a wheel sensor

A wheel sensor and transmitter technology, applied in railway car body components, vehicle route interaction equipment, railway signal and safety, etc., can solve problems such as coil skew, and achieve the effect of solving skew and ensuring the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

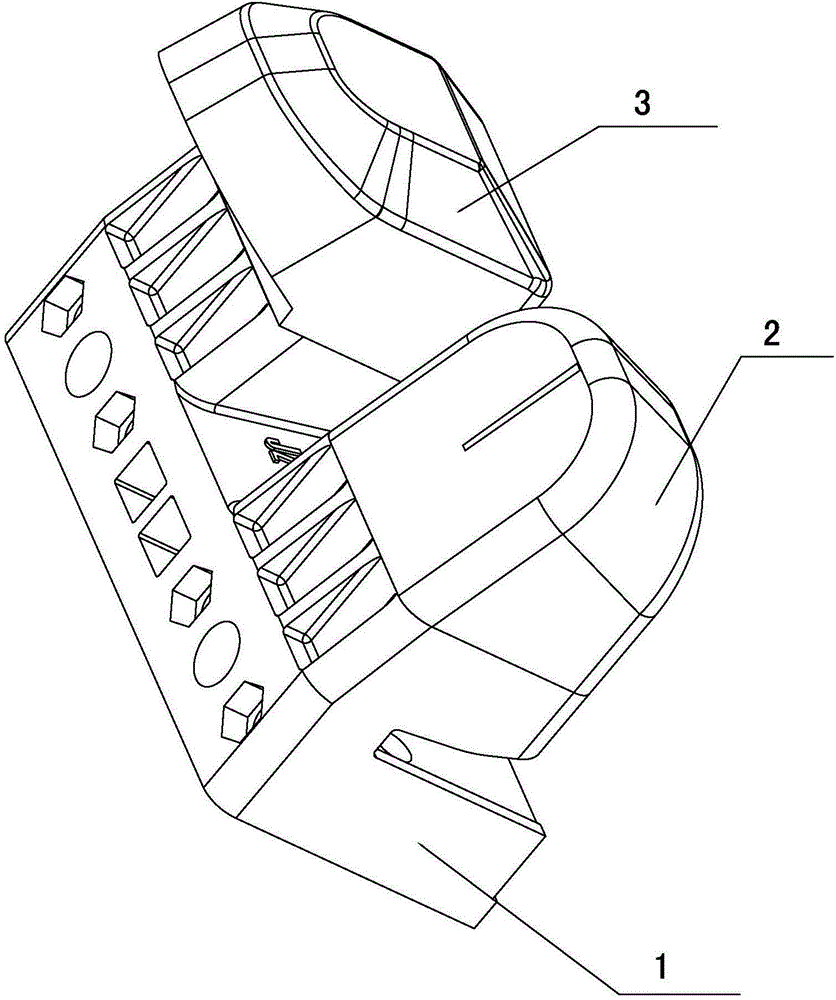

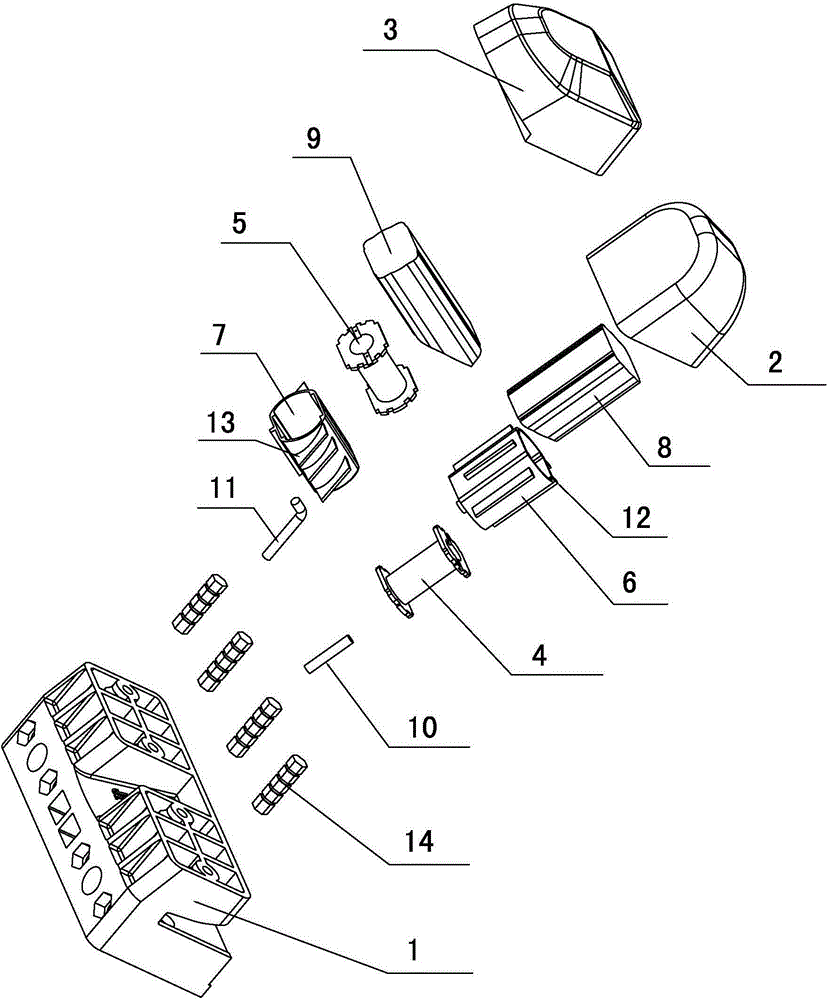

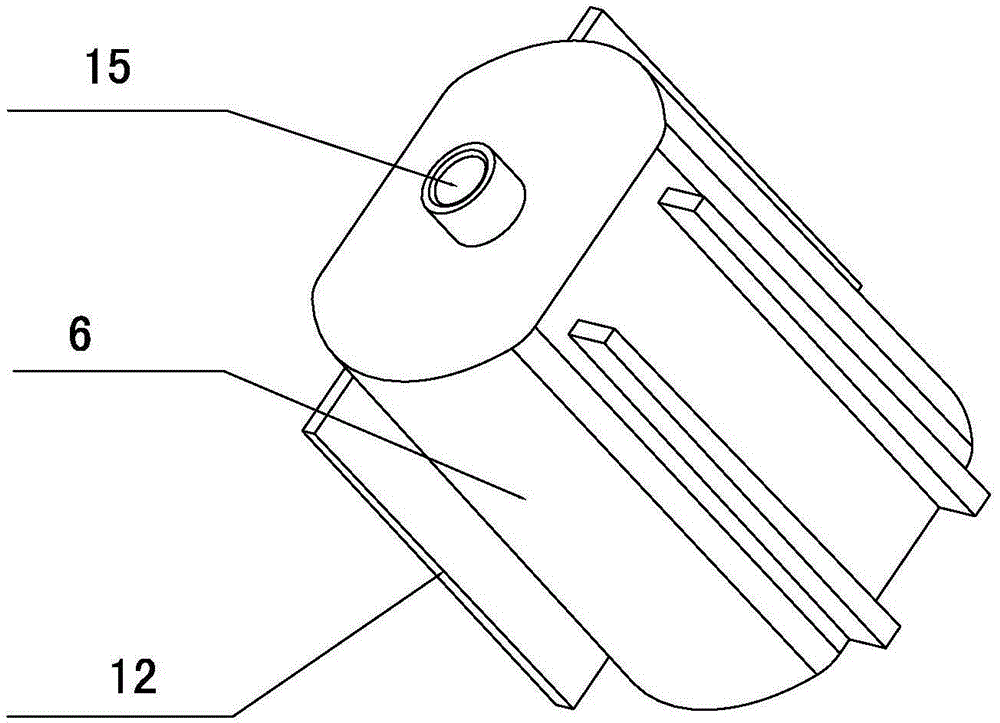

[0021] Please refer to the attached figure 1 to attach Figure 4 , the present invention mainly includes a base 1, a transmitting end shell 2, a receiving end shell 3, and a transmitting end coil and a receiving end coil arranged in the shell, etc., and the transmitting end coil (not shown in the figure) is wound on the transmitting end winding frame 4 Above, the receiving end coil (not shown in the figure) is wound on the receiving end winding frame 5. In this embodiment, the transmitting end winding frame 4 is fixedly arranged in the transmitting end supporting frame 6, and the receiving end winding frame 5 is fixed Set in the receiving end support frame 7, the bottom of the transmitting end support frame 6 is provided with a transmitting end l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com