A ps-converter incomplete exchange matte blowing method

A converter and matte technology, applied in the field of blowing, can solve the problems of large number of PS-converters, high operation failure rate, and large occupied space, and achieve shortened blowing time, high air supply rate, and occupied space Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

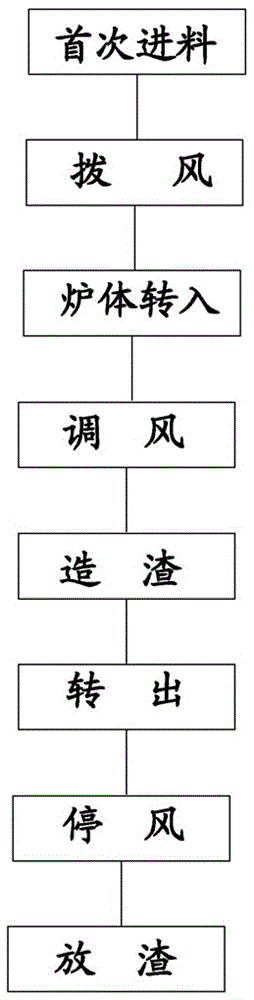

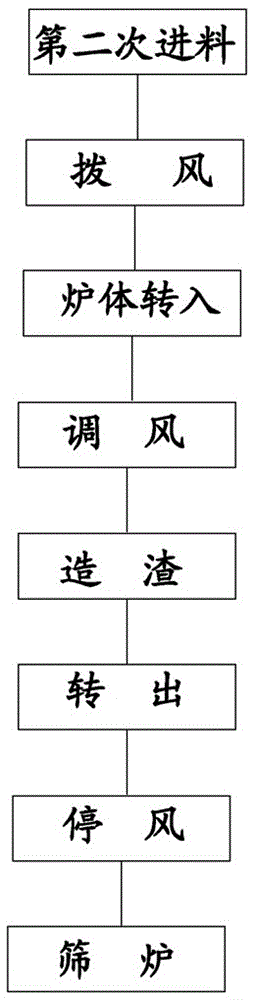

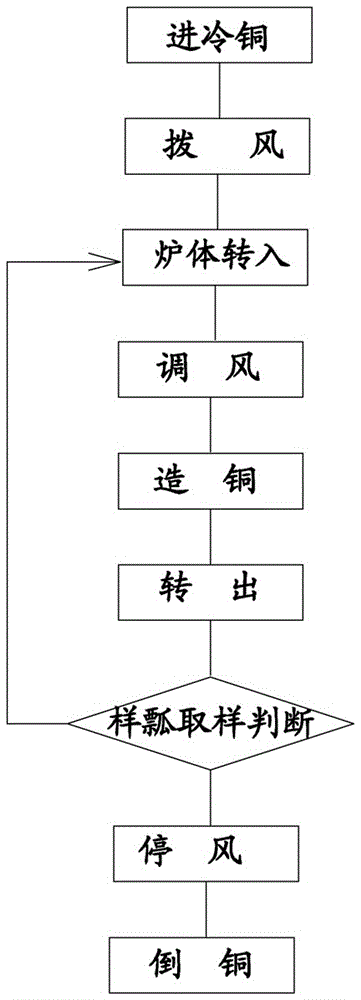

[0042] see Figure 1-4 , the present invention includes the following steps:

[0043] The first step: equipped with four PS-converters and two high-pressure blowers;

[0044] Step 2: Divide the four PS-converters into two groups at random, wherein the first group is labeled No. 1 furnace and No. 2 furnace, and the second group is labeled No. 3 furnace and No. 4 furnace. figure 1 Among them, A represents No. 1 furnace, B represents No. 2 furnace, C represents No. 3 furnace, and D represents No. 4 furnace, and each group of PS-converters cooperates with a high-pressure blower respectively;

[0045] Step 3: After the PS-converter is heated up, start the high-pressure blower, so that each PS-converter is in a hot state to be smelted;

[0046] Step 4: Adjust the blowing process of the two PS-converters in each group of PS-converters, so that the blowing operation of each PS-converter is divided into three stages: the first slagging period (S1 period), the second Secondary slaggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com