Automatic paper feeding machine

A paper machine, automatic technology, applied in the direction of thin material handling, transportation and packaging, object supply, etc., can solve the problems of aggravating the work intensity and tension of workers, unable to guarantee paper quality, and low paper feeding efficiency, etc., to improve paper feeding. Efficiency, high degree of automation, fast paper loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

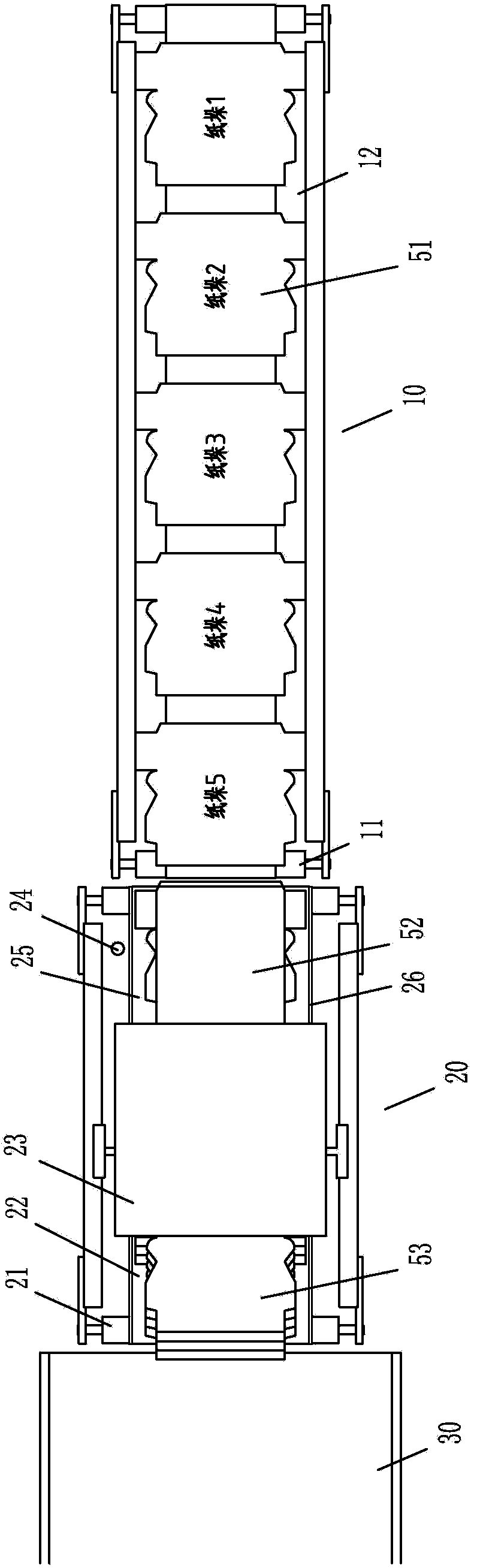

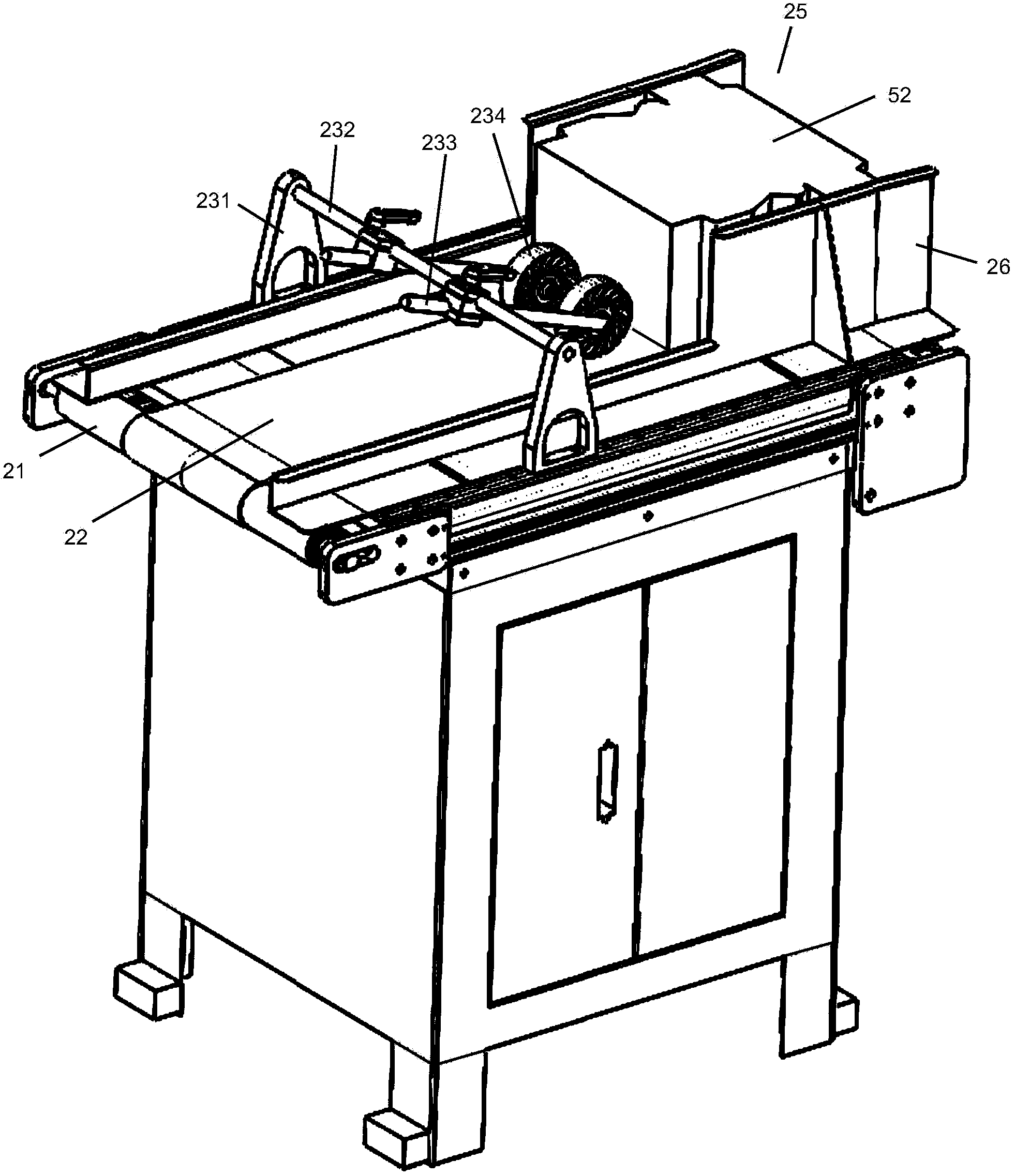

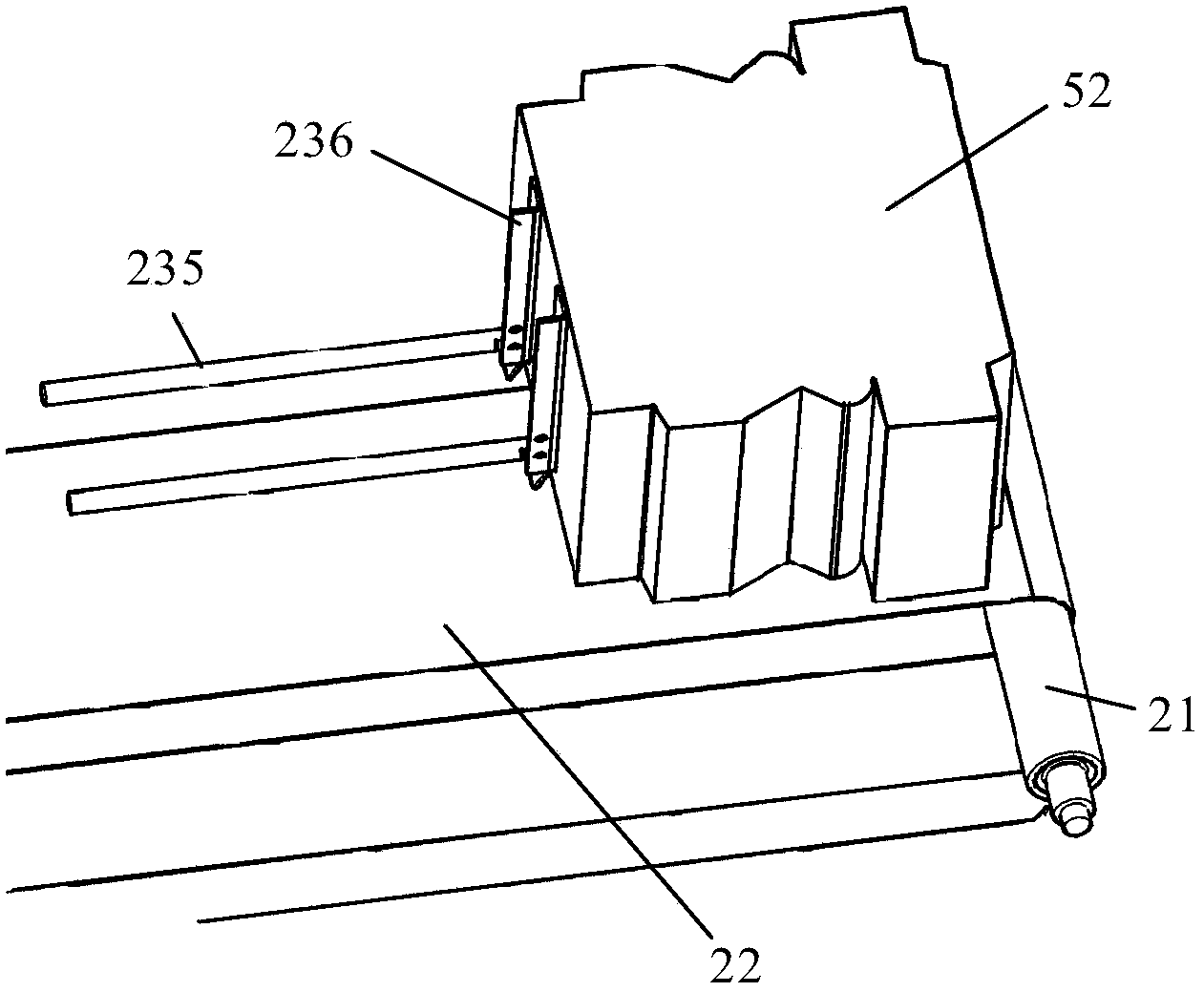

[0021] Such as figure 1 As shown, the automatic paper loading machine of the present invention includes a paper stack placement table 10 for intermittently conveying paper stacks and a fish scale conversion table 20 that continuously spreads the incoming paper stacks into fish scales and sends them out. The output of the paper stack placement table 10 end is set corresponding to the input end of the fish scale conversion table 20, and the output end of the fish scale conversion table 20 is set corresponding to the input end of the printing and packaging machine 30. Generally, the printing and packaging machine 30 includes a sheet feeding mechanism, and the fish scale conversion The output terminal of platform 20 can be directly set corresponding to the input terminal of the sheet-feeding mechanism, and the signal ports of the paper pile placing platform 10 and the fish scale conversion platform 20 are connected with the main control device (not shown in the figure) respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com