Paper receiving device for corrugated paper board production line

A corrugated cardboard and production line technology, applied in the direction of mechanical processing/deformation, can solve problems such as trouble, pressing cardboard, and easy slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

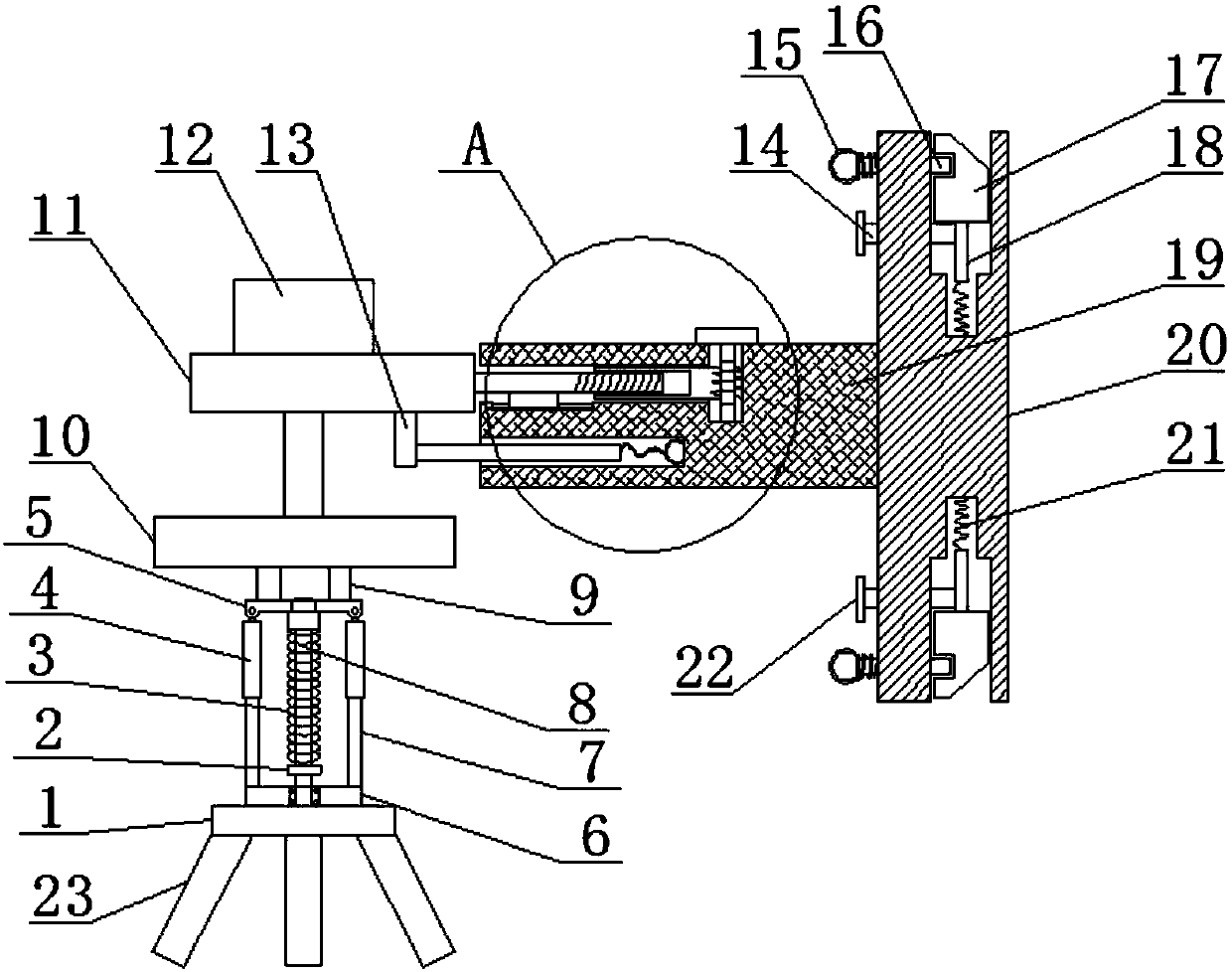

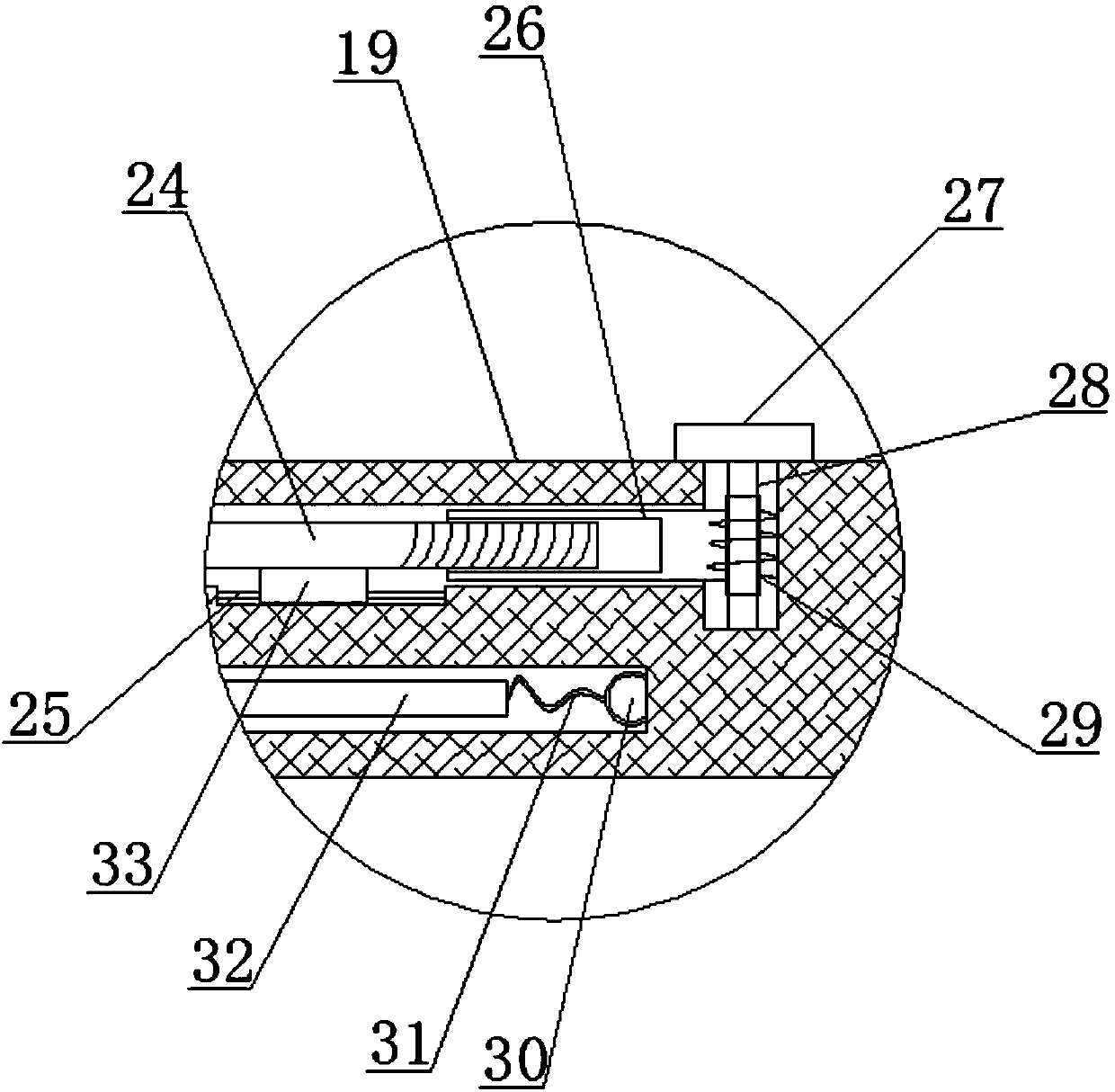

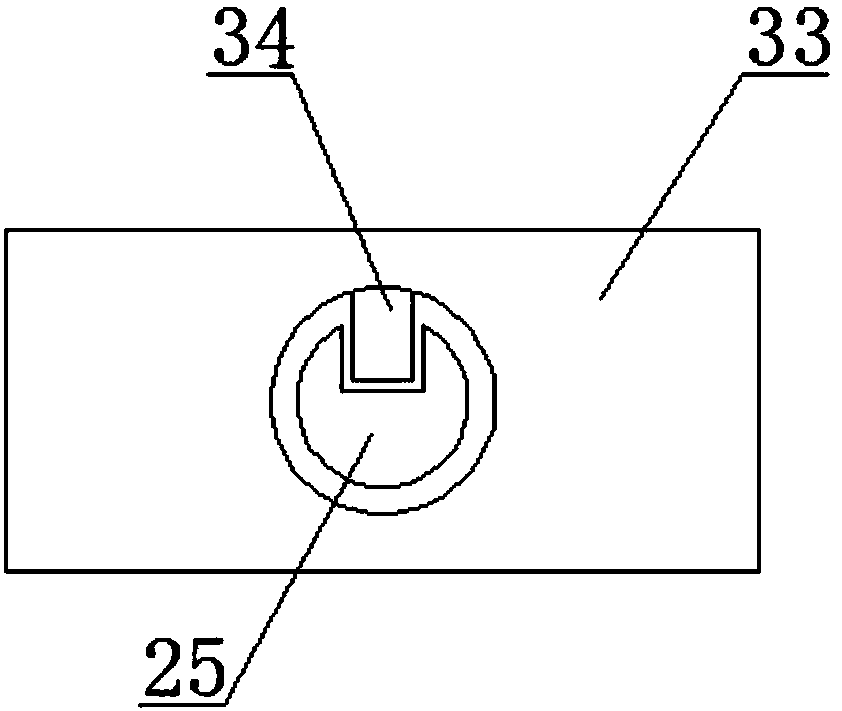

[0018] Reference Figure 1-3 , A paper splicing device for a corrugated cardboard production line, including a fixed plate 20. The upper and lower ends of the fixed plate 20 are provided with slide grooves. When in use, the operator fixes the fixed plate 20 to the paper splicing frame of the corrugated cardboard production line In the fixed groove, two sliding grooves are provided with insert blocks 17, the inner walls of the two sliding grooves are equipped with limit cavities, and the limit cavity is provided with a guide rod 18, which is fixedly connected by a first elastic device 21 On the inner wall of the limit cavity, the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com