Flow control method for powder blowing in molten iron dephosphorization pretreatment process

A technology of molten iron pretreatment and flow control, which is applied in the direction of flow control using electric devices, etc., can solve problems such as blockage and powder blockage of pipelines, and achieve the effects of improving dephosphorization efficiency, avoiding blockage of pipelines, and shortening blowing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

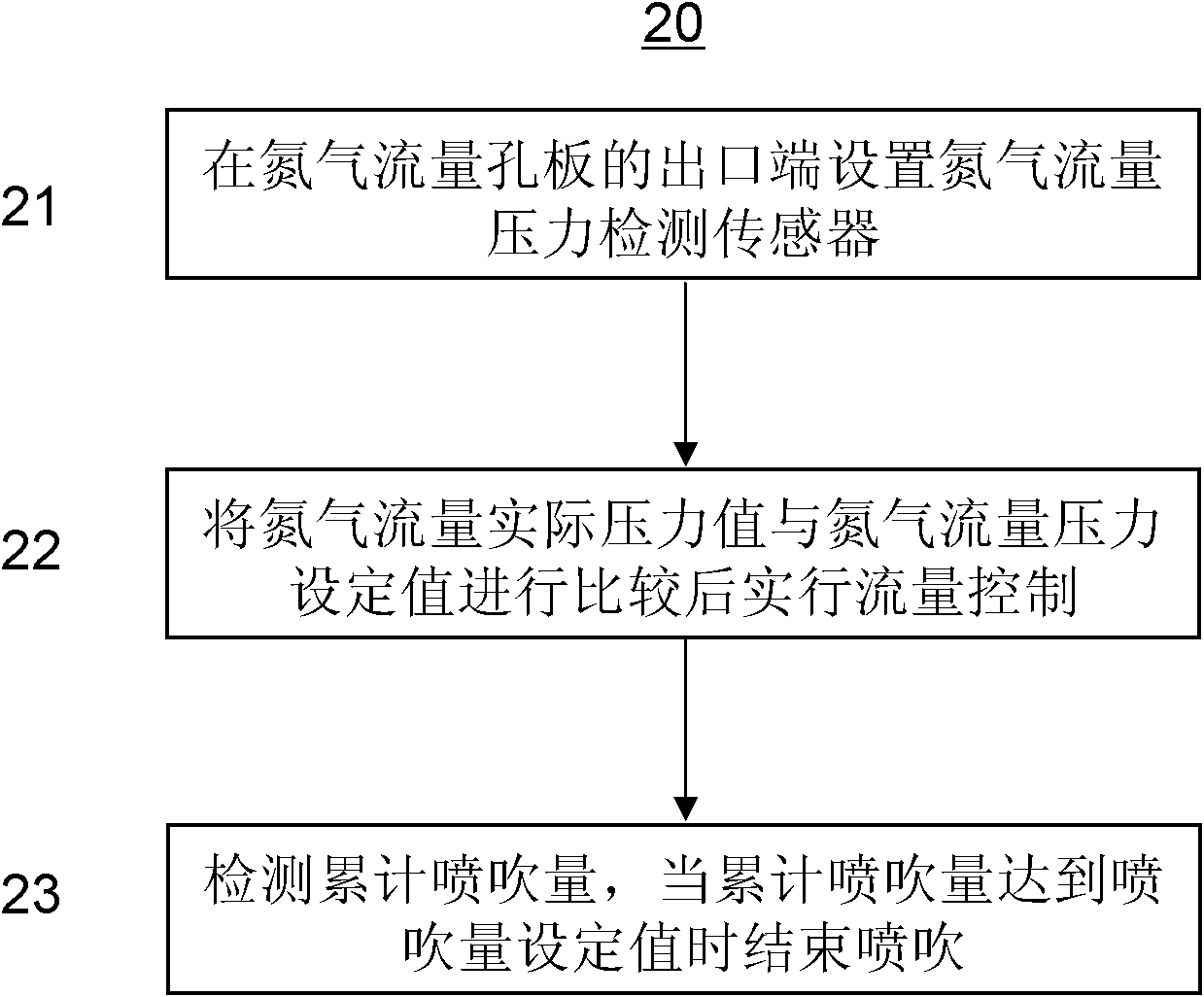

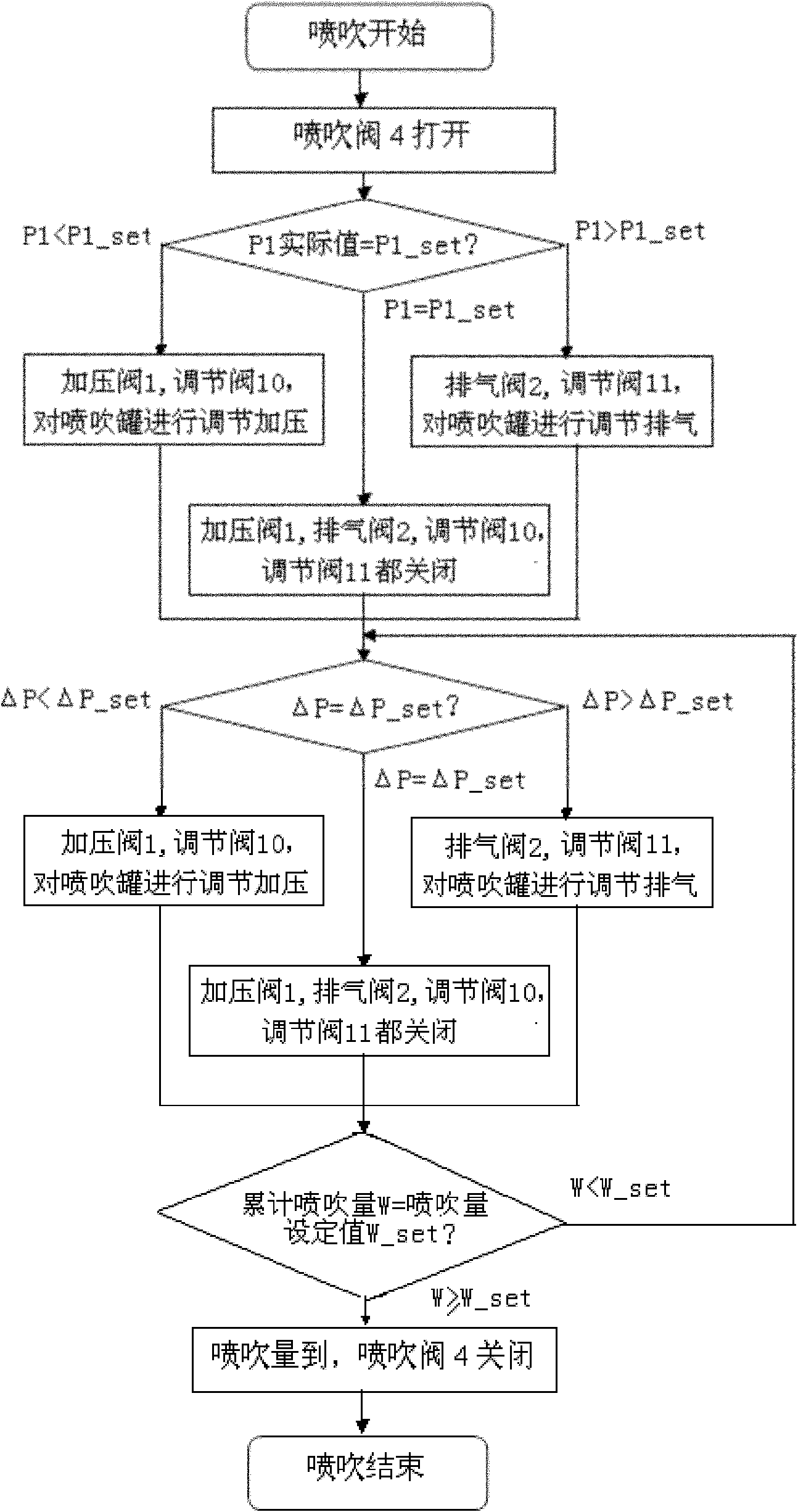

[0028] see image 3 Shown is a flow control method 20 of powder injection in the molten iron pretreatment dephosphorization process, the specific steps of the flow control method are:

[0029] 21. Install a nitrogen flow pressure detection sensor at the outlet of the nitrogen flow orifice to generate the actual pressure value of the nitrogen flow;

[0030] 22. Transmit the actual pressure value of the nitrogen flow to the programmable controller for comparison with the set value of the nitrogen flow pressure and then implement flow control;

[0031] 23. Detect the cumulative injection volume, and end the injection when the cumulative injection volume reaches the set value of the injection volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com