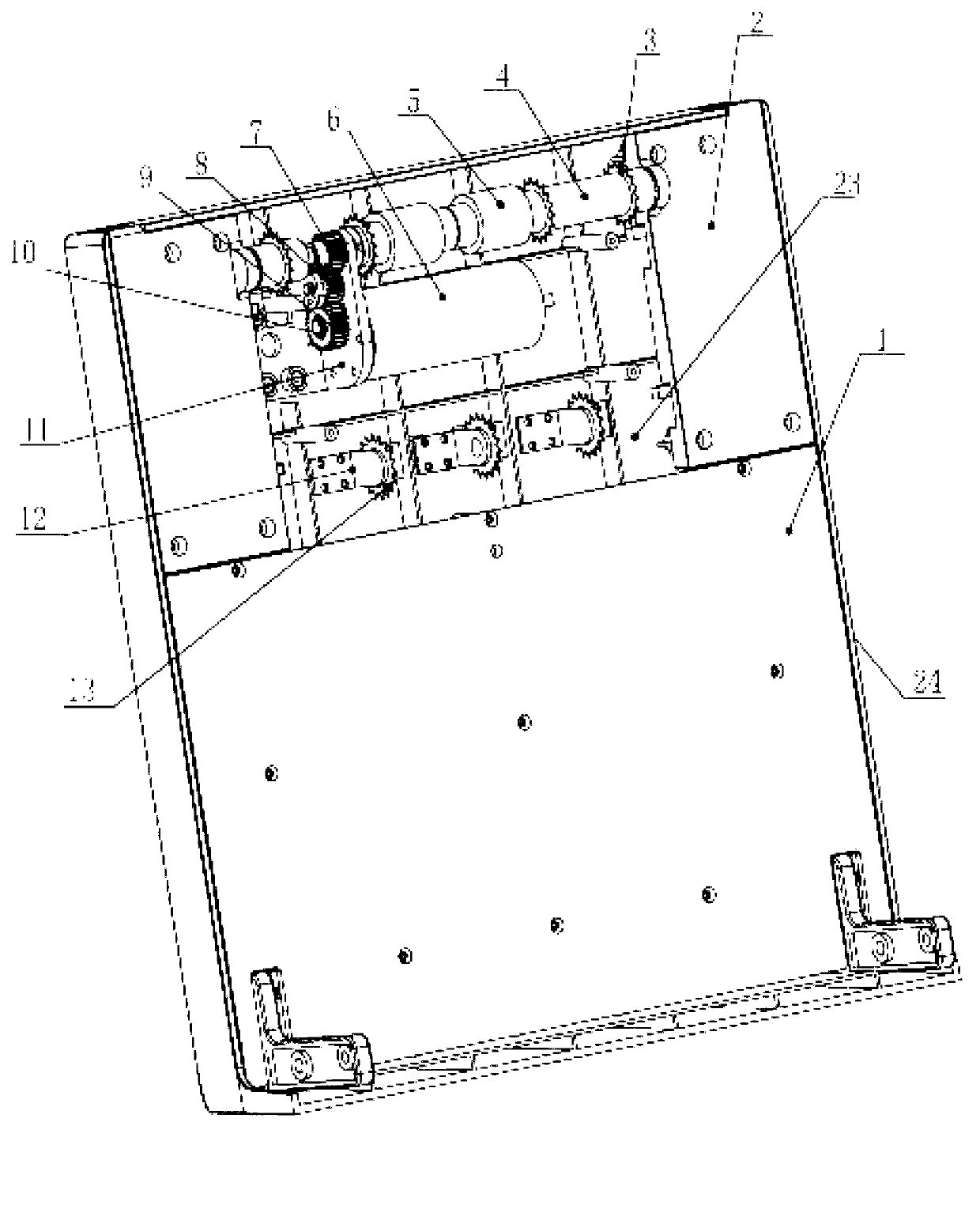

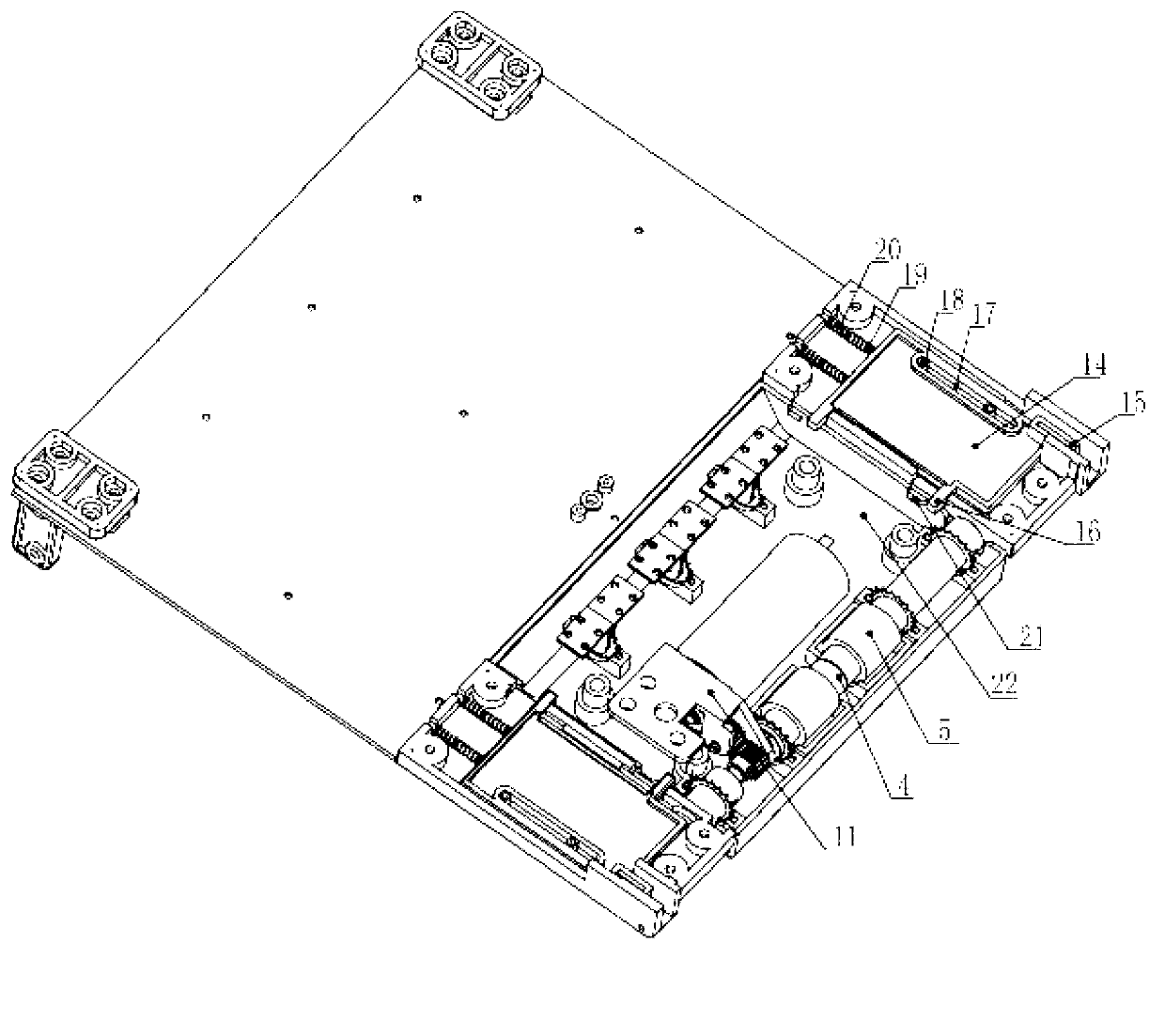

[0019] Install the device of the present invention above the paper placement position of the paper shredder. When in use, put the device down and press it on the paper. The lock buckle on the paper shredder extends into the gap at the front end of the side cover 2 to withstand the buckle. The bar 15 pushes the sliding buckle 14 to slide inwardly, the return spring 20 is compressed, and the protruding bar 16 is embedded in the guide chute 21 of the paper feeding cover 22 at the same time, so that the paper feeding cover 22 is lifted upwards. At this time, the paper feed ratchet 3, the rubber paper feed wheel 5 and the paper feed positioning wheel 13 are exposed on the lower end surface of the paper feed cover 22, and the reduction motor 6 is started to drive the rotating shaft to rotate through gear transmission. The rotation of paper wheel 5 and paper feeding positioning wheel 13 just drives paper to move toward paper inlet, and paper feeding positioning wheel 13 can position p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com