Automatic paper advance device

A technology of automatic paper feeding device and connecting device, which is applied in the direction of transportation and packaging, object separation, object supply, etc., can solve the problems of cost, reduce paper feeding efficiency, increase working time, etc., and achieve paper skewing and increase paper feeding efficiency , the effect of reducing working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

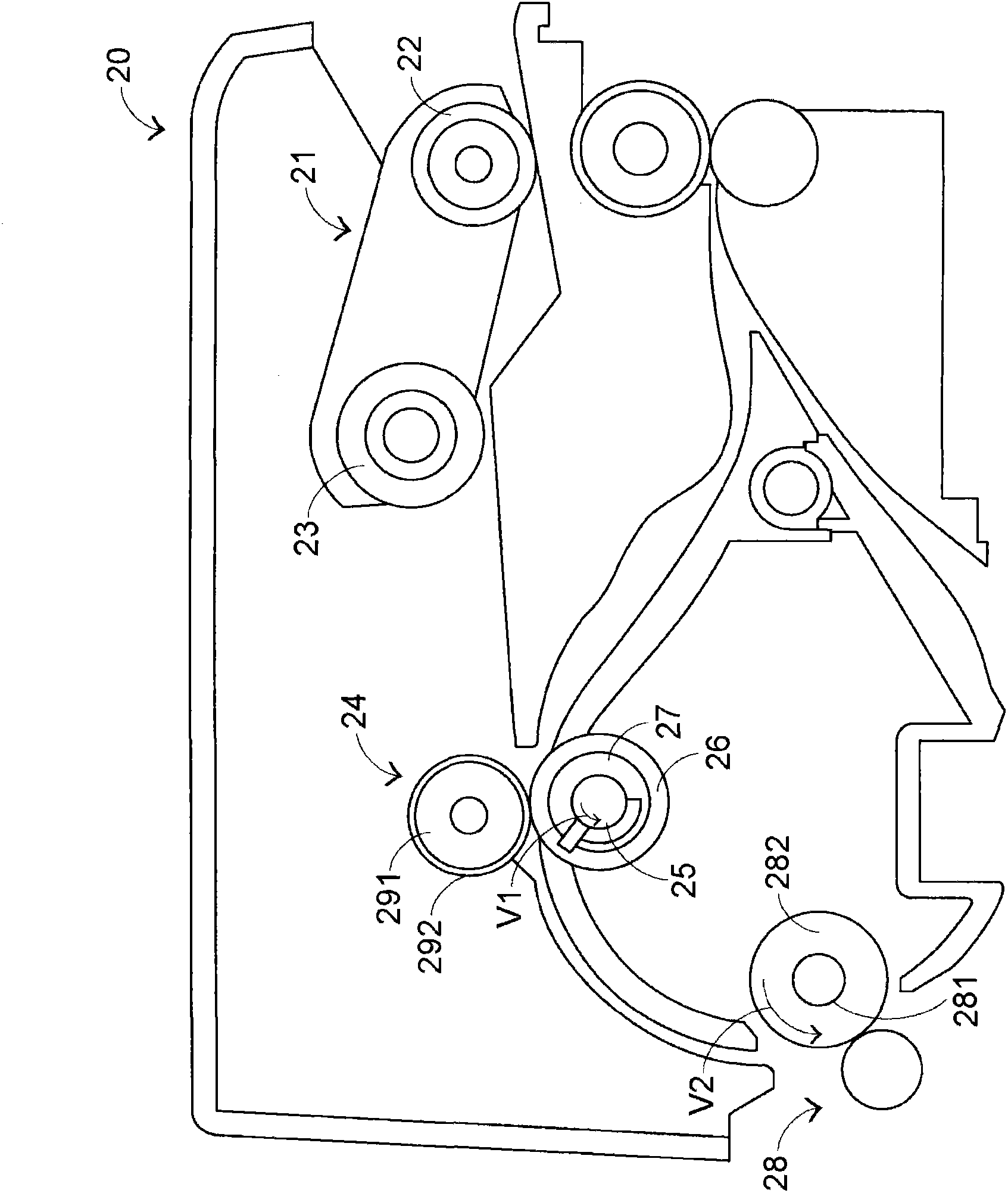

[0091] Please refer to image 3 , image 3 It is a schematic diagram of the automatic paper feeding device of the first embodiment of the present invention. The automatic paper feeding device 20 of the present invention includes a paper fetching device 21, a first transmission roller group 24, a second transmission roller group 28 and a power source (not shown in the figure), wherein the paper fetching device 21 is arranged on the paper feeding At the entrance, the first transport roller set 24 is disposed downstream of the paper picking device 21 , and the second transport roller set 28 is disposed downstream of the first transport roller set 24 .

[0092] Such as image 3 As shown, the paper picking device 21 includes a paper picking roller 22 and a paper separating roller 23 . The first transmission roller set 24 includes a first rotating shaft 25 , a first roller 26 and a power connection device 27 . The second transmission roller set 28 includes a second rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com