Splicer for corrugated board production line

A corrugated cardboard and production line technology, applied in the field of printing machinery, can solve the problems of pressing cardboard, troublesome, easy to slip, etc., to achieve the effect of stable rotation, not easy to slip, and improve paper feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

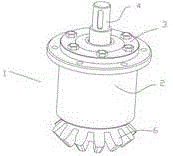

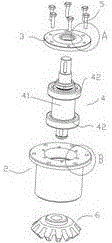

[0017] Such as Figure 1 to Figure 5 As shown, the paper splicing device 1 for a corrugated cardboard production line includes a fixed shaft cylinder 2, a drive shaft body 4 is arranged inside the fixed shaft body 2, and an annular fixed cover plate 3 is arranged above the drive shaft body 4. The fixed shaft 2 includes a cylindrical shaft main body 21, the top of the shaft main body 21 is provided with an annular shaft flange 22 extending outwards, and a fixed circle is arranged on the circumference of the shaft flange 22. A fixed circular hole array composed of holes 23 and a connected circular hole array composed of connecting circular holes 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com