Printing ink box and printing machine

A technology of ink cartridges and printing tapes, applied in printing and other directions, can solve the problems of low installation efficiency and complicated installation, and achieve the effect of simple and convenient installation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

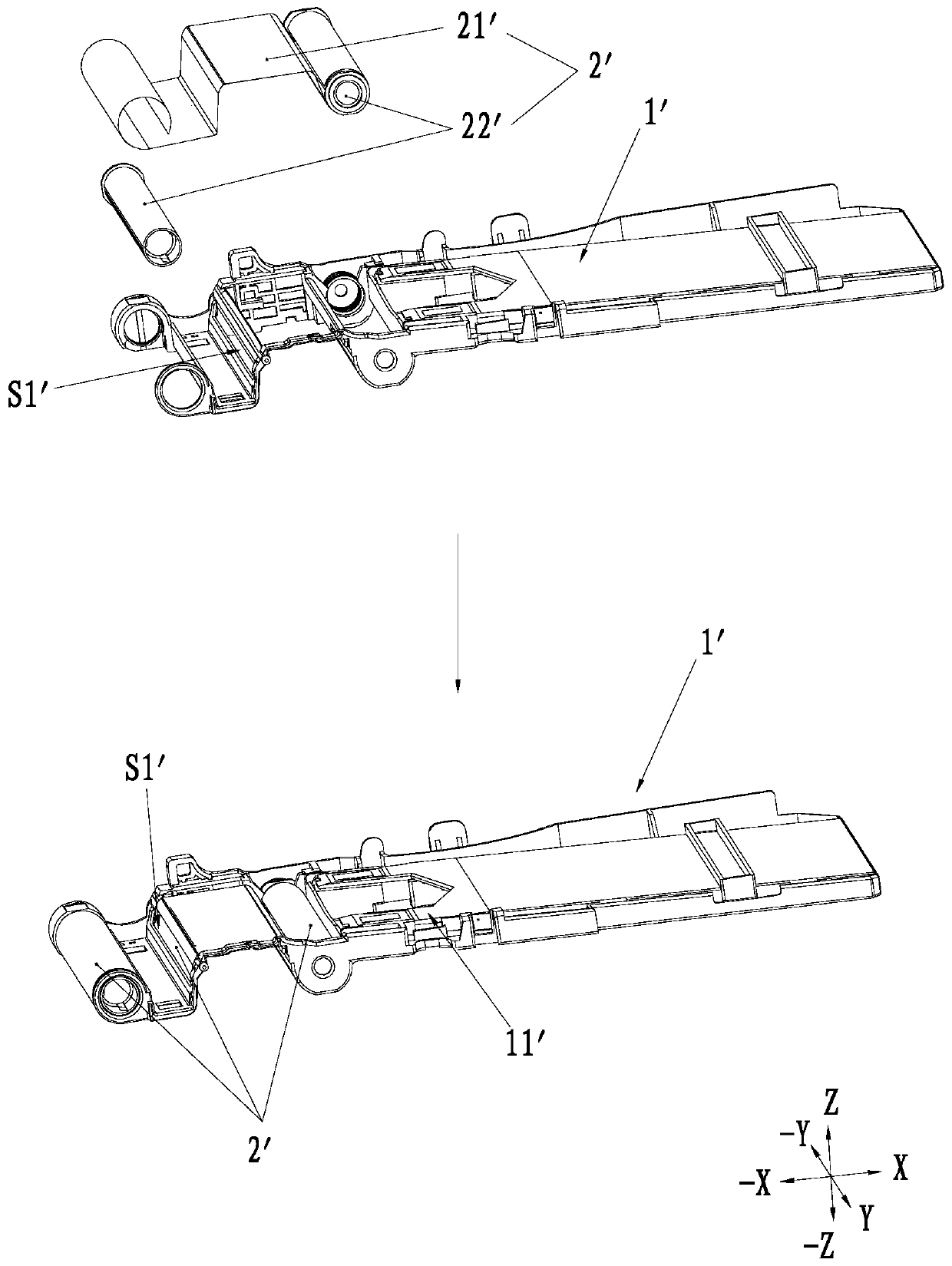

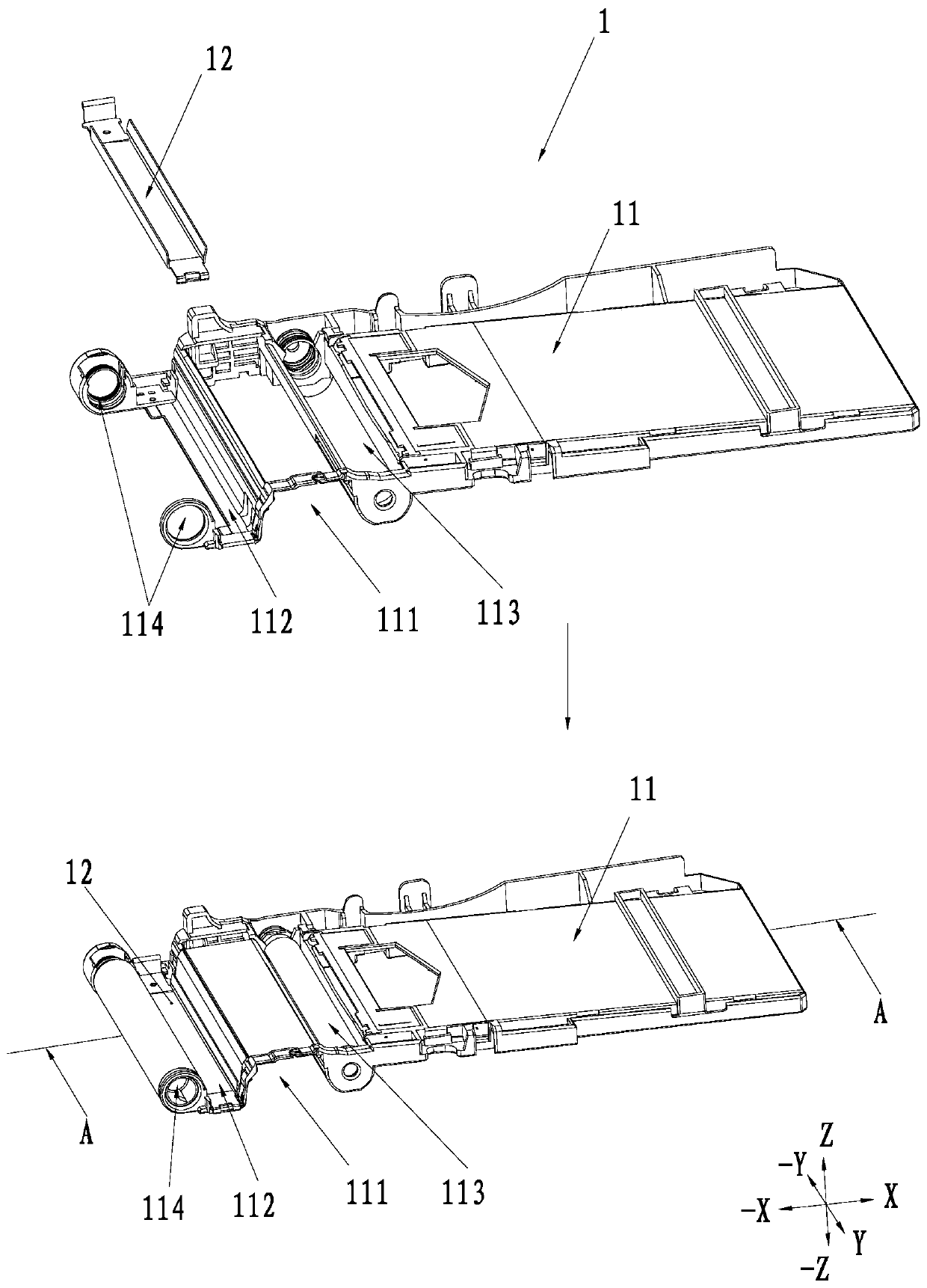

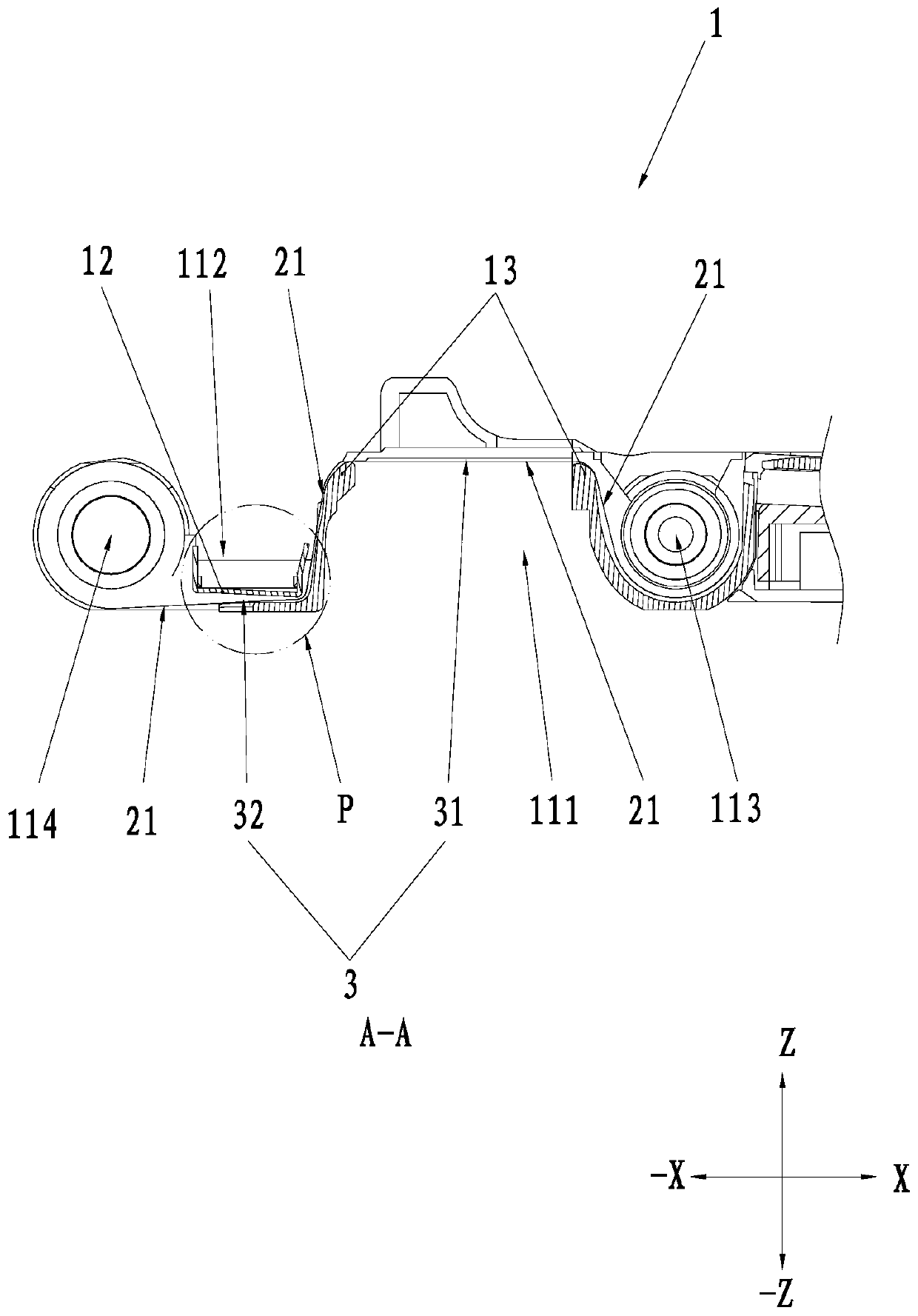

[0039] An implementation of the present invention provides a printing ink cartridge 1 which can be used for loading and fixing a printing ribbon assembly 2 . combine figure 2 , image 3As shown, the box body 1 includes a frame 11 . The frame 11 has a feeding channel, a U-shaped area 111 and a U-shaped groove 112 . Wherein, the U-shaped region 111 has a first opening facing the negative direction side of the second direction, and the U-shaped groove 112 has a second opening facing the positive direction side of the second direction. The U-shaped groove 112 has a pressing device in the second direction. In this embodiment, the pressing device is a pressing plate 12 . The bottom of the U-shaped area 111 is provided with a tension portion 13 . The feeding path 3 includes a first path 31 and a second path 32 connected to the first path 31 . Viewed from the first direction, along the second direction, the first path 31 is located on the positive direction side of the tensionin...

no. 2 example

[0043] Based on the first embodiment, in the second embodiment, combining Figure 4 The pressing plate 12 includes a base plate 51 and guide portions 52 located at both ends of the base plate 51 along the first direction. combine Figure 5 , the guide portion 52 extends along the positive side of the second direction. The substrate 51 has the second path 32 along the negative direction side of the second direction. A guide portion 52 between the first path 31 and the second path 32 forms a third path 33 for communicating with the first path 31 and the second path 32 on a side away from the other guide portion 52 . Wherein, the arc segment between the base plate 51 and the guide portion 52 is transitionally connected. It can be understood that the guide portion 52 can be used as a baffle to separate the U-shaped groove 112 from the printing belt assembly 2 .

[0044] In a second embodiment, combining Figure 5 , the bottom of the pressing plate (that is, the base plate 51 ...

no. 3 example

[0048] Based on the second embodiment, in the third embodiment, combining Figure 7 , the first end of the pressing plate 12 along the third direction has a first fastening member 43, the first fastening member 43 includes a first clamping portion 431 and a second clamping portion 432, the first clamping portion 431 and the second clamping portion The second clamping portion 432 is formed at a first end of the substrate 51 along the third direction, and the first end is an end of the substrate 51 on the positive side of the third direction. The second clamping portion 432 is formed and supported on the first clamping portion 431 , and the first clamping portion 431 and the second clamping portion 432 are arranged at intervals along the second direction. Along the second direction, a clamping groove 433 is sandwiched between the first clamping portion 431 and the second clamping portion 432 .

[0049] In a third embodiment, combining Figure 8 , there is a second fastening me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com