Method for judging end point time of copper smelting of converter

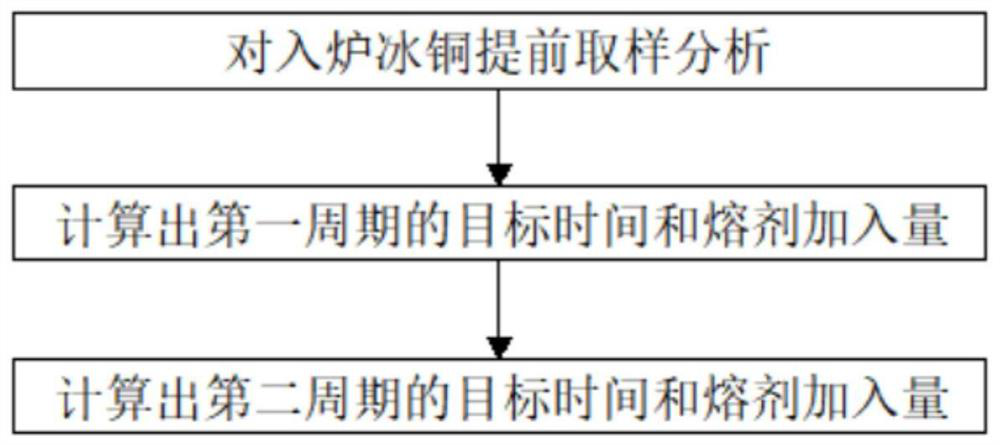

A technology of terminal time and converter, which is applied in the field of judging the terminal time of converter copper smelting, and can solve problems such as waste of smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] After the matte is discharged from the previous process, it is put into the matte bag, and samples are taken and sent to the laboratory to analyze the copper content, iron content, and sulfur content, and the mass of the matte in the bag is obtained through the crane weighing system. After obtaining the above Mathematical modeling is carried out by the following formula after each data

[0066] Take a set of conventional data here for calculation demonstration

[0067] Matte weight 20t, copper content 49.12%, iron content 20.84% sulfur content 24.06%, iron-silicon ratio 1.4, calculated by formula:

[0068] Matte iron content in this group Kg=matte weight 20t*1000*iron content 20.84% / 100=4168Kg;

[0069] The molar amount of oxygen required for this group of matte Kmol = iron content 4168Kg / 55.85*1.5 = 112Kmol;

[0070] Oxygen required for this group of matte Nm 3 =Oxygen molar mass 112Kmol*22.4=2508Nm 3 ;

[0071] The amount of air required for this group of matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com